Bio-based intumescent flame-retardant composite material as well as preparation method and application thereof

An intumescent flame retardant and composite material technology, which is applied in the field of flame retardant polymer materials, can solve the problems of no intumescent flame retardant and cannot be green, and achieve the effect of less organic solvent and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

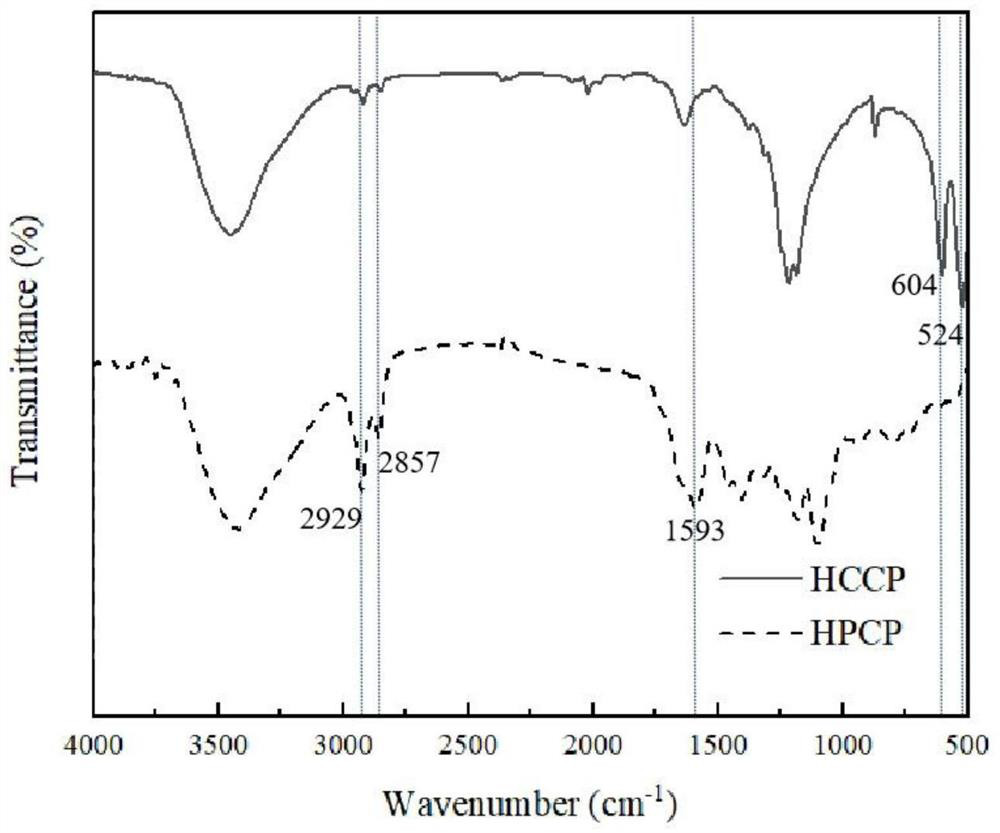

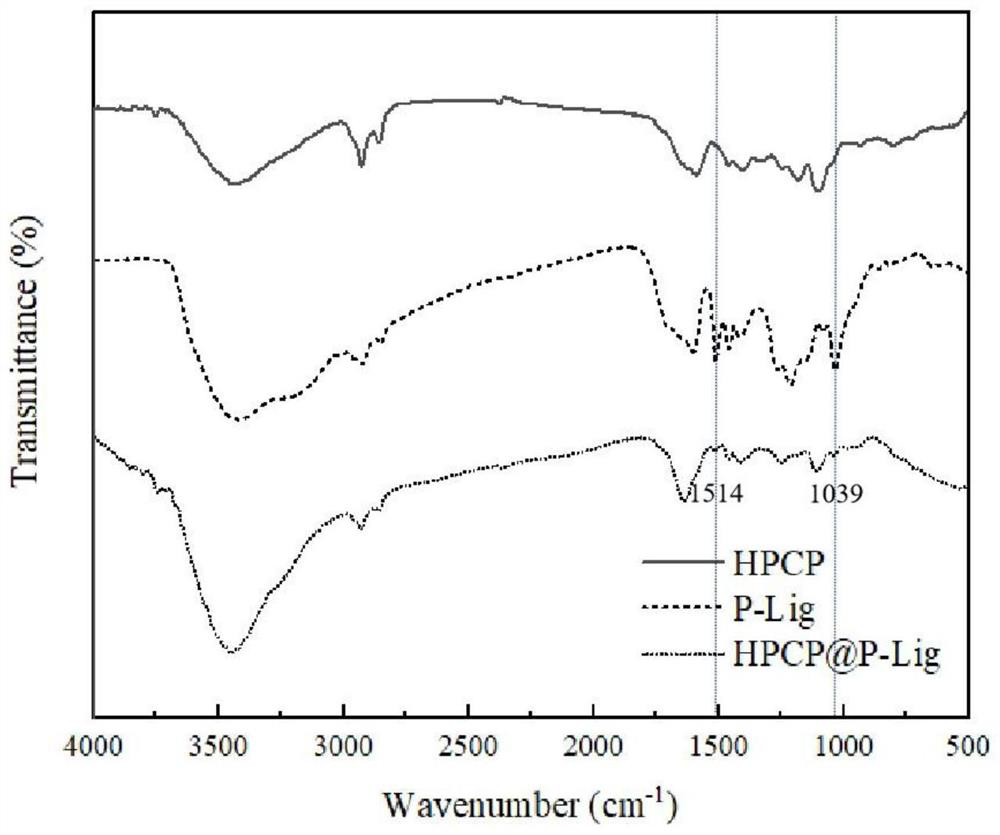

[0030] S1. Add 7.36g of pentamethylenediamine, 30mL of organic solvent dioxane, and 10g of acid-binding agent potassium carbonate into a 250mL three-necked flask, stir mechanically (rotating speed 500rpm), and then dropwise add phosphazene containing phosphazene with a concentration of 13wt% in 30mL. In a dioxane organic solvent, the reaction was stirred for 3 h under ice-bath conditions, and then the precipitate was filtered, washed three times with deionized water, and dried in a vacuum oven at 80 ° C for 12 h to obtain a white solid of pentamethylenediaminophosphazene (HPCP).

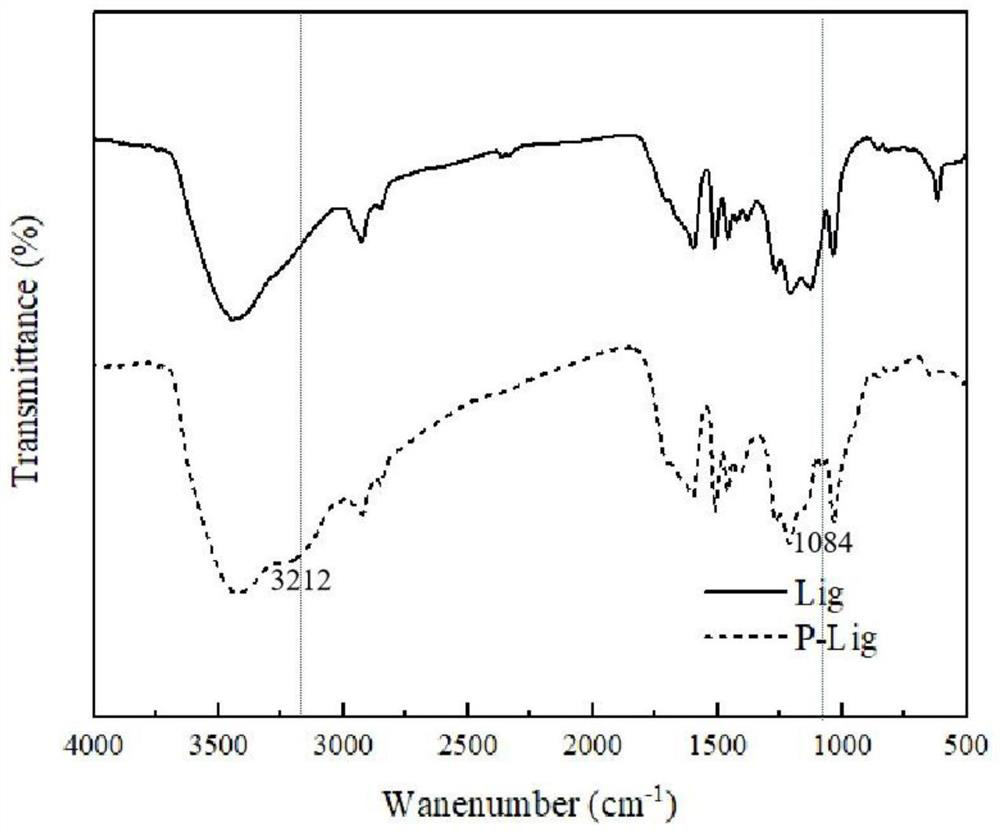

[0031] S2. Stir 2.76g of ammonium dihydrogen phosphate, 5.76g of urea, 30g of deionized water and 3.00g of lignin at 70°C for 1h, dry at 70°C, and then cure at 170°C for 1h, then use 1mol / L hydrochloric acid The solution was soaked, filtered, washed with deionized water three times, and then vacuum-dried at 80° C. for 12 hours to obtain a black solid of phosphorylated lignin (P-Lig).

[0032] S3, dis...

Embodiment 2

[0034] S1. Add 7.36g of pentamethylenediamine, 30mL of organic solvent dioxane, and 10g of acid-binding agent potassium carbonate into a 250mL three-necked flask, stir mechanically (rotating speed 500rpm), and then dropwise add phosphazene containing phosphazene with a concentration of 13wt% in 30mL. In a dioxane organic solvent, the reaction was stirred for 3 h under ice-bath conditions, and then the precipitate was filtered, washed three times with deionized water, and dried in a vacuum oven at 80 ° C for 12 h to obtain a white solid of pentamethylenediaminophosphazene (HPCP).

[0035] S2. Stir 2.76g of ammonium dihydrogen phosphate, 5.76g of urea, 30g of deionized water and 3.00g of lignin at 70°C for 1h, dry at 70°C, and then cure at 170°C for 1h, then use 1mol / L hydrochloric acid The solution was soaked, filtered, washed with deionized water three times, and then vacuum-dried at 80° C. for 12 hours to obtain a black solid of phosphorylated lignin (P-Lig).

[0036] S3, dis...

Embodiment 3

[0038] S1. Add 7.36g of pentamethylenediamine, 30mL of organic solvent dioxane, and 10g of acid-binding agent potassium carbonate into a 250mL three-necked flask, stir mechanically (rotating speed 500rpm), and then dropwise add phosphazene containing phosphazene with a concentration of 13wt% in 30mL. In a dioxane organic solvent, the reaction was stirred for 3 h under ice-bath conditions, and then the precipitate was filtered, washed three times with deionized water, and dried in a vacuum oven at 80 ° C for 12 h to obtain a white solid of pentamethylenediaminophosphazene (HPCP).

[0039] S2. Stir 2.76g of ammonium dihydrogen phosphate, 5.76g of urea, 30g of deionized water and 3.00g of lignin at 70°C for 1h, dry at 70°C, and then cure at 170°C for 1h, then use 1mol / L hydrochloric acid The solution was soaked, filtered, washed with deionized water three times, and then vacuum-dried at 80° C. for 12 hours to obtain a black solid of phosphorylated lignin (P-Lig).

[0040]S3, disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com