Phosphogypsum curb and preparation method thereof

A technology of phosphogypsum and dentures, which is applied in the field of phosphogypsum dentures and its preparation, can solve the problems of large amount of gel material used, long production cycle of dentures, and low compressive strength, so as to speed up hardening and reduce production Good effect of cost and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

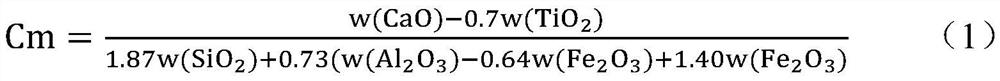

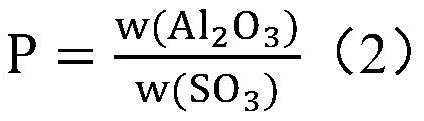

Method used

Image

Examples

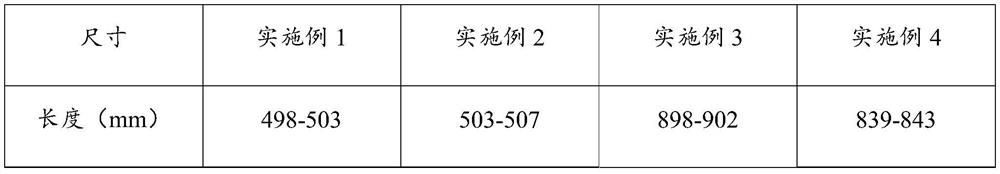

Embodiment 1

[0050] A phosphogypsum denture, comprising the following components in parts by weight:

[0051] 450 parts of modified phosphogypsum, 200 parts of stone, 300 parts of aggregate, 31 parts of ash, 5 parts of polyvinyl alcohol, 1 part of calcium formate, 2 parts of hydroxypropyl methylcellulose, and 11 parts of accelerator.

[0052] The preparation method comprises the following steps:

[0053] 1) Raw material preparation: The modified phosphogypsum, stones, aggregates, ash, polyvinyl alcohol, calcium formate, hydroxypropyl methylcellulose and accelerator are weighed by computer automation and added to the closed Mixer is stirred to obtain dry mixture;

[0054] 2) According to step 1), add 0.09 parts of water and stir to obtain a uniform semi-dry material;

[0055] 3) Stamping forming: according to step 2) the semi-dry material obtained is filled into the curb mould, the height of the filler does not exceed the height of the mold, the mold filled with the semi-dry material is v...

Embodiment 2

[0065] A phosphogypsum denture, comprising the following components in parts by weight:

[0066] 350 parts of modified phosphogypsum, 156 parts of stone, 233 parts of aggregate, 24 parts of ash, 4 parts of polyvinyl alcohol, 0.8 part of calcium formate, 1.6 parts of hydroxypropyl methylcellulose, and 8.6 parts of accelerator.

[0067] The preparation method comprises the following steps:

[0068] 1) Raw material preparation: The modified phosphogypsum, stones, aggregates, ash, polyvinyl alcohol, calcium formate, hydroxypropyl methylcellulose and accelerator are weighed by computer automation and added to the closed Mixer is stirred to obtain dry mixture;

[0069] 2) According to step 1), add 0.08 parts of water and stir to obtain a uniform semi-dry material;

[0070] 3) Stamping forming: according to step 2) the semi-dry material obtained is filled into the curb mould, the height of the filler does not exceed the height of the mold, the mold filled with the semi-dry material...

Embodiment 3

[0080] A phosphogypsum denture, comprising the following components in parts by weight:

[0081] 550 parts of modified phosphogypsum, 244 parts of stone, 367 parts of aggregate, 38 parts of ash, 6 parts of polyvinyl alcohol, 1.2 parts of calcium formate, 2.4 parts of hydroxypropyl methylcellulose, and 13.5 parts of accelerator.

[0082] The preparation method comprises the following steps:

[0083]1) Raw material preparation: The modified phosphogypsum, stones, aggregates, ash, polyvinyl alcohol, calcium formate, hydroxypropyl methylcellulose and accelerator are weighed by computer automation and added to the closed Mixer is stirred to obtain dry mixture;

[0084] 2) According to step 1), add 0.1 part of water and stir to obtain a uniform semi-dry material;

[0085] 3) Stamping forming: according to step 2) the semi-dry material obtained is filled into the curb mould, the height of the filler does not exceed the height of the mold, the mold filled with the semi-dry material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com