Radioactive nuclear waste solidified iron phosphate glass with low alloy corrosivity and preparation method of radioactive nuclear waste solidified iron phosphate glass

A phosphate glass and corrosive technology, which is applied in the field of radioactive nuclear waste solidified iron phosphate glass and its preparation, achieves the effects of low corrosiveness, strong practicability and improved photo-alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

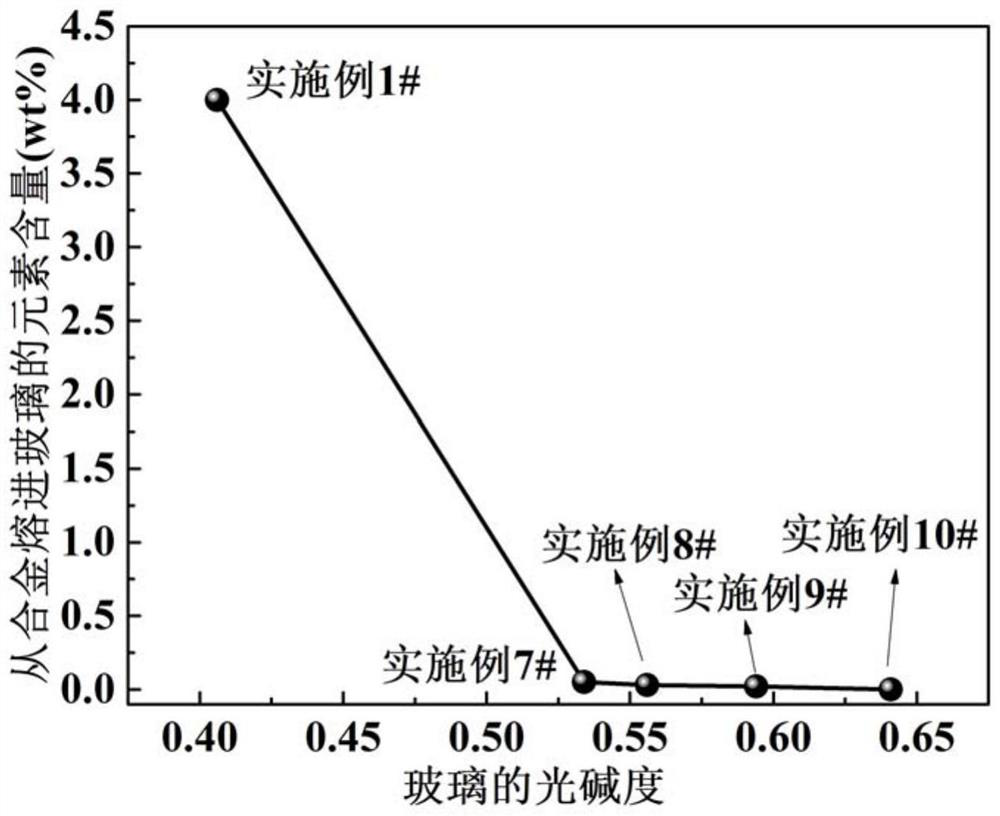

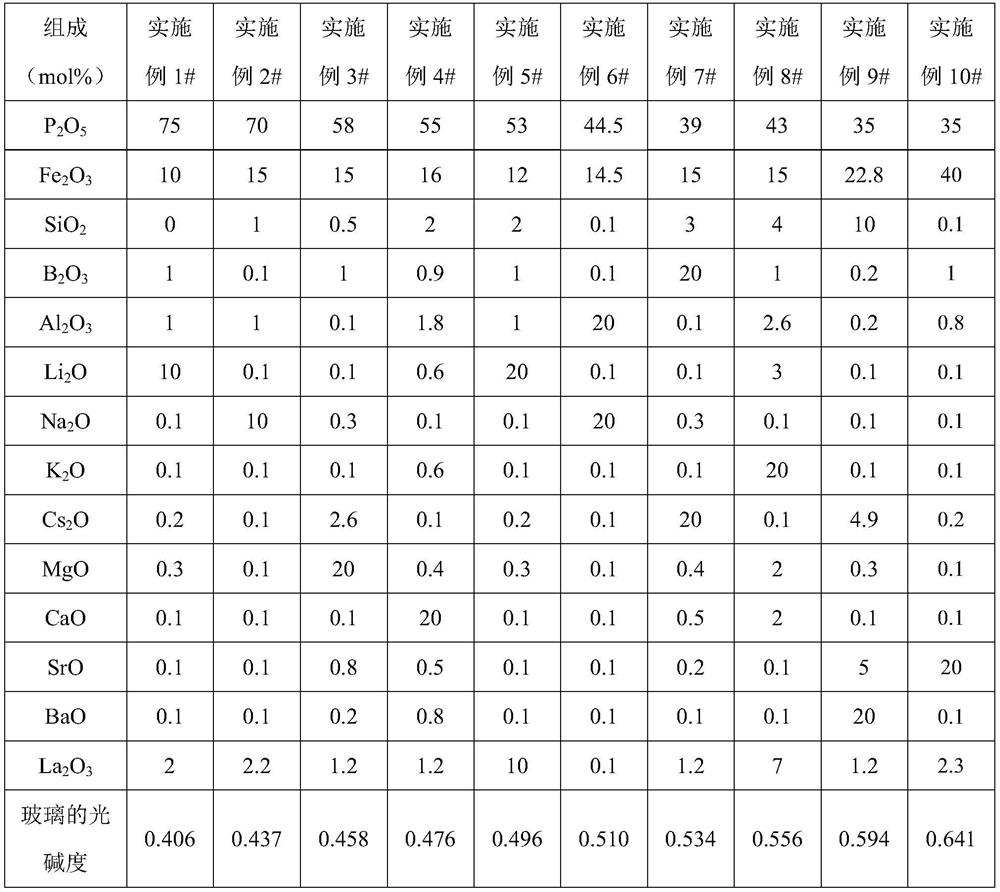

[0028] The raw material composition is shown in Table 1, and the specific preparation process is as follows:

[0029] (1) Ingredients: According to the above glass composition, mainly P 2 o 5 , Fe 2 o 3 , SiO 2、H 3 BO 3 、Al 2 o 3 , Li 2 CO 3 、Na 2 CO 3 、K 2 CO 3 、Cs 2 CO 3 , MgCO 3 , CaCO 3 , SrCO 3 、BaCO 3 as raw material, and according to the quality of 75.94g P 2 o 5 , 11.39g Fe 2 o 3 , 0gSiO 2 , 0.88g H 3 BO 3 , 0.73g Al 2 o 3 , 5.27g Li 2 CO 3 , 0.08g Na 2 CO 3 , 0.10g K 2 CO 3 , 0.46g Cs 2 CO 3 , 0.18g MgCO 3 , 0.07g CaCO 3 , 0.11g SrCO 3 , 0.14g BaCO 3 , 4.65g La 2 o 3 Weigh each raw material;

[0030] (2) Ball milling and mixing: put the above-mentioned raw materials into a drum type ball mill to fully grind and mix evenly;

[0031] (3) Melting and homogenizing: melting the mixed powder at 1000° C. for 2 hours, stirring and homogenizing to obtain homogenized molten glass;

[0032] (4) Molding: pouring the molten glass after m...

Embodiment 2

[0036] The raw material composition is shown in Table 1, and the specific preparation process is as follows:

[0037] (1) Ingredients: According to the glass composition, mainly P 2 o 5 , Fe 2 o 3 , SiO 2 、H 3 BO 3 、Al 2 o 3 , Li 2 CO 3 、Na 2 CO 3 、K 2 CO 3 、Cs 2 CO 3 , MgCO 3 , CaCO 3 , SrCO 3 、BaCO 3 as raw material, and according to the quality of 69.05g P 2 o 5 , 16.65g Fe 2 o 3 , 0.42g SiO 2 , 0.09g H 3 BO 3 , 0.71g Al 2 o 3 , 0.05g Li 2 CO 3 , 7.37g Na 2 CO 3 , 0.10g K 2 CO 3 , 0.23gCs 2 CO 3 , 0.06g MgCO 3 , 0.07g CaCO 3 , 0.10g SrCO 3 , 0.14g BaCO 3 , 4.98g La 2 o 3 Weigh each raw material;

[0038] (2) Ball milling and mixing: put the above-mentioned raw materials into a drum type ball mill to fully grind and mix evenly;

[0039] (3) Melting and homogenizing: melting the mixed powder at a temperature of 1020° C. for 2.2 hours, stirring and homogenizing to obtain a homogenized molten glass;

[0040] (4) Molding: pouring the m...

Embodiment 3

[0044] The raw material composition is shown in Table 1, and the specific preparation process is as follows:

[0045] (1) Ingredients: According to the glass composition, mainly P 2 o 5 , Fe 2 o 3 , SiO 2 、H 3 BO 3 、Al 2 o 3 , Li 2 CO 3 、Na 2 CO 3 、K 2 CO 3 、Cs 2 CO 3 , MgCO 3 , CaCO 3 , SrCO 3 、BaCO 3 as raw material, and according to the quality of 59.07g P 2 o 5 , 17.19g Fe 2 o 3 , 0.22g SiO 2 , 0.89g H 3 BO 3 , 0.07g Al 2 o 3 , 0.05g Li 2 CO 3 , 0.23g Na 2 CO 3 , 0.10g K 2 CO 3 , 6.08gCs 2 CO 3 , 12.10g MgCO 3 , 0.07g CaCO 3 , 0.85g SrCO 3 , 0.28g BaCO 3 , 2.81g La 2 o 3 Weigh each raw material;

[0046] (2) Ball milling and mixing: put the above-mentioned raw materials into a drum type ball mill to fully grind and mix evenly;

[0047] (3) Melting and homogenizing: melting the mixed powder at 1050° C. for 2.5 hours, stirring and homogenizing to obtain homogenized molten glass;

[0048] (4) Molding: pouring the molten glass after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com