A kind of tpu composite glue, protective film and preparation method thereof

A protective film and glue technology, applied in the field of optical film, can solve the problems of low hardness and modulus, which cannot meet the demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

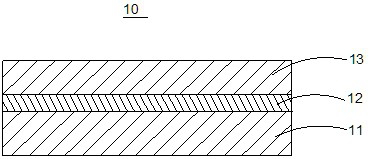

[0055] In the third aspect, the present application example provides a method for preparing the protective film 10 provided in the second aspect, which includes:

[0056] Apply the TPU composite glue to one surface of the second release film 13, dry and solidify to obtain the TPU adhesive layer 12; attach the first release film 11 to the side of the TPU adhesive layer 12 away from the second release film 13 On one side, aging treatment is performed to obtain the protective film 10 .

[0057] Since the release force of the first release film 11 is greater than that of the second release film 13, the second release film 13 is not easy to remove during actual use, so the TPU composite glue is applied to the second release film. One surface of the film 13 forms a TPU adhesive layer 12, and then attaches the first release film 11. This arrangement allows the first release film 11 to effectively protect the TPU adhesive layer 12, preventing the TPU adhesive layer 12 from being far a...

Embodiment 1

[0062] The protective film includes a first release film, a TPU adhesive layer and a second release film laminated in sequence. The release force of the first release film was 35 g / mm, and the release force of the second release film was 15 g / mm.

[0063] Wherein, protective film is made by following preparation method:

[0064] (1) Obtain TPU composite glue:

[0065] 100 parts by weight of aliphatic polyurethane acrylic resin (AA4835 of Eurasia Enterprise Co., Ltd.), 15 parts by weight of TPU particles (5715 of Lubrizol), and 90 parts by weight of ketone-aldehyde resin (KR of Anfeng Industrial Co., Ltd. -1021), 28 parts by weight of methyl ethyl ketone, 52 parts by weight of cyclohexanone, 0.4 parts by weight of polyester-modified hydroxyl-functional polydimethylsiloxane solution (Byk Chemicals, BYK-371), 15 parts by weight 2 parts of high-functionality HDI trimer (Covestro, aliphatic polyisocyanate series, N3700) were mixed to obtain TPU composite glue.

[0066] (2) Coat ...

Embodiment 2

[0069] Its difference with embodiment 1 only lies in:

[0070] The protective film includes a first release film, a TPU adhesive layer and a second release film laminated in sequence. The release force of the first release film was 46 g / mm, and the release force of the second release film was 16 g / mm.

[0071] Wherein, protective film is made by following preparation method:

[0072] (1) Obtain TPU composite glue:

[0073]60 parts by weight of aliphatic polyurethane acrylic resin (AA4835 of Eurasia Enterprise Co., Ltd.), 20 parts by weight of TPU particles (5715 of Lubrizol), and 70 parts by weight of ketone-formaldehyde resin (An Feng Industrial Co., Ltd. KR -1021), 32 parts by weight of methyl ethyl ketone, 47 parts by weight of cyclohexanone, 0.6 parts by weight of polyester-modified polydimethylsiloxane solution containing hydroxyl functional groups (BK, BYK-371), 10 Mix parts by weight of high-functionality HDI trimer (Covestro, aliphatic polyisocyanate series, N3700) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com