Preparation method of thin-strip continuous casting high-performance 7XXX aluminum alloy thin strip

An aluminum alloy, high-performance technology, applied in the direction of metal rolling, etc., can solve the problems that hinder the wide application, achieve the effect of shortening the processing time, hindering the recrystallization process, and refining the recrystallization grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below by embodiment and accompanying drawing, but this is not limitation of the present invention, those skilled in the art can make modification or improvement according to the basic idea of the invention, but as long as not departing from the basic idea of the present invention, all in within the scope of the present invention.

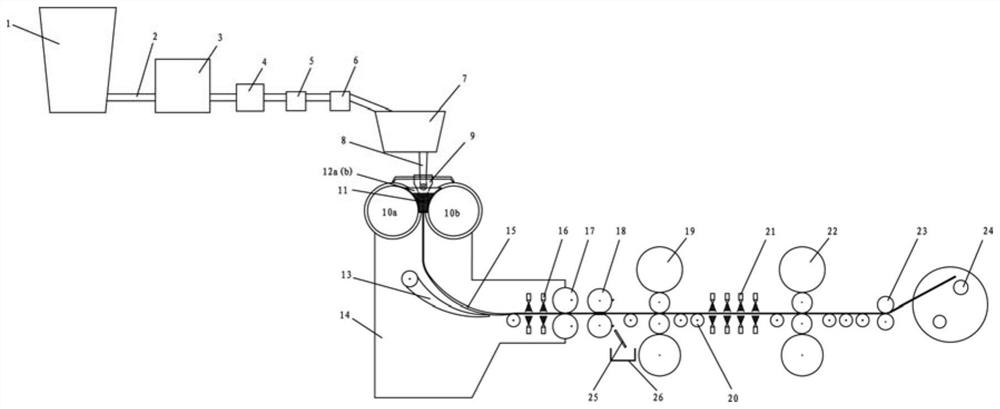

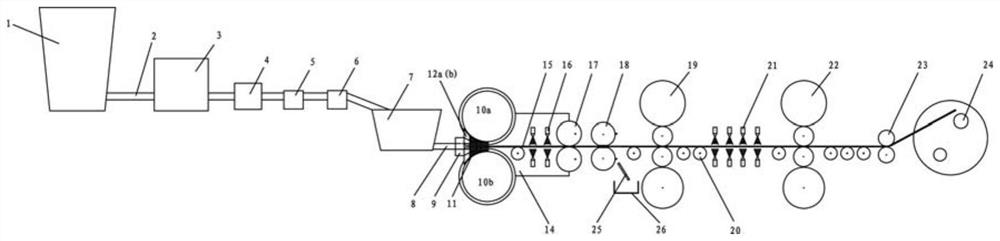

[0082] see figure 2 , Embodiment 1 of the present invention, using a vertical casting machine to prepare high-performance 7XXX aluminum alloy strips.

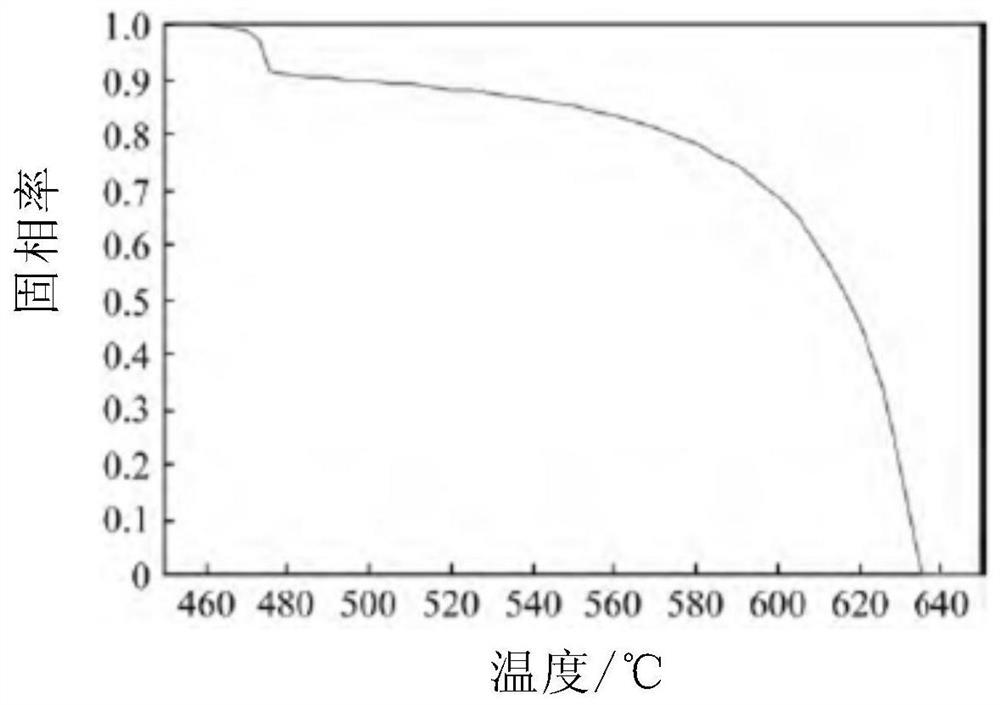

[0083] The smelted aluminum alloy liquid conforming to the design of the chemical composition of the present invention is introduced from the smelting furnace 1 through the launder 2 into the resting furnace 3 for standing. The molten aluminum alloy is transported from the static furnace 3 to the front box 4 through the launder 2, and flows into the tundish 7 after degassing 5 and filtering 6, where the aluminum alloy liquid is semi-solid t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com