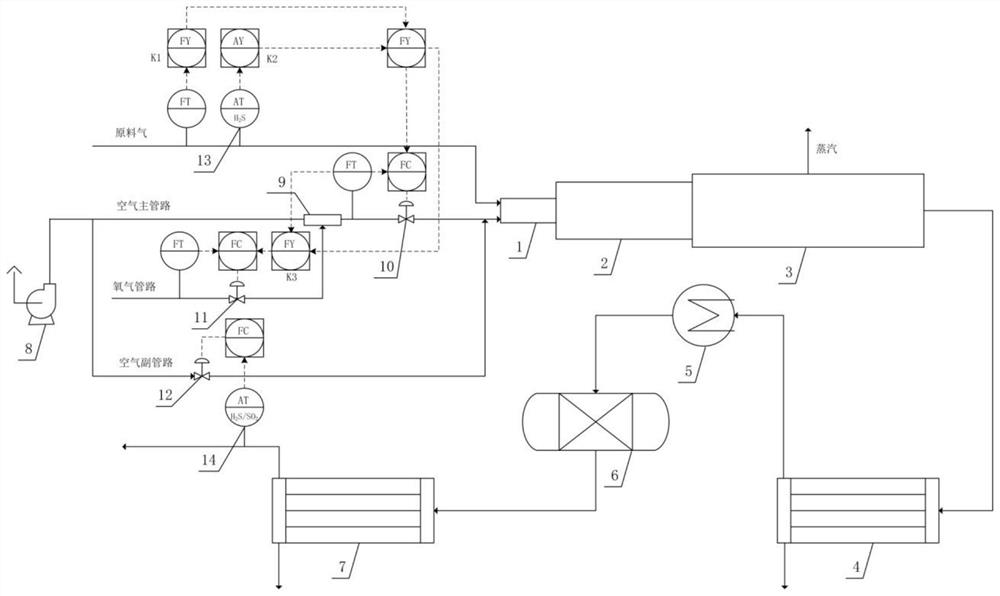

Sulfur recovery device for oxygen enrichment/air method switching in coking industry

A sulfur recovery, air method technology, applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., to achieve the effect of expanding processing capacity and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

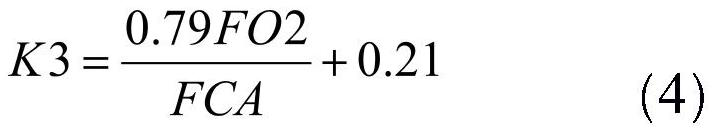

Method used

Image

Examples

Embodiment 1

[0059] Take the actual data of a 30-ton sulfur recovery unit in a coking plant in Shandong as an example:

[0060] Under the design conditions, the incoming material is the acid gas produced by the desulfurization regeneration unit, in which the molar concentration of H2S is 58.2%, and a two-stage Claus unit is used. When burning by the air method, the residence time in the main combustion furnace is 1.5s, and the temperature in the furnace is 1292°C. The conversion rate of sulfur recovery is 95.7%, and the production of sulfur meets the first-class requirements of the national standard, and the purity (quality) is as high as 99.5%.

[0061] Mode 1:

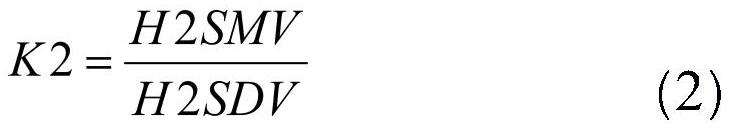

[0062] When H 2 When the molar concentration of S fluctuates between 50% and 65%, the correction coefficient K2 is 0.9 to 1.1, and the air volume of the combustion furnace is adjusted by the air method, which can satisfy the combustion temperature of the sulfur recovery reaction at 1250°C to 1350°C, and the conversion rate of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com