Forced air cooling type laser cooling system

A cooling system and forced air cooling technology, which is applied to laser cooling devices, lasers, laser components, etc., can solve the problems of reduced thermal conductivity and heat transfer coefficient, high instantaneous power, and large calorific value, and achieve strong heat transfer capability and environmental protection The effect of adaptability, small environmental restrictions, and large heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

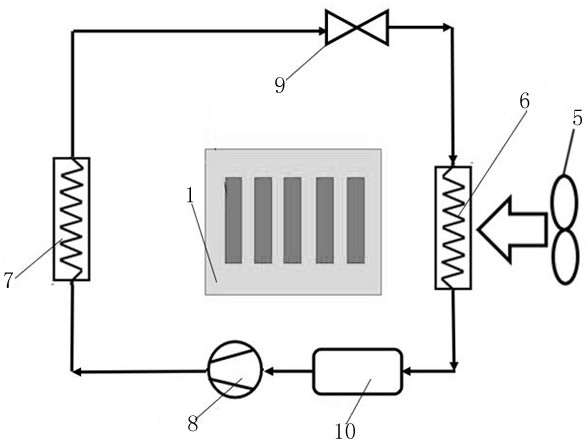

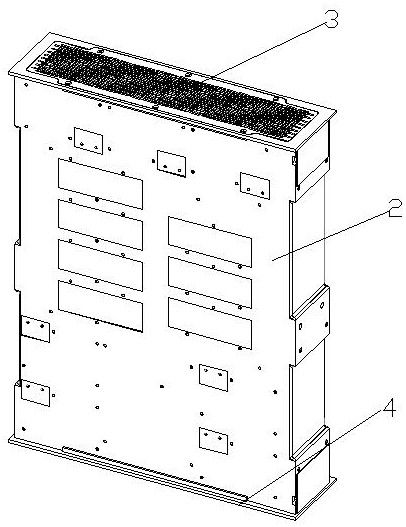

[0024] As shown in the figure, a forced air-cooled laser cooling system of the present invention includes laser heating components, the laser heating components 1 are installed in a box body 2, and an air inlet 3 is provided on one side of the box body 2 , the other side is provided with an air outlet 4, the air inlet 3 is connected with an air supply device 5, the air inlet 3 is provided with a first cooling device 6, and the first cooling device 6 is located between the air supply device 5 and the air inlet 3, the air outlet 4 is provided with a second cooling device 7.

[0025] The air is blown into the box body 2 through the air supply device 5, and the laser heating component 1 is dissipated by air cooling. At the same time, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com