Preparation method of high-compaction lithium iron phosphate pole piece

A technology of solid lithium iron phosphate and lithium iron phosphate is applied in the field of preparation of high-pressure solid lithium iron phosphate pole pieces, which can solve the problems of cumbersome process, decreased cycle life, and inability of electrolyte to infiltrate pole pieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method for high-pressure lithium iron phosphate pole piece, as follows:

[0026] 1. Material preparation:

[0027] 1) Nano-sized initial raw materials

[0028] First, 5Kg of lithium carbonate, ferrous sulfate, ammonium dihydrogen phosphate and glucose were wet ball milled for 25 hours to make the average particle size reach 200-500nm, and the obtained nano-scale initial raw material was marked as C, and dried for later use;

[0029] 2) Raw material preprocessing:

[0030] The nanoscale initial raw material C is compacted under the pressure of 1.5MPa and 6MPa respectively, which are respectively marked as A and B; then,

[0031] 3) Put A, B, and C raw materials in a tube furnace respectively, and perform pretreatment at 350°C to obtain pretreated A, B, and C materials as precursors.

Embodiment 1

[0033] A lithium iron phosphate pole piece to be compacted at high pressure, prepared according to the following steps:

[0034] 1) to 3) steps as above;

[0035] 4) Precursor mixing treatment: Take the pretreated A and C materials obtained in step 3) and take the same mass, grind and mix them, put them in a tube furnace, and sinter them at 720°C for 5.5 hours to obtain highly dense iron phosphate Lithium cathode material, marked as A+C;

[0036] 5) Pole sheet preparation: mix the highly dense active material lithium iron phosphate cathode material A+C, the conductive agent and the binder at a mass ratio of 95:3.5:1.5, and prepare the slurry; apply the slurry to a fixed thickness On the aluminum foil, a high-pressure positive electrode sheet with particle size classification and mixed filling of large and small particles is obtained. The thickness is 75 μm. The material is made into an electrode sheet, and the compaction density can reach 2.52g / cm 3 .

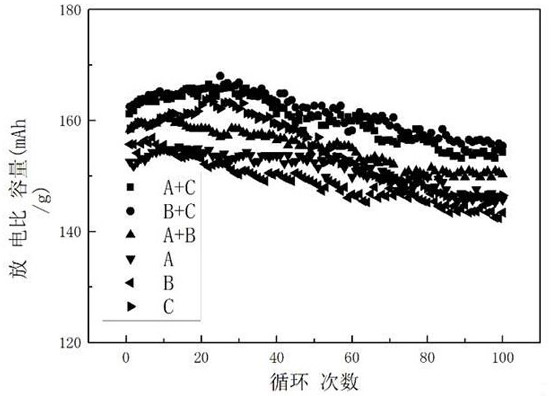

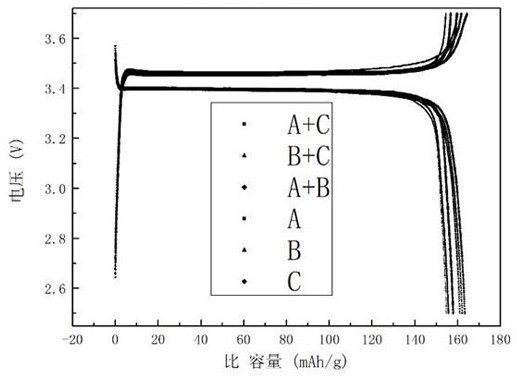

[0037] The performan...

Embodiment 2

[0039] A lithium iron phosphate pole piece to be compacted at high pressure, prepared according to the following steps:

[0040] 1) to 3) steps as above;

[0041] 4) Precursor mixing treatment: Take pretreated B and C of equal mass for grinding and mixing, place them in a tube furnace, and sinter at a high temperature of 720°C for 5.5 hours to obtain a highly dense lithium iron phosphate cathode material, marked as B +C;

[0042] 5) Pole sheet preparation: mix the highly dense active material lithium iron phosphate cathode material active material B+C, conductive agent and binder at a mass ratio of 95:3.5:1.5, and mix the slurry; coat the slurry with a fixed thickness On the aluminum foil, a highly compacted positive pole piece is obtained, the thickness of which is 75um, and the compacted density of the pole piece can reach 2.67g / cm 3 .

[0043] The performance test results of the lithium iron phosphate pole piece obtained in this embodiment are shown in Table 1. The spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com