Eugenol-based polyol and preparation method thereof

A eugenol-based, polyol technology, applied in the preparation of thioethers, organic chemistry, etc., can solve the problems of high energy consumption, single rigid segment or flexible segment, and complicated preparation methods, and achieves easy products and efficient and rapid reactions. , Solve the effect of the cumbersome preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

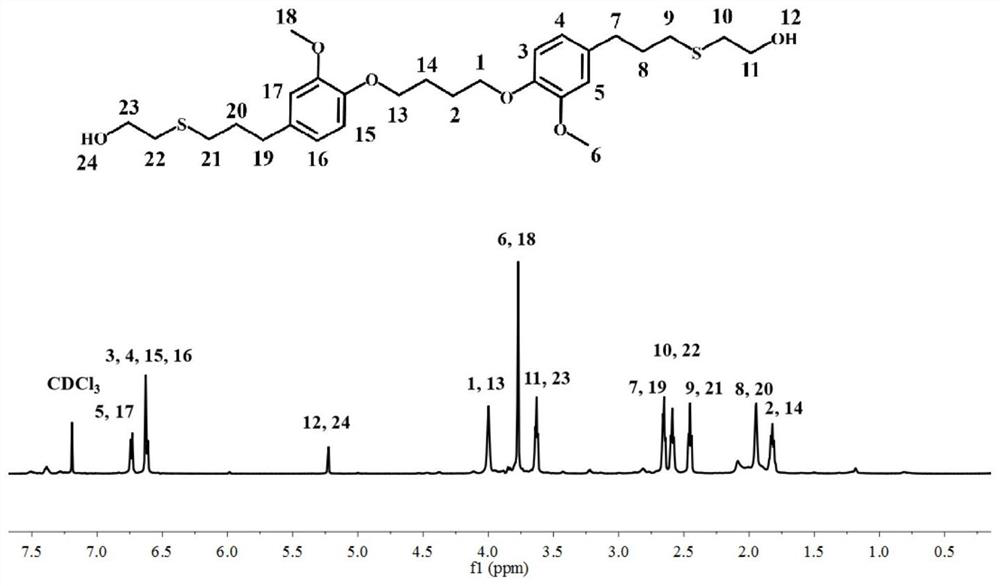

Examples

preparation example Construction

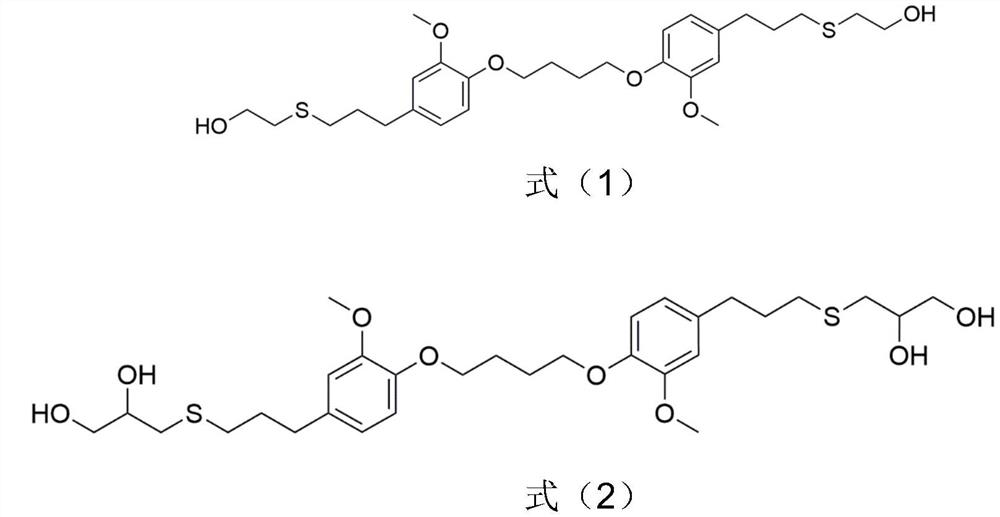

[0026] The preparation method of eugenol-based polyol of the present invention comprises the steps:

[0027] Step 1: According to the amount of substances, 100 parts of eugenol, 1300-1600 parts of ethanol, 60-90 parts of potassium carbonate, and 3-5 parts of potassium iodide are mixed by a magnetic stirrer at a temperature of 25°C. When the color of the solution turns dark green, dissolve 50-70 parts of 1,4-dibromobutane in 10 parts of ethanol, and slowly drop it into the reaction system through a constant pressure funnel. Then, raise the temperature to 70-80°C and heat to reflux for 8-12h; after the reaction, cool to room temperature, and keep the crude product for 16 hours to fully crystallize, filter the mixture, wash the obtained solid with hot water, and re- Crystallize and then dry in a vacuum oven at 60°C, and the resulting white powder is 1,4-bis(4-allyl-2-methoxyphenoxy)butane.

[0028] Step 2: According to the amount of substance, 20 parts of intermediate product 1,...

Embodiment 1

[0037] 1. Preparation of Eugenol-based Polyols

[0038]Step 1: According to the amount of substances, 100 parts of eugenol, 1300 parts of ethanol, 60 parts of potassium carbonate, and 3 parts of potassium iodide were mixed by a magnetic stirrer at a temperature of 25°C. When the color of the solution turned dark green, 50 parts of 1,4-dibromobutane was dissolved in 10 parts of ethanol, and slowly added dropwise into the reaction system through a constant pressure funnel. Then, the temperature was raised to 70°C and heated to reflux for 8h; after the reaction, cooled to room temperature, and the crude product was kept for 16 hours to fully crystallize, the mixture was filtered, the obtained solid was washed with hot water, and recrystallized, and then in After drying in a vacuum oven at 60°C, the resulting white powder is 1,4-bis(4-allyl-2-methoxyphenoxy)butane.

[0039] Step 2. According to the amount of substance, 20 parts of intermediate product 1,4-bis(4-allyl-2-methoxyphe...

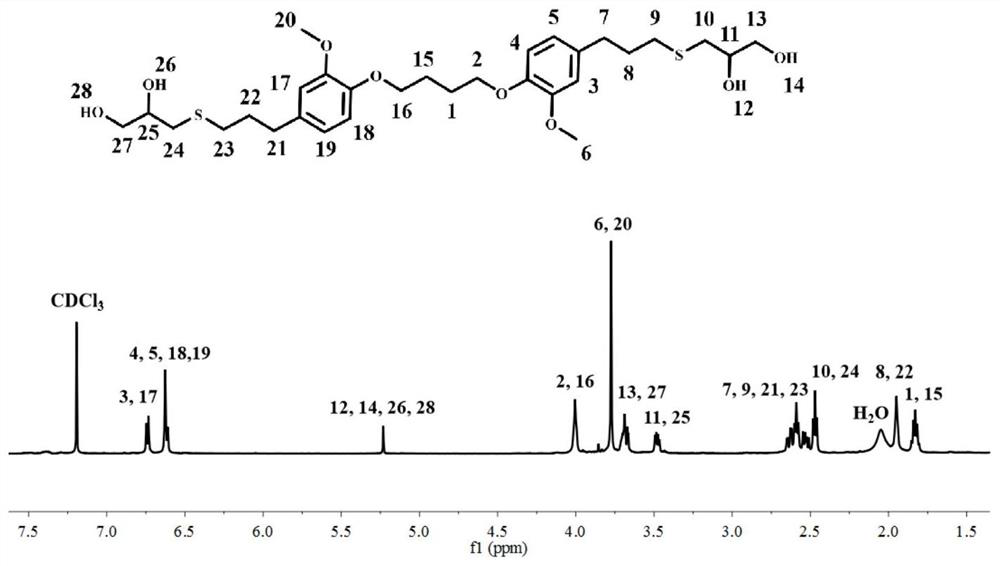

Embodiment 2

[0043] 1. Preparation of Eugenol-based Polyols

[0044] Step 1: According to the amount of substances, 100 parts of eugenol, 1450 parts of ethanol, 75 parts of potassium carbonate and 4 parts of potassium iodide were mixed by a magnetic stirrer at a temperature of 25°C. When the color of the solution turned dark green, 60 parts of 1,4-dibromobutane was dissolved in 10 parts of ethanol, and slowly added dropwise into the reaction system through a constant pressure funnel. Then, the temperature was raised to 75° C. and heated to reflux for 10 h; after the reaction was completed, it was cooled to room temperature, and the crude product was kept for 16 hours to fully crystallize, the mixture was filtered, and the obtained solid was washed with hot water and recrystallized, and then in After drying in a vacuum oven at 60°C, the resulting white powder is 1,4-bis(4-allyl-2-methoxyphenoxy)butane.

[0045] Step 2. According to the amount of substance, 20 parts of intermediate product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com