Circulating oil removal method for cobalt chloride solution

A technology of cobalt chloride and solution, applied in the field of circulating oil removal of cobalt chloride solution, can solve the problems of difficult operation of activated carbon and fiber ball regeneration, unstable oil removal rate, difficult to meet high requirements, etc., and improve the oil removal rate. The effect of oil removal stability, lifting effect, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

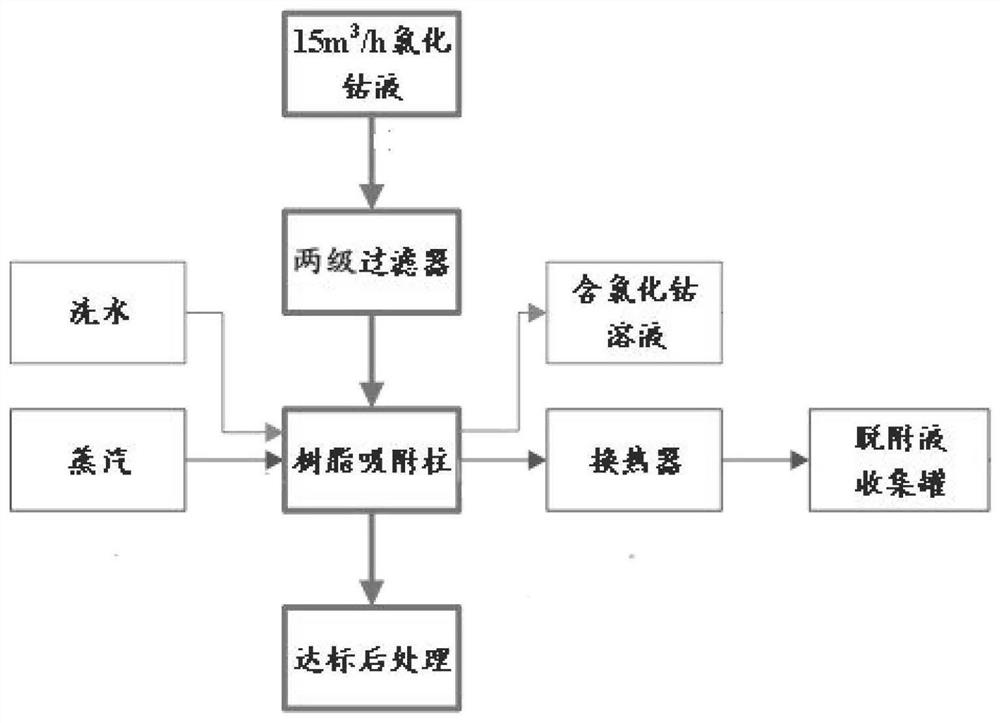

[0043] In this embodiment 1, if figure 1 As shown, after the cobalt chloride solution is lifted by the pump, it is 3 The flow rate per hour passes through a cloth bag filter with a filtration precision of 5 μm and a white ball filter with a filtration precision of 3 μm for two-stage filtration; the filtered cobalt chloride solution is sent to a resin adsorption column equipped with a TOC removal resin, and then chlorinated The TOC in the cobalt solution is adsorbed by the resin to obtain the cobalt chloride solution after removing the TOC; after the resin is saturated, the residual cobalt chloride solution in the resin adsorption column is first compressed to the cobalt chloride stock solution tank, and then 12m 3 The pure water with a conductivity of less than 200 μS / cm washes the resin adsorption column to wash out the residual cobalt chloride on the surface of the resin.

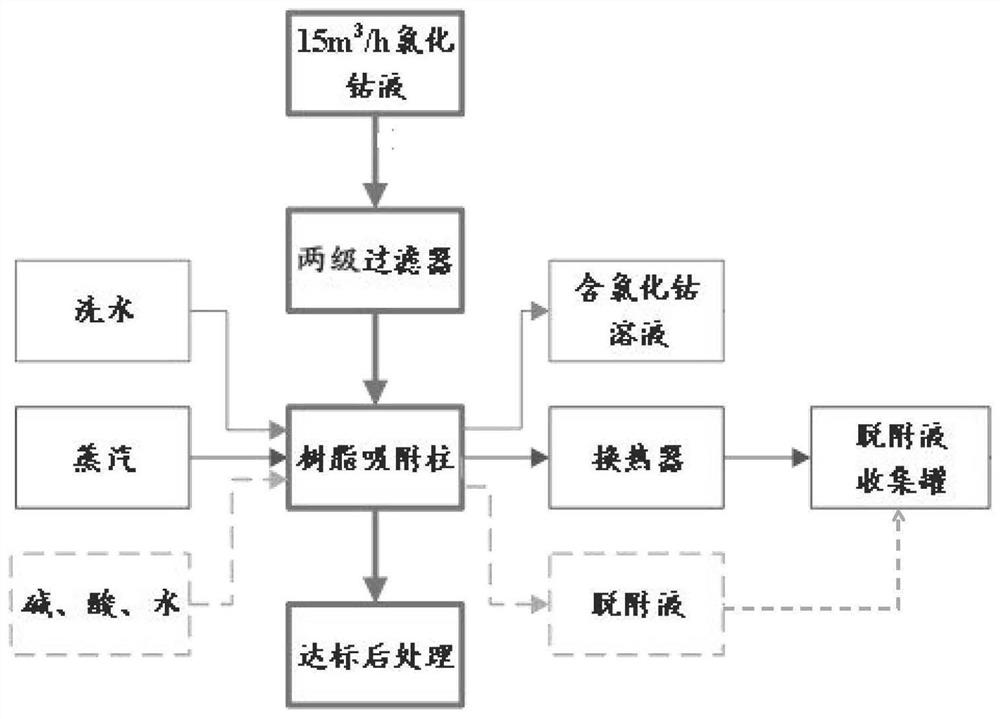

[0044] Blow off: After washing with water, feed steam, control the temperature at 120°C, and blow off...

Embodiment 2

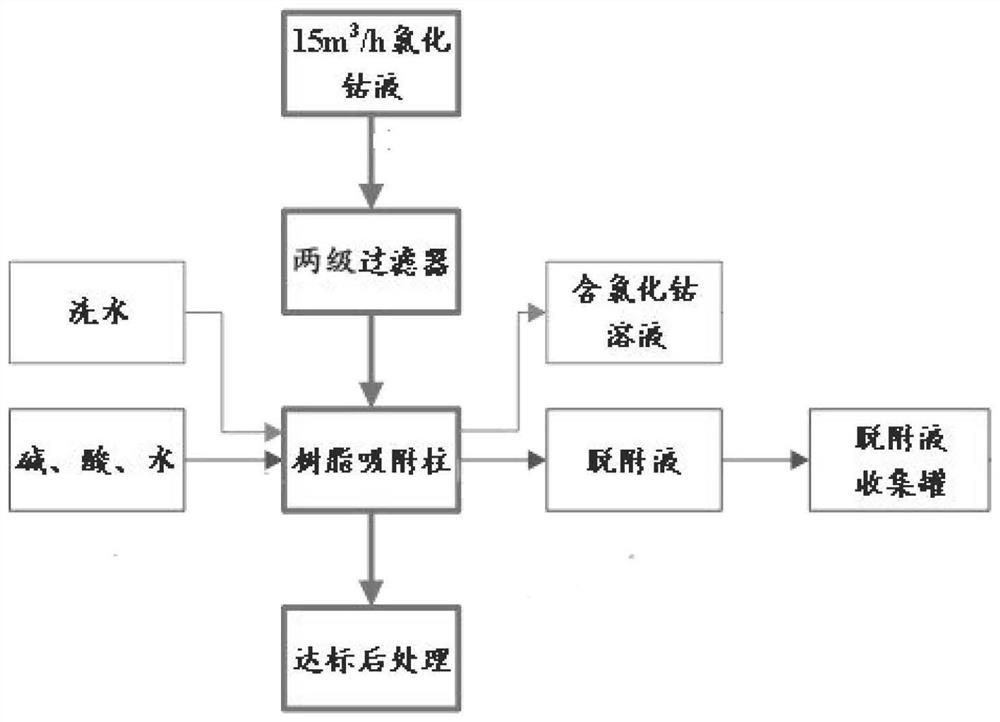

[0048] After the cobalt chloride solution is lifted by the pump, the 3 The flow rate per hour passes through a cloth bag filter with a filtration precision of 5 μm and a white ball filter with a filtration precision of 3 μm for two-stage filtration; the filtered cobalt chloride solution is sent to a resin adsorption column equipped with a TOC removal resin, and then chlorinated The TOC in the cobalt solution is adsorbed by the resin to obtain the cobalt chloride solution after removing the TOC; after the resin is saturated, the residual cobalt chloride solution in the resin adsorption column is first compressed to the cobalt chloride stock solution tank, and then the 18m 3 The pure water with a conductivity of less than 200 μS / cm washes the resin adsorption column to wash out the residual cobalt chloride on the surface of the resin.

[0049] Blow off: After washing with water, feed steam, control the temperature at 135°C, and blow off the resin adsorption column. The blow off ...

Embodiment 3

[0053] After the cobalt chloride solution is lifted by the pump, the 3The flow rate per hour passes through a cloth bag filter with a filtration precision of 5 μm and a white ball filter with a filtration precision of 3 μm for two-stage filtration; the filtered cobalt chloride solution is sent to a resin adsorption column equipped with a TOC removal resin, and then chlorinated The TOC in the cobalt solution is adsorbed by the resin to obtain the cobalt chloride solution after removing the TOC; after the resin is saturated, the residual cobalt chloride solution in the resin adsorption column is first compressed to the cobalt chloride stock solution tank, and then the 24m 3 The pure water with a conductivity of less than 200 μS / cm washes the resin adsorption column to wash out the residual cobalt chloride on the surface of the resin.

[0054] Blow off: After washing with water, feed steam, control the temperature at 150°C, and blow off the resin adsorption column. The blow off t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com