Cleaning treatment method for waste petroleum catalyst

A clean treatment and catalyst technology, applied in the direction of improving process efficiency, etc., can solve the problems of failure to achieve comprehensive utilization of vanadium resources, oil cannot be used directly as a heat source, poor deoiling effect, etc., and achieve clean reuse, energy saving, The effect of reducing the generation of solid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

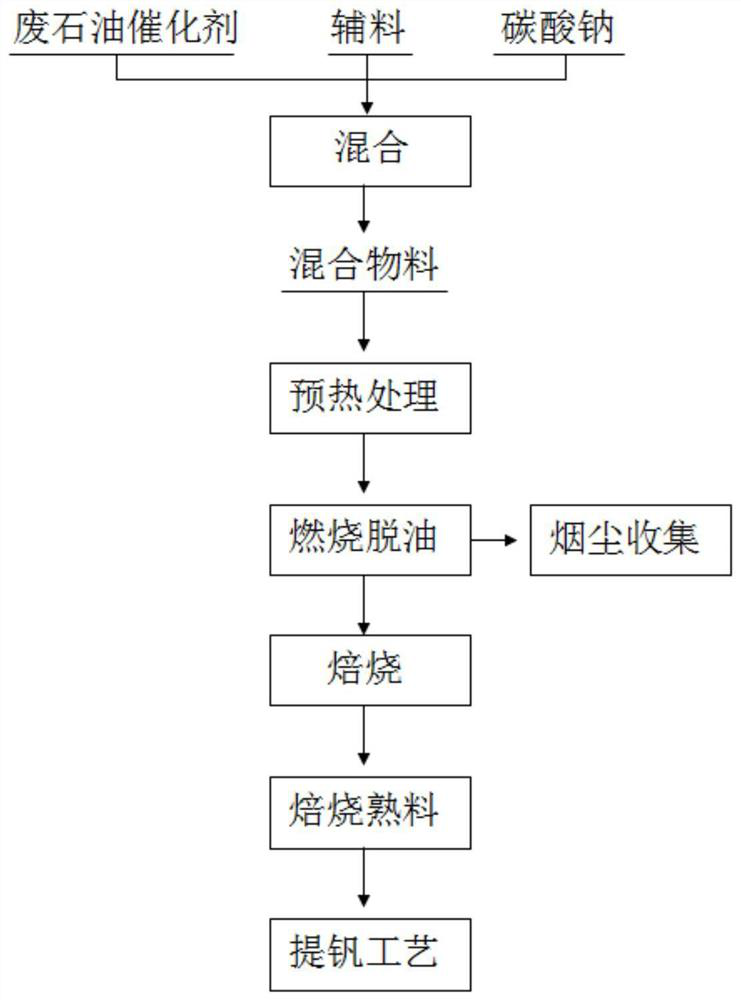

[0028] Such as figure 1 Shown, a kind of cleaning treatment method of waste petroleum catalyst comprises the steps:

[0029] (1) Mix vanadium-containing steel slag and waste petroleum catalyst at a mass ratio of 50:100, then add a certain amount of sodium carbonate and mix, and stir to obtain a mixed material;

[0030] (2) Send the mixed material into the preheating kiln for preheating treatment, and the preheating temperature is less than 200°C;

[0031] (3) Send the preheated mixture into the combustion furnace for combustion and deoiling treatment at a temperature of 650°C and burn for 60 minutes;

[0032] (4) Send the mixed material through the deoiling treatment of the combustion furnace into the rotary kiln for roasting, and roast at 880° C. for 120 minutes to obtain roasted clinker;

[0033] (5) The roasted clinker obtained after being roasted in a rotary kiln is crushed to obtain clinker powder, and the clinker powder is supplied to the subsequent vanadium extraction...

Embodiment 2

[0037] A cleaning method for waste petroleum catalysts, comprising the steps of:

[0038] (1) Mix vanadium extraction tailings and waste petroleum catalyst at a mass ratio of 100:100, then add a certain amount of sodium carbonate to mix, and stir evenly to obtain a mixed material;

[0039] (2) Send the mixed material into the preheating kiln for preheating treatment, and the preheating temperature is less than 200°C;

[0040] (3) Send the preheated mixed material into the combustion furnace for combustion and deoiling treatment at a temperature of 600°C and burn for 50 minutes;

[0041] (4) Send the mixed material through the deoiling treatment of the combustion furnace into the rotary kiln for roasting, and roast at 850° C. for 120 minutes to obtain roasted clinker;

[0042] (5) The roasted clinker obtained after being roasted in a rotary kiln is crushed to obtain clinker powder, and the clinker powder is supplied to the subsequent vanadium extraction operation to obtain vanad...

Embodiment 3

[0046] A cleaning method for waste petroleum catalysts, comprising the steps of:

[0047] (1) Mix vanadium slag and waste petroleum catalyst in a mass ratio of 50:150, then add a certain amount of sodium carbonate to mix, and stir to obtain a mixed material;

[0048] (2) Send the mixed material into the preheating kiln for preheating treatment, and the preheating temperature is less than 200°C;

[0049] (3) Send the preheated mixture into the combustion furnace for combustion and deoiling treatment at a temperature of 650°C and burn for 60 minutes;

[0050] (4) Send the mixed material that has been deoiled by the combustion furnace into a rotary kiln for roasting, and roast at 800° C. for 90 minutes to obtain roasted clinker;

[0051] (5) The roasted clinker obtained after being roasted in a rotary kiln is crushed to obtain clinker powder, and the clinker powder is supplied to the subsequent vanadium extraction operation to obtain vanadium pentoxide.

[0052] The combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com