Preparation method and application of universal double-layer hydrogel driver

A hydrogel driver, a universal technology, applied in the field of preparation of universal double-layer hydrogel driver, can solve the problems of poor universality and achieve the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step (1), preparation of hydrogel pre-polymerization solution: add 0.0762g XLG type synthetic magnesium lithium silicate to 10mL deionized water and magnetically stir for 4h until completely dispersed to obtain a suspension, meanwhile add 0.226g 1-hydroxycyclohexyl Add phenyl ketone to 10mL of methanol to prepare an initiator solution, then add 1.13g of monomeric N-isopropylacrylamide and 0.1mL of the initiator solution to the suspension in sequence, stir for 2 hours at room temperature in the dark, and finally pour into the solution Bubble high-purity nitrogen gas to remove the dissolved oxygen contained in the solution to obtain a transparent (N-isopropylacrylamide)-clay hydrogel prepolymer solution;

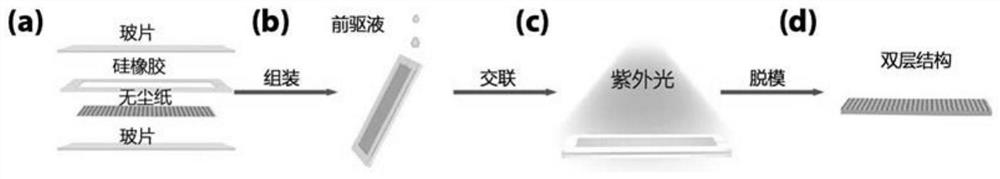

[0030] Step (2), the preparation of mold: as figure 1 As shown, the dust-free paper with a size of 40mm×10mm and a surface stripe of 90° (the angle between the stripe and the long side) and a silicone rubber gasket with a hollowed out area of 40mm×10mm were placed on ...

Embodiment 2

[0034] Step (1), preparation of hydrogel prepolymerization solution: add 0.2285g XLG type synthetic magnesium lithium silicate to 10mL deionized water and magnetically stir for 4h until completely dispersed to obtain a suspension, and at the same time add 0.226g 1-hydroxycyclohexyl Add phenyl ketone to 10mL of methanol to prepare an initiator solution, then add 1.13g of monomeric N-isopropylacrylamide and 0.1mL of the initiator solution to the suspension in sequence, stir for 2 hours at room temperature in the dark, and finally pour into the solution Bubble high-purity nitrogen gas to remove the dissolved oxygen contained in the solution to obtain a transparent (N-isopropylacrylamide)-clay hydrogel prepolymer solution;

[0035] Step (2), the preparation of mold: as figure 1 As shown, the dust-free paper with a size of 40mm×10mm and a surface stripe of 90° (the angle between the stripe and the long side) and a silicone rubber gasket with a hollowed out area of 40mm×10mm were ...

Embodiment 3

[0039] Step (1), preparation of hydrogel pre-polymerization solution: add 0.3808g XLG type synthetic magnesium lithium silicate to 10mL deionized water and magnetically stir for 4h until completely dispersed to obtain a suspension, and at the same time add 0.226g 1-hydroxycyclohexyl Add phenyl ketone to 10mL of methanol to prepare an initiator solution, then add 1.13g of monomeric N-isopropylacrylamide and 0.1mL of the initiator solution to the suspension in sequence, stir for 2 hours at room temperature in the dark, and finally pour into the solution Bubble high-purity nitrogen gas to remove the dissolved oxygen contained in the solution to obtain a transparent (N-isopropylacrylamide)-clay hydrogel prepolymer solution;

[0040] Step (2), the preparation of mold: as figure 1 As shown, the dust-free paper with a size of 40mm×10mm and a surface stripe of 90° (the angle between the stripe and the long side) and a silicone rubber gasket with a hollowed out area of 40mm×10mm were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com