Colored paint UVC curing process

A curing process and color paint technology, applied in the direction of surface pretreatment, device for coating liquid on the surface, coating, etc., can solve the problems of yellowing of paint surface, large energy loss, high curing cost, and achieve yellowing of paint surface The effect of less image, higher energy ratio and slower rise rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

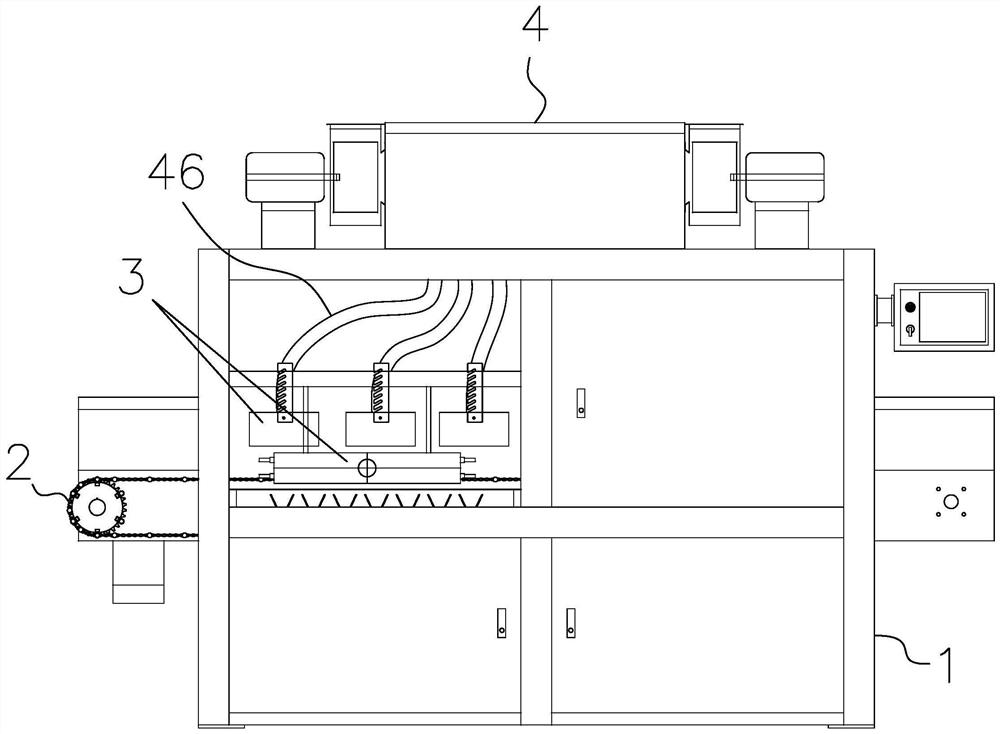

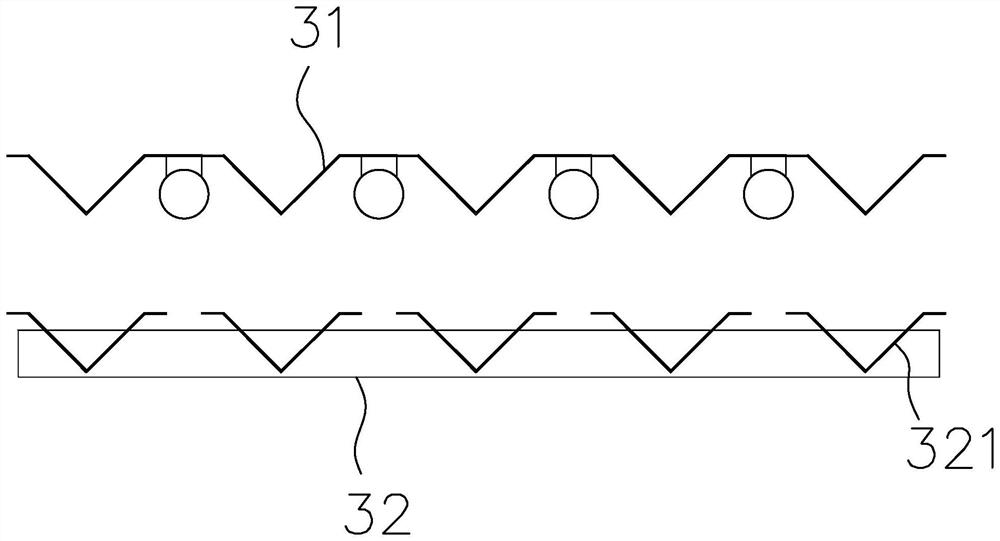

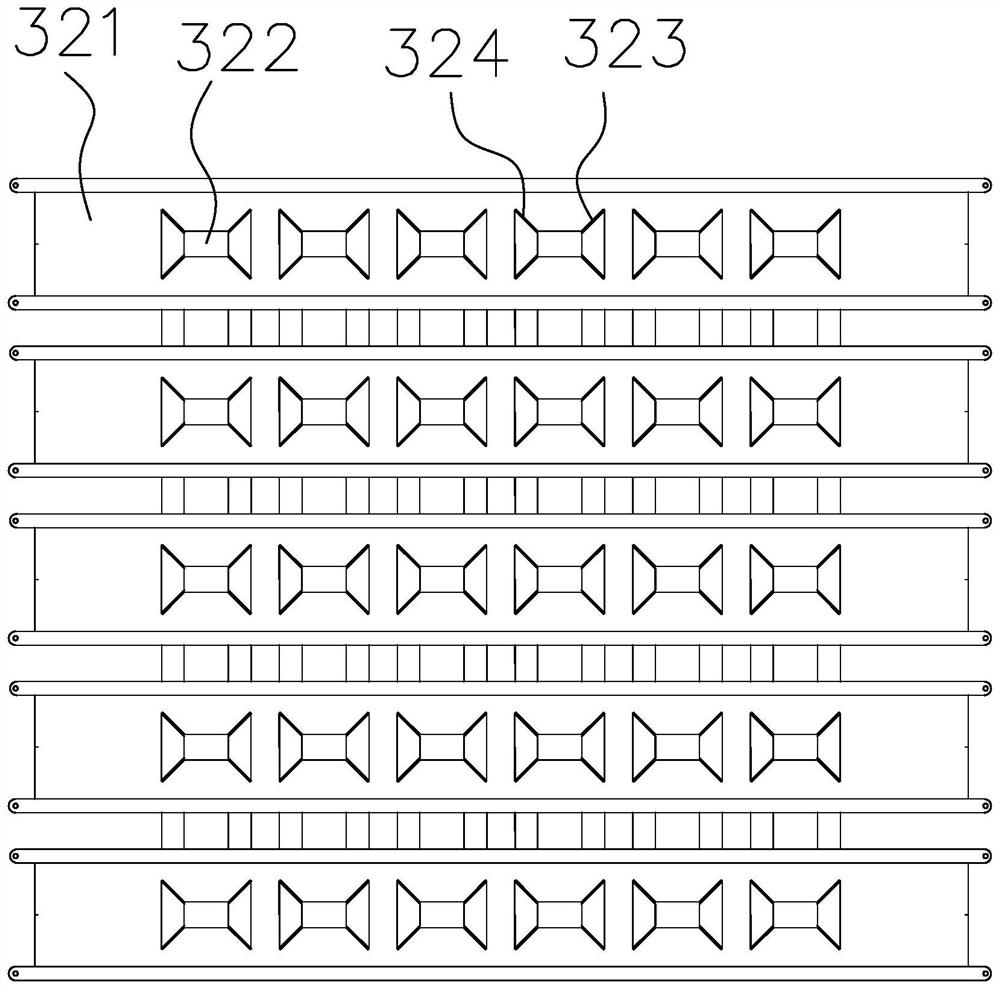

[0027] Such as Figure 1 to Figure 5 As shown, the present embodiment discloses a UVC curing process for color paint, which is automatically cured by curing equipment. The curing equipment includes a cabinet 1, a product delivery roller 2 for transporting painted workpieces into the curing equipment for ultraviolet curing, and for emitting ultraviolet rays to the curing equipment. The UV light source group 3 for curing the paint surface of the painted workpiece, the UV light source group 3 includes a UVC light source and a UVA light source, the paint surface of the painted workpiece is jointly cured by the UVC light source and the UVA light source, and the ultraviolet wavelength of the UVC light source is In the range of 250-260nm; the ultraviolet wavelength of the UVA light source is in the range of 395-420nm. The color paint curing process of the present invention adopts the joint curing method of UVC light source and UVA light source to cure the color paint. Compared with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com