Lead-free ferroelectric upconversion fluorescent material and its preparation method and application

A fluorescent material and ferroelectric technology, applied in luminescent materials, chemical instruments and methods, instruments, etc., to achieve the effects of reducing production costs, protecting rare earth resources, and increasing luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

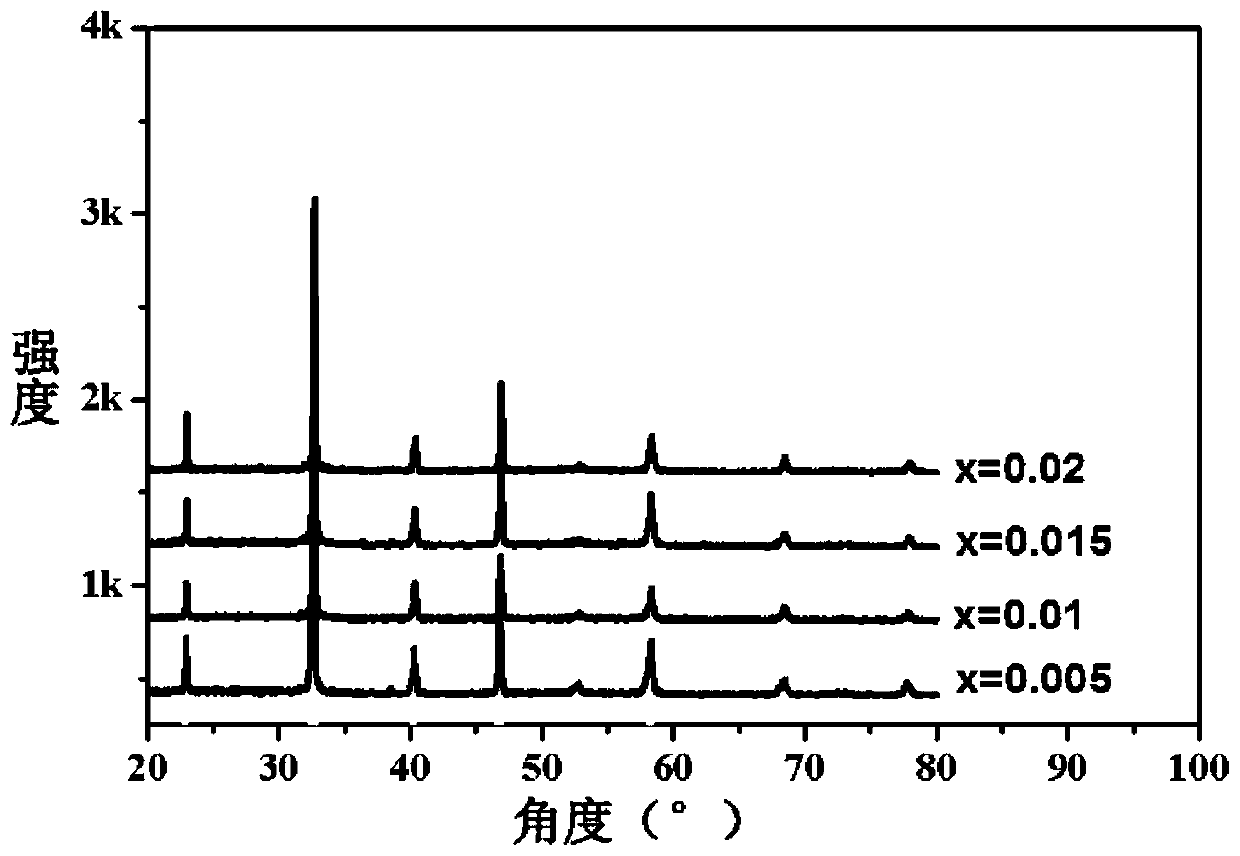

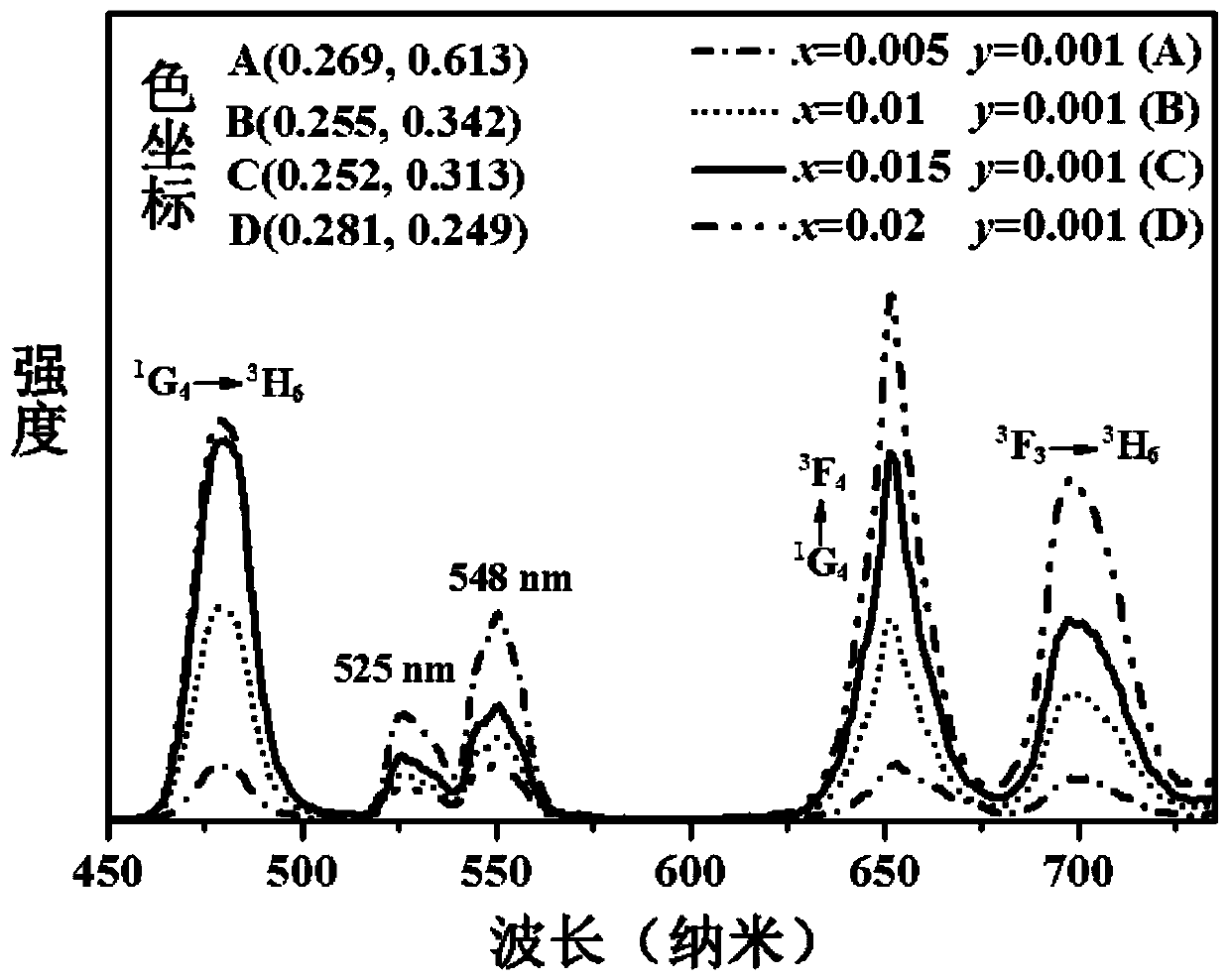

[0029] Using 99.8% pure Na 2 CO 3 , 99.9% Bi 2 o 3 ,99.8% TiO 2 , 99.9% Tm 2 o 3 and 99.9% Yb 2 o 3 As raw materials, five groups of lead-free ferroelectric upconversion fluorescent ceramics with different components were prepared, according to the chemical formula Na 0.5 Bi 0.499- x Yb x T m 0.001 TiO 3 (x=0.005, 0.01, 0.015, 0.02) are weighed separately, put into a ball mill tank and mixed for ball milling, ball milling conditions: the volume ratio of raw materials, agate ball volume, and ball milling medium absolute ethanol is approximately equal to 1:1 : 1.5, it was ball milled for 12 hours, and the raw material after ball milling was put into an oven and baked at 80° C. for 4 hours. Afterwards, use a tablet machine to press the dried raw materials into raw material embryos with a diameter of 40 mm, and then put the pressed embryos into a KBF1400 box furnace for pre-calcination. The pre-calcination condition is 850 ° C for 2 hours. , and then crush the pre-fi...

Embodiment 2

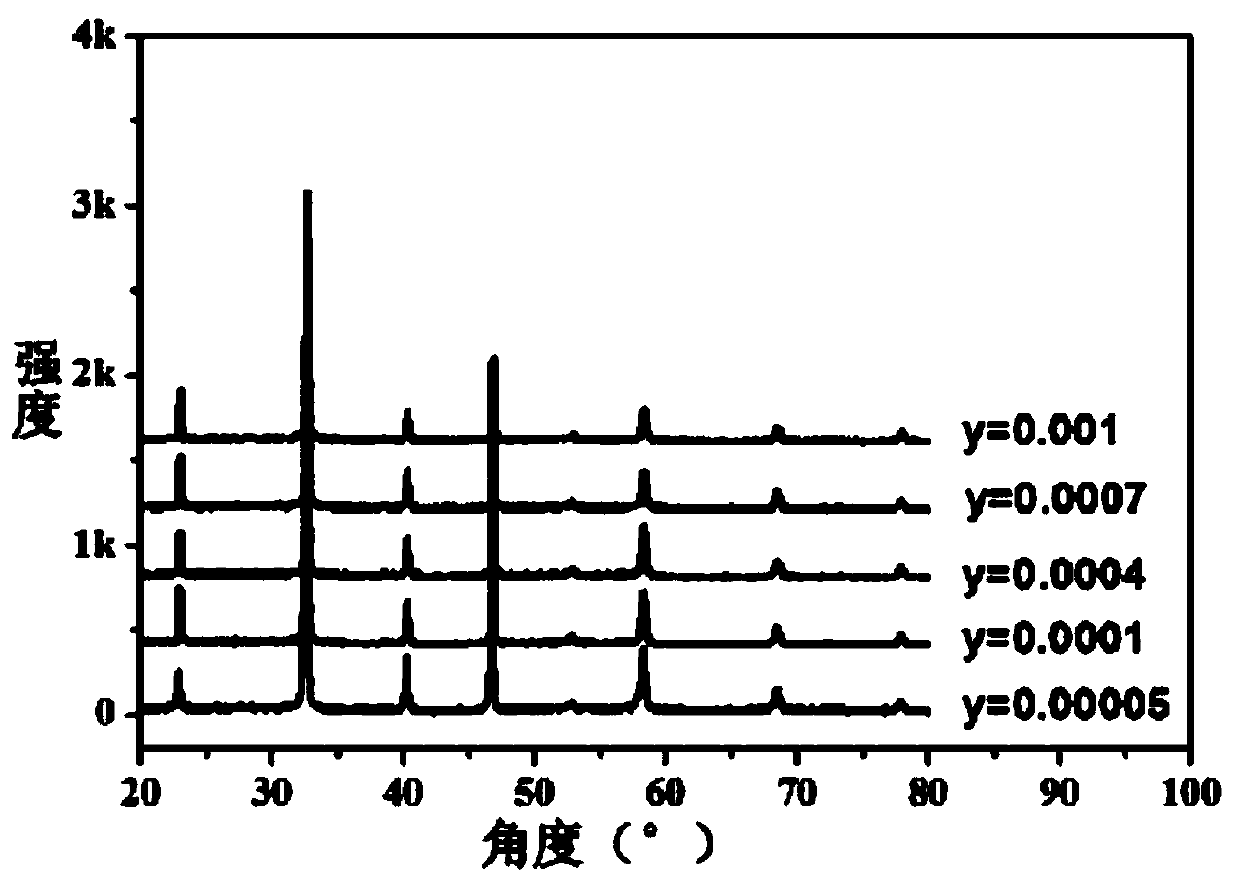

[0031] Using 99.8% pure Na 2 CO 3 , 99.9% Bi 2 o 3 ,99.8% TiO 2 , 99.9% Tm 2 o 3 and 99.9% Yb 2 o 3 Prepare five groups of lead-free ferroelectric upconversion fluorescent ceramics with different components as raw materials, according to the chemical formula Na 0.5 Bi 0.499- x Yb x T m 0.001 TiO 3 (y=0.00005, 0.0001, 0.0004, 0.0007, 0.001) are weighed respectively, put into a ball mill tank and mix ball milling, ball milling conditions: the volume ratio of raw material, agate ball volume, ball milling medium anhydrous ethanol is approximately equal to 1 : 1.2: 1, ball mill it for 12 hours, put the raw material after ball milling into an oven and bake at 80°C for 4 hours. Afterwards, use a tablet machine to press the dried raw materials into raw material embryos with a diameter of 40mm, and then put the pressed embryos into a KBF1400 box furnace for pre-calcination. The pre-calcination condition is 750 ° C for 2 hours. , and then crush the pre-fired block sample, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com