Production process of antibacterial composite fabric and antibacterial composite fabric

A composite fabric and production process technology, applied in the field of fabric production, can solve the problems of skin pollution and the inability of antibacterial fabrics to carry fragrance and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

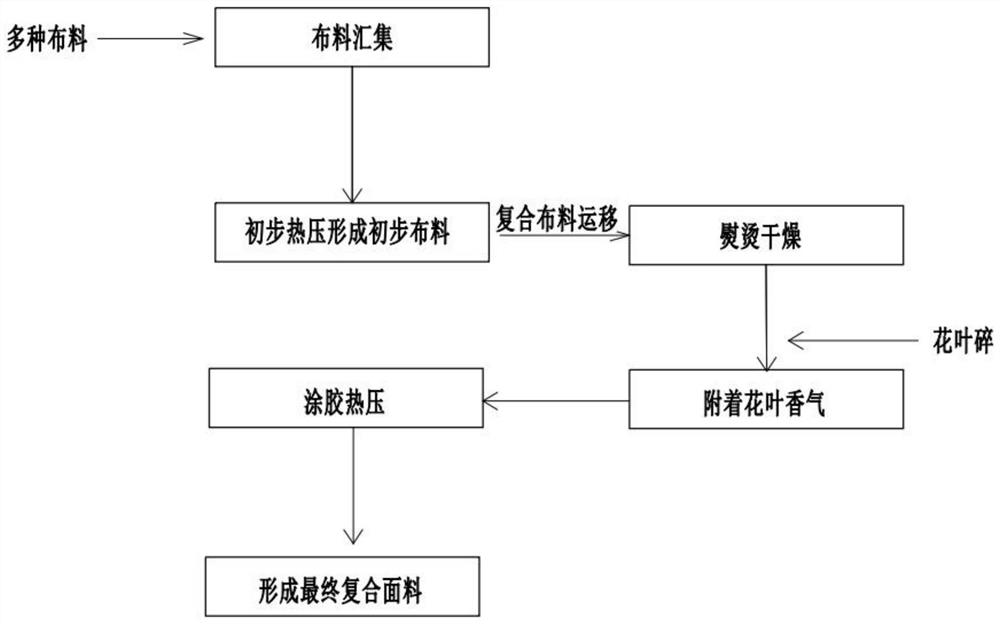

[0023] The production process of the antibacterial composite fabric can refer to figure 1 Get an example working process:

[0024] A production process of antibacterial composite fabric, the process includes the following steps: Step 1: Prepare silver ion antibacterial fabric, cotton fabric and acrylic fiber fabric, move them synchronously according to the order from bottom to top, and move them up and down on the cotton fabric during the process of moving the cotton fabric The surface carries TPU hot melt adhesive film to move together; Step 2: When the silver ion antibacterial fabric and cotton fabric and acrylic fabric are collected, perform hot pressing treatment to form a preliminary composite fabric. The hot pressing treatment temperature is 220 ° C, and the hot pressing time is 5 minutes; Step 3: Perform a hot bath on the preliminary composite fabric under the steam of flower leaves. The steam temperature of the hot bath is 150°C, the hot bath time is 2 minutes, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com