Preparation method of antibacterial nanofiber membrane

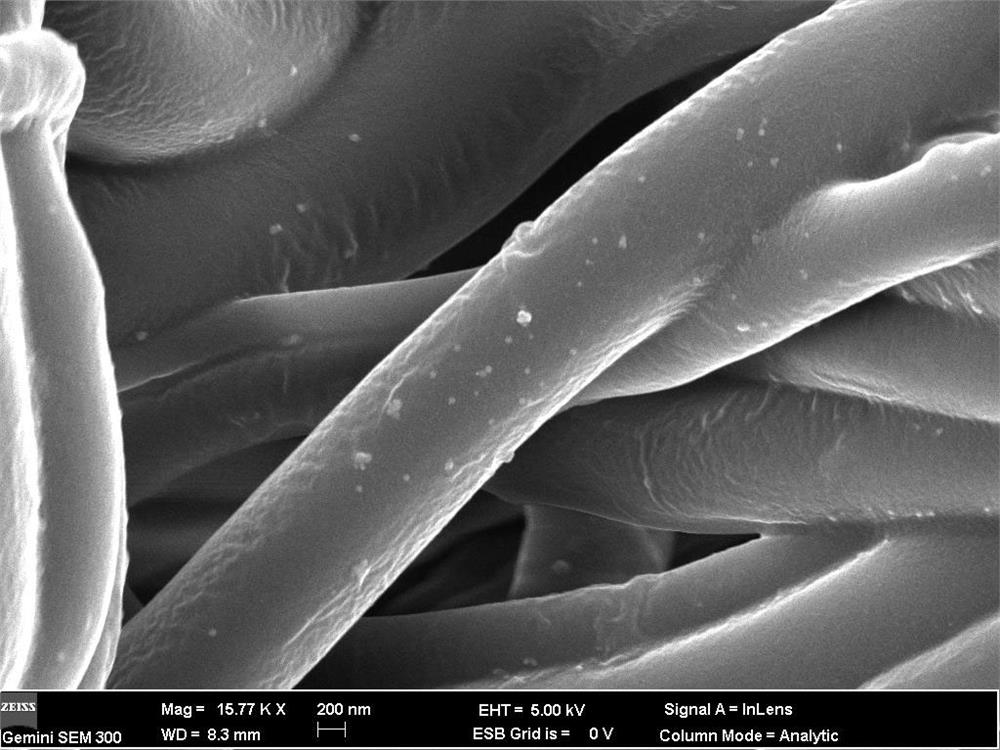

A nanofiber film and solution technology, applied in the fields of fiber chemical characteristics, rayon manufacturing, non-woven fabrics, etc., can solve the problems of poor decontamination resistance of antibacterial textiles, uneven distribution of nano-silver in the nanofiber film, etc., and achieve excellent Long-acting antibacterial performance, uniform distribution, excellent decontamination resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment provides a kind of preparation method of antibacterial nanofiber membrane, described method comprises the following steps:

[0038] (1) Prepare a silver nitrate solution with a concentration of 7g / L, add an appropriate amount of ammonia water, and stir magnetically for 1 hour to obtain a silver ammonia solution.

[0039] (2) Add the silver ammonia solution obtained in step (1) into the aqueous polyurethane emulsion with a solid content of 30%, and stir magnetically for 2 hours to obtain an aqueous polyurethane emulsion containing silver diammine hydroxide.

[0040] (3) Prepare a TPU solution with a solute mass fraction of 25%, the solvent used is DMF and acetone (volume ratio 1:1), heat and dissolve in a water bath at 60°C, and stir magnetically for 5 hours to obtain a TPU solution.

[0041] (4) Add the water-based polyurethane emulsion containing diammine silver hydroxide obtained in step (2) dropwise to the TPU solution obtained in step (3), and...

Embodiment 2

[0045] The present embodiment provides a kind of preparation method of antibacterial nanofiber membrane, described method comprises the following steps:

[0046] (1) Prepare a silver nitrate solution with a concentration of 8 g / L, add an appropriate amount of ammonia water, and stir magnetically for 1.5 hours to obtain a silver ammonia solution.

[0047] (2) Add the silver-ammonia solution obtained in step (1) into the aqueous polyurethane emulsion with a solid content of 32%, and magnetically stir for 2.5 hours to obtain an aqueous polyurethane emulsion containing silver diammine hydroxide.

[0048] (3) Prepare a TPU solution with a solute mass fraction of 27%. The solvent used is DMF and acetone (volume ratio 1:1), heated and dissolved in a water bath at 70°C, and magnetically stirred for 4 hours to obtain a TPU solution.

[0049] (4) Add the water-based polyurethane emulsion containing diammine silver hydroxide obtained in step (2) dropwise to the TPU solution obtained in s...

Embodiment 3

[0053] The present embodiment provides a kind of preparation method of antibacterial nanofiber membrane, described method comprises the following steps:

[0054] (1) Prepare a silver nitrate solution with a concentration of 9g / L, add an appropriate amount of ammonia water, and stir magnetically for 2 hours to obtain a silver ammonia solution.

[0055] (2) Add the silver ammonia solution obtained in step (1) into the aqueous polyurethane emulsion with a solid content of 35%, and stir magnetically for 3 hours to obtain an aqueous polyurethane emulsion containing silver diammine hydroxide.

[0056] (3) Prepare a TPU solution with a solute mass fraction of 30%. The solvent used is DMF and acetone (volume ratio 1:1), heated and dissolved in a water bath at 80°C, and magnetically stirred for 3 hours to obtain a TPU solution.

[0057] (4) Add the water-based polyurethane emulsion containing diammine silver hydroxide obtained in step (2) dropwise to the TPU solution obtained in step (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com