Method for reducing heavy metals in mineral powder

A technology of mineral powder and heavy metals, applied in non-metallic elements, chemical instruments and methods, silicon compounds, etc., can solve problems such as human harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

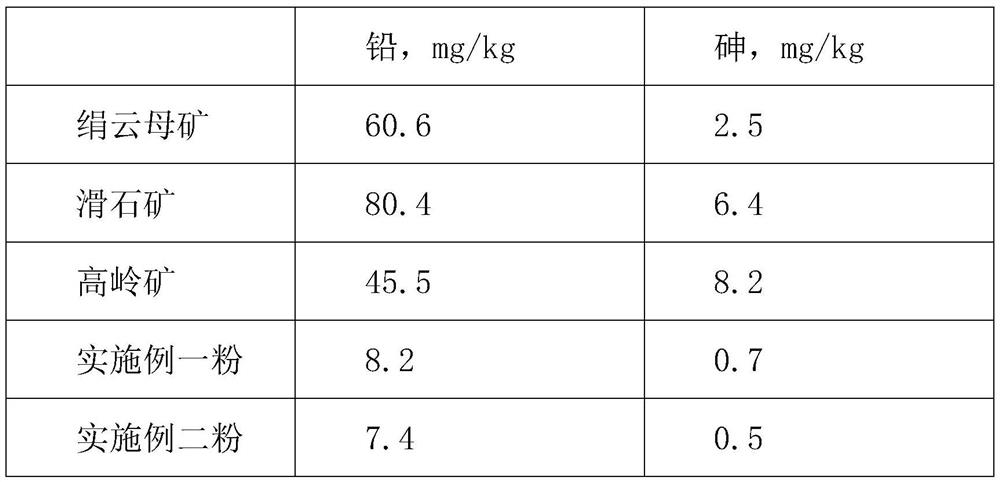

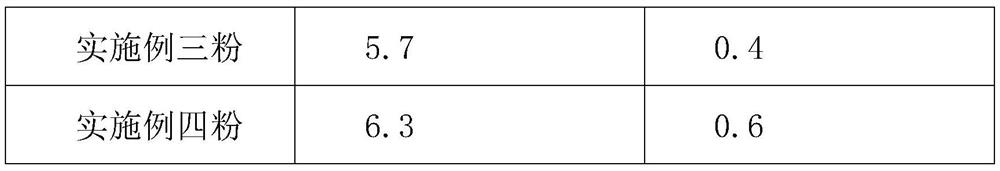

Embodiment 1

[0037] S1. Add the anthracite block into the crusher for crushing, then crush it through the crusher, sieve it through an 80-mesh sieve, and take the fine powder under the sieve for subsequent use;

[0038] S2, the sericite ore is added in the crusher for crushing, then pulverized by the crusher, sieved through an 80-mesh sieve, and the fine coal powder under the sieve is taken for subsequent use;

[0039] S3, get 70 parts of sericite powder in step S2 and 30 parts of fine coal powder in step S1 and add in pulverizer, mix evenly;

[0040] S4. Put the mixed powder in step S3 into a muffle furnace, calcinate at 600°C for 60 minutes, take it out and cool it to below 50°C;

[0041] S5. Take 1 part of sodium hexametaphosphate and add it to 99 parts of deionized water, stir and dissolve completely to prepare a dispersion;

[0042] S6. Add 30 parts of the calcined mixture in step S3 to 70 parts of the dispersion in step S4, and stir evenly.

Embodiment 2

[0047] S1. Add the anthracite block into the crusher for crushing, then crush it through the crusher, sieve it through an 80-mesh sieve, and take the fine coal powder under the sieve for subsequent use;

[0048] S2, adding the talc powder ore to the crusher for crushing, then pulverizing by the crusher, sieving through an 80-mesh sieve, and taking the fine powder under the sieve for subsequent use;

[0049] S3, take 60 parts of talcum powder in step S2 and 40 parts of fine coal powder in step S1 and add them to the pulverizer, and mix evenly;

[0050] S4. Put the mixed powder in step S3 into a muffle furnace, calcinate at 700°C for 70 minutes, take it out and cool it to below 50°C;

[0051] S5. Take 5 parts of sodium polyphosphate and add it to 95 parts of deionized water, stir and dissolve completely to prepare a dispersion;

[0052] S6. Add 30 parts of the calcined mixture in step S3 to 70 parts of the dispersion in step S4, and stir evenly;

[0053] S7, the slurry in step...

Embodiment 3

[0057] S1. Add the anthracite block into the crusher for crushing, then crush it through the crusher, sieve it through an 80-mesh sieve, and take the fine coal powder under the sieve for subsequent use;

[0058] S2, adding the kaolin ore to the crusher for crushing, then pulverizing by the crusher, sieving through an 80-mesh sieve, and taking the fine powder under the sieve for subsequent use;

[0059] S3. Take 60 parts of kaolin in step S2 and 40 parts of fine coal powder in step S1 and add them to the pulverizer, and mix evenly;

[0060] S4. Put the mixed powder in step S3 into a muffle furnace, calcinate at 800°C for 90 minutes, take it out and cool it to below 50°C;

[0061] S5. Take 5 parts of sodium polyphosphate and add it to 95 parts of deionized water, stir and dissolve completely to prepare a dispersion;

[0062] S6. Add 30 parts of the calcined mixture in step S3 to 70 parts of the dispersion in step S4, and stir evenly;

[0063] S7, the slurry in step S5 is wet-g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com