Regenerated environment-friendly water purification brick and preparation method thereof

A water purification and environmental protection technology, applied in the field of recycled environmental protection water purification bricks and its preparation, to achieve the effect of reducing shrinkage cracking, reducing density and improving water purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

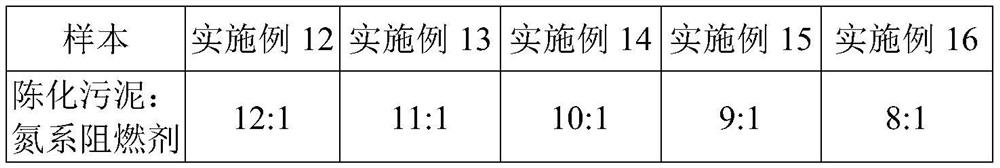

Examples

Embodiment 1~5

[0047] Embodiment 1 is taken as an example below for description.

Embodiment 1

[0049] In Example 1, the recycled environmental protection water purification brick is prepared according to the following steps:

[0050] (1) This step is divided into an aging stage and a calcination stage, and immediately enters the calcination stage after the aging stage ends, and the steps of the aging stage and the calcination stage are as follows:

[0051] Aging stage: Mix 60kg deionized water and 6kg sodium lauryl sulfate evenly to obtain an aging liquid, mix the sludge with a moisture content of 5% and the aging liquid according to a weight ratio of 10:1, and then statically Placed for 30h to obtain aged sludge;

[0052] Calcination stage: put the aged sludge in the closed heating equipment, fill the heating chamber with nitrogen until the nitrogen exhausts the air in the heating chamber, then heat the aged sludge to 360°C, After holding at 360°C for 40 minutes, carbonized sludge was obtained;

[0053] (2) 30kg of carbonized sludge, 16kg of regenerated aggregate, 12...

Embodiment 6

[0061] The difference between this example and Example 3 is that the recycled environmental protection water purification brick is prepared according to the following steps:

[0062] (1) This step is divided into an aging stage and a calcination stage, and immediately enters the calcination stage after the aging stage ends, and the steps of the aging stage and the calcination stage are as follows:

[0063] Aging stage:

[0064] ① Seal the sludge with a moisture content of 63% at room temperature for 8 days to obtain fermented sludge;

[0065] ②Spray the sodium carbonate solution into the fermented sludge according to the consumption of 40g of sodium carbonate per kg of fermented sludge, and then perform 7 freeze-thaw cycles on the fermented sludge in the temperature range of -25°C to 15°C, freeze-thaw The highest temperature of the cycle is 15°C, the lowest temperature is -25°C, and the heating rate and cooling rate are both 5°C / h. After the freeze-thaw cycle is over, the fer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com