Method and device for preparing high-purity silicon monoxide in batches

A silicon monoxide and silicon dioxide technology, which is applied in the directions of silicon oxide, silicon dioxide, chemical instruments and methods, can solve the problems such as being unsuitable for large-scale industrial production, affecting the purity of silicon monoxide, and taking a long time to react. Suitable for large-scale industrial production, improving deposition efficiency and production yield, and reducing the effect of gas usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

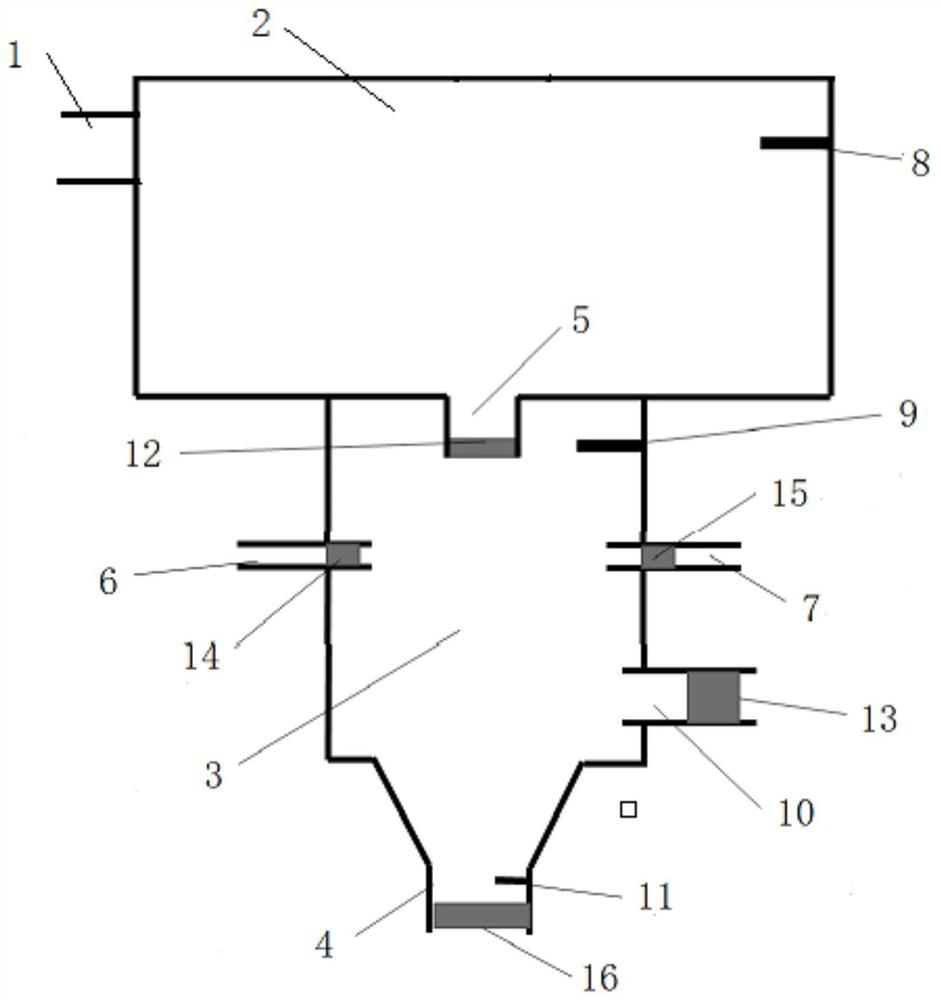

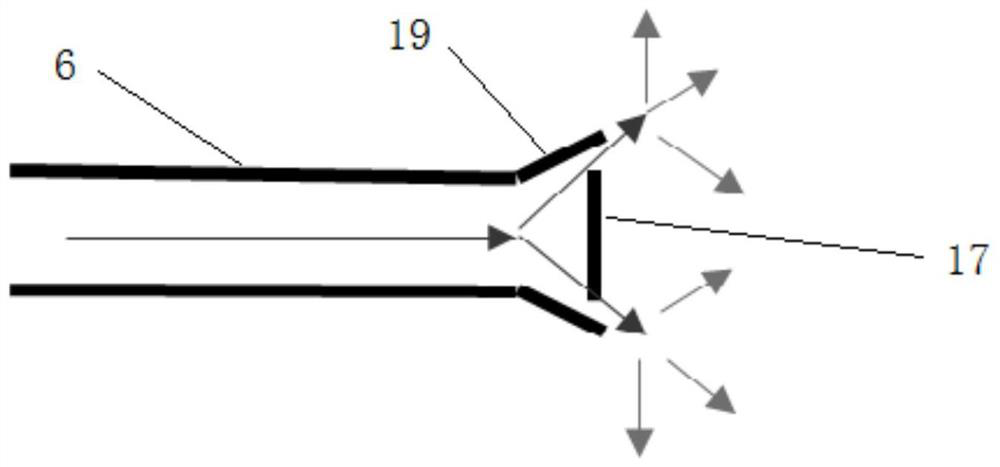

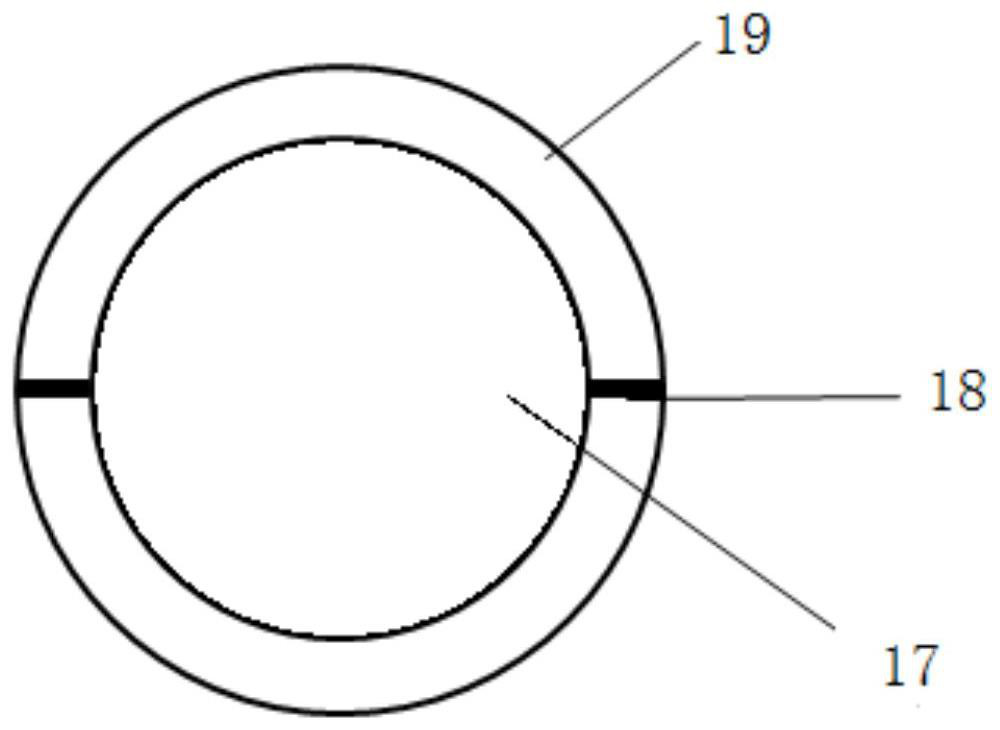

Embodiment 1

[0034] The device for preparing high-purity silicon monoxide in batches according to the present invention, the structural diagram of the device is as follows figure 1 As shown, it includes feed port 1, reaction zone 2, deposition zone 3 and discharge port 4, feed port 1 is connected with reaction zone 2, feed port 4 is connected with deposition zone 3, and reaction zone 2 passes silicon monoxide gas The transfer port 5 communicates with the deposition area 3, and the deposition area 3 is also provided with a cooling device. The cooling device includes a cooling gas inlet pipe 6 and a cooling gas outlet pipe 7. The cooling gas inlet pipe 6 has a horn outlet end, and the horn outlet end is also provided with a cooling gas sprayed into the deposition area 3 in a radial manner along the inner wall of the cooling gas inlet pipe 6. The baffle 17, the cooling gas inlet pipe 6 is arranged on one side of the deposition area 3, and the cooling gas outlet pipe 7 is arranged on the other...

Embodiment 2

[0041] The device for preparing high-purity silicon monoxide in batches according to the present invention, the structural diagram of the device is as follows figure 1 As shown, it includes feed port 1, reaction zone 2, deposition zone 3 and discharge port 4, feed port 1 is connected with reaction zone 2, feed port 4 is connected with deposition zone 3, and reaction zone 2 passes silicon monoxide gas The transfer port 5 communicates with the deposition area 3, and the deposition area 3 is also provided with a cooling device. The cooling device includes a cooling gas inlet pipe 6 and a cooling gas outlet pipe 7. The cooling gas inlet pipe 6 has a horn outlet end, and the horn outlet end is also provided with a cooling gas sprayed into the deposition area 3 in a radial manner along the inner wall of the cooling gas inlet pipe 6. The baffle 17, the cooling gas inlet pipe 6 is arranged on one side of the deposition area 3, and the cooling gas outlet pipe 7 is arranged on the other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com