GIL equipment fault joint positioning and early warning method based on vibration and voiceprint characteristic quantity extraction

A technology of equipment failure and voiceprint features, applied in the field of electric power, can solve problems such as inability to solve economic problems, achieve the effect of good GIL fault early warning and positioning functions, cost saving, and less external interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

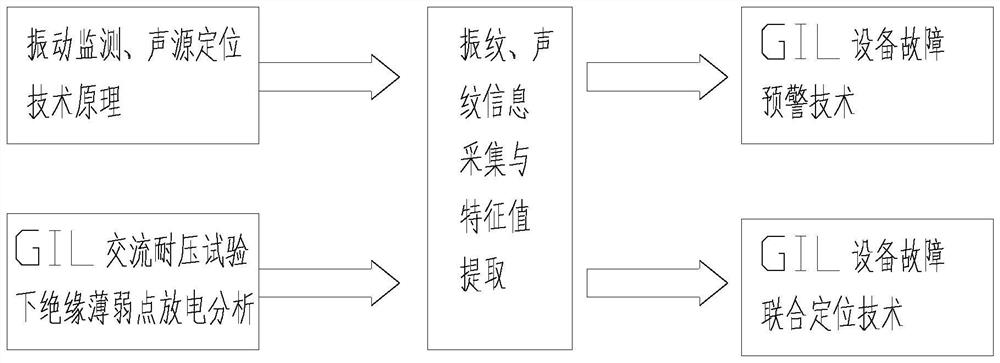

[0025] A GIL device fault combined with a vibration and sound feature amount, based on vibration spectrum and acoustic spectroscopy, extracting the vibration feature amount of GIL equipment and sound characteristics, establishing the relationship between vibration map and acoustic spectrum and The mapping relationship between GIL common faults, constructs a GIL device fault warning simulation model based on artificial intelligence algorithm, and improve the GIL device fault combined with GIL equipment extracted based on vibration and sound characteristics. In the case of periodic vibration, the vibration signal is monitored, and the acoustic array sensor captures the sound line information released when the AC pressure test, thereby performing the accurate positioning of the GIL fault.

[0026] Further, the use of effective noise suppression techniques, removing the vibration signal of the site and the background noise of the audio signal, forming a key technique for the accurate ...

Embodiment 2

[0035] A GIL device fault combined with the GIL device extracted based on vibration and sound pattern, which is different from the first embodiment: by theoretical analysis and simulation modeling, the electric field distribution of the electric field distribution of the insulation of GIL equipment. , Find out the law. The intrinsic vibration frequency (range) of the GIL structure and the feature amount of common sound sources are studied, and the vibration mechanism and sound source positioning of GIL failure are realized.

[0036] The present invention can be applied to the GIL device of each voltage level, which can perform early warning and positioning of GIL operational failures in time, ensuring the safety and stable operation of GIL equipment and the entire grid, which greatly enhances the efficiency of the shipment station inspection and improvement. The accuracy and effectiveness of device status detection, ensuring long-term security and stable operation of Qingyu DC str...

Embodiment 3

[0038] A GIL device fault combined with a vibration and sound feature amount, which is different from Example 1: Based on the vibration map and acoustic spectrum, extract the vibration feature amount and sound characteristic amount of GIL equipment, establish vibration. The correlation between the map and acoustic spectrum and the mapping relationship between the common fault of GIL, constructs a GIL device fault early warning simulation model based on artificial intelligence algorithm, and improve the GIL equipment fault combined with the vibration and sound feature amount.

[0039] It will greatly improve the efficiency of the shipment inspection efficiency, crack the insufficient scene of the site, promote the safety of the power grid, economic operation, which is conducive to the safety of national energy delivery. Helping the national security of the national strategic Qingyu DC project, enhance the efficiency of equipment operation, help to improve the social image of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com