Structural system and process for quick replacement and maintenance of section steel expansion joints

A technology of expansion joints and section steel, which is applied in bridge maintenance, bridge parts, erection/assembly of bridges, etc., can solve the problems of reduced road traffic capacity, complex reinforcement of section steel expansion joints, manual on-site mixing, etc., to improve installation accuracy and The effect of construction quality, improvement of maintenance operation efficiency, and low-cost repair and reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

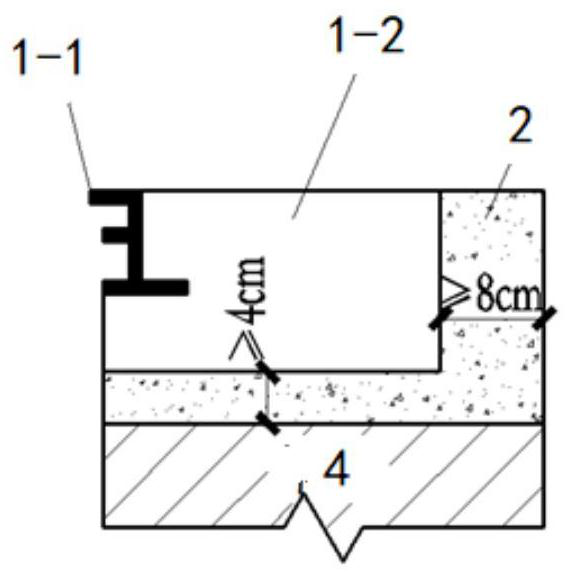

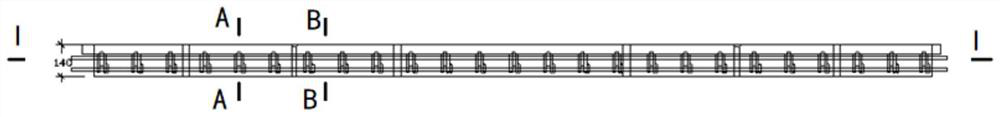

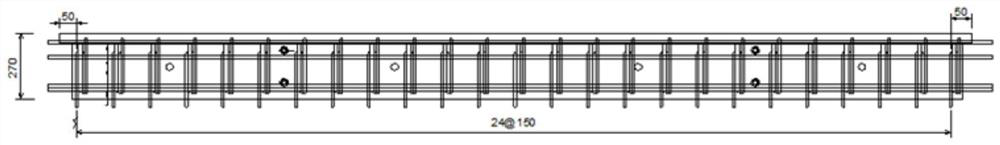

[0030] like Figure 1 to Figure 10 As shown, the structural system and technology of the rapid maintenance of the steel expansion joints of the present invention are used for the rapid maintenance of the existing steel expansion joints 3 on the beam top 4. The existing steel expansion joints 3 include expansion joint steel components 3-1 and anchoring End concrete 3-2.

[0031] First of all, the structural system for replacement and maintenance innovatively adopts the combined form of prefabricated parts 1 plus rapid UHPC concrete wet joint 2. The prefabricated part 1 is composed of a steel component 1-1 and concrete 1-2, the steel component 1-1 adopts E-shaped steel, and the concrete 1-2 adopts C50 steel fiber concrete. The prefabricated part 1 is wrapped by the wet joint 2 from 2 directions on the side, 1 direction on the front, and 1 direction on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com