A kind of UV photocuring coating for aluminum-based copper-clad laminates

A technology of light-curing coatings and aluminum-based copper-clad laminates, applied in polyester coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as corrosion of aluminum-based copper-clad laminates, achieve fast curing speed, good adhesion, and complete curing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

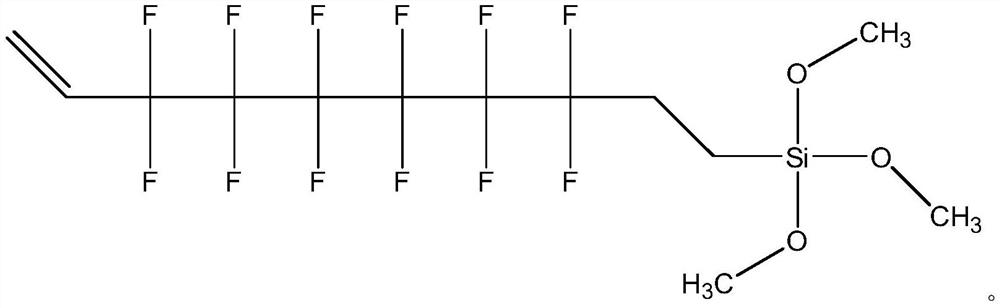

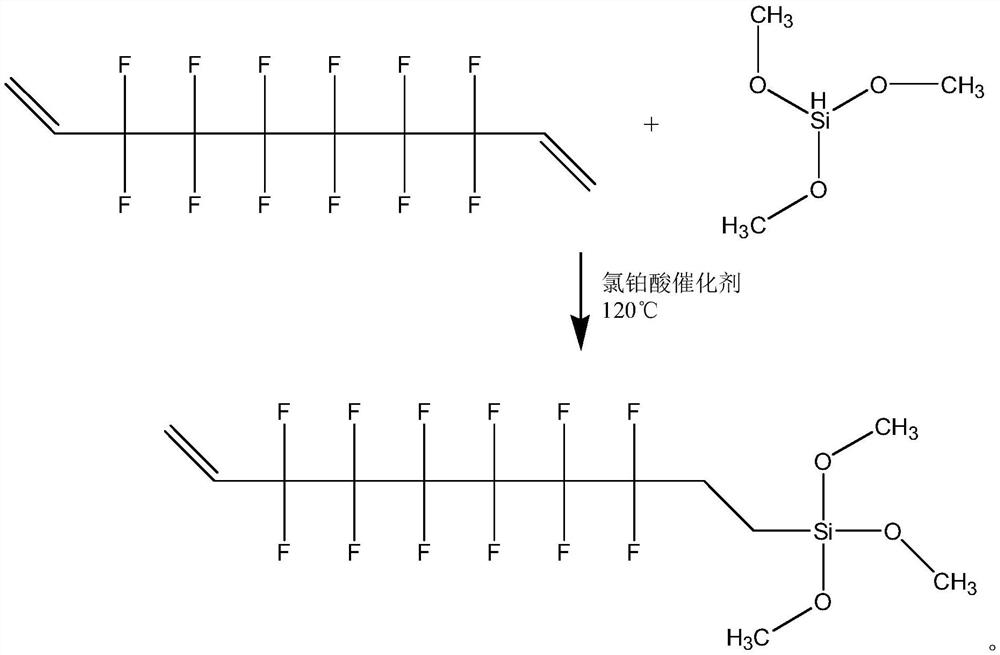

Method used

Image

Examples

Embodiment Construction

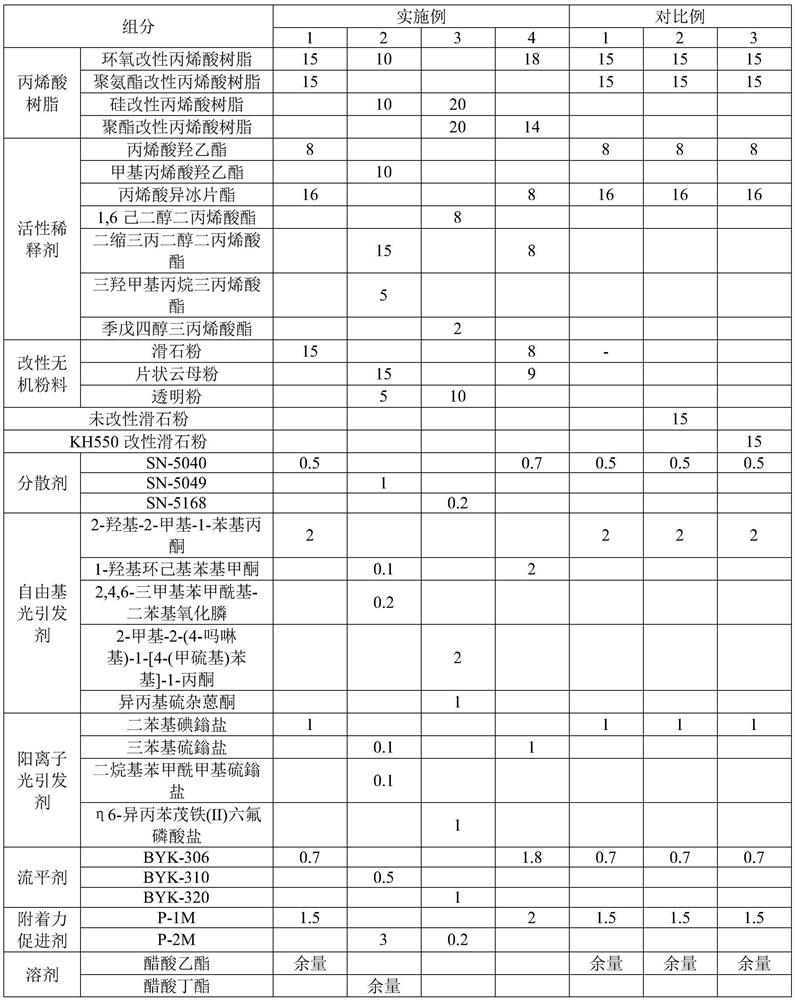

[0032] The present invention is described in further detail now in conjunction with embodiment.

[0033] The preparation method of modified inorganic powder is:

[0034] Prepare ethanol aqueous solution according to the volume ratio of ethanol to water 8:1, adjust the pH value to 8-9, then add a modifier accounting for 20% of the mass percentage of ethanol aqueous solution, stir evenly, then add inorganic powder, and stir at 40-50°C 10-30min, filter, wash, and dry to obtain modified inorganic powder, wherein the mass ratio of modifier to inorganic powder is 1:15-20.

[0035] The preparation method of UV photocuring coating is: weigh each component in proportion, under the condition of avoiding light, mix acrylic resin, reactive diluent, dispersant, leveling agent, adhesion promoter and photoinitiator at a speed of 1500 rpm Mix evenly, then add modified inorganic powder to fully disperse evenly, then add solvent to disperse evenly.

[0036] See Table 1 for the dosage of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com