Wastewater treatment zero-emission method of household garbage incineration power plant

A technology for domestic waste incineration and wastewater treatment, applied in heating water/sewage treatment, water/sludge/sewage treatment, special treatment targets, etc. and other problems, to achieve the effect of saving primary energy conversion, improving heat utilization, and reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing:

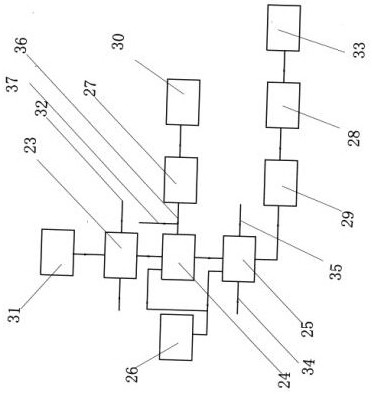

[0026]A waste water treatment zero-discharge system of a domestic waste incineration power plant, comprising an air-water indirect heat exchanger 23, a flash tank 24, a condensation tank 25, a vacuum pump 26, a first booster pump 27, a condensate tank 28, a second The precipitation waste water 31 produced in the booster pump 29, the garbage incinerator 30 and the air-water direct contact heat exchanger, the water side input end of the air-water indirect heat exchanger 23 flows into the air-water direct contact heat exchanger Produced sedimentation wastewater 31, the water side output end of the air-water indirect heat exchanger 23 is connected with the water input end of the flash tank 24, and the gas side input end of the air-water indirect heat exchanger 23 is connected with the garbage The flue gas processed by the flue gas purification system output by the incinerator 30 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com