UV photocuring composition with low moisture transmittance and preparation method thereof

A technology of moisture vapor transmission rate and light curing, which is applied in the field of sealing rings, can solve the problems of low strength and high moisture vapor transmission rate, and achieve the effect of good interaction and low moisture vapor transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

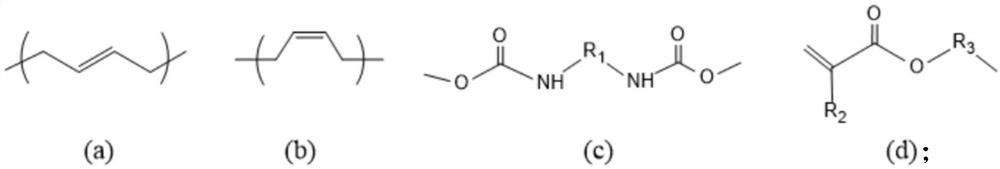

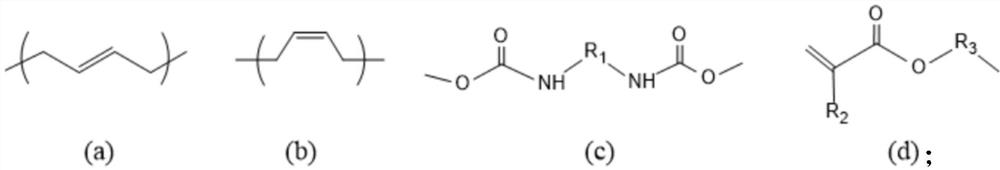

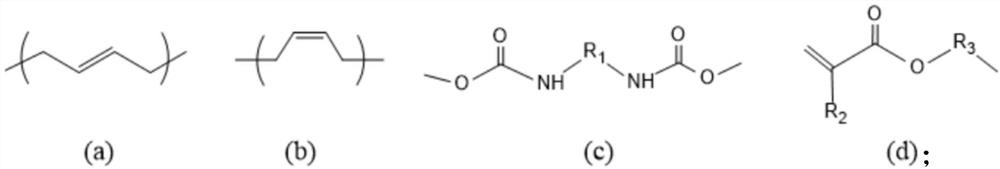

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a method for preparing the UV photocurable composition with low moisture vapor transmission rate described in the above technical solution, comprising the following steps:

[0060] a) mixing acrylate monomers, polybutadiene-modified urethane acrylate oligomers, photoinitiators and chain transfer agents for the first time to obtain a mixture;

[0061] b) adding hydrophobic fumed silica to the mixture obtained in step a), performing second mixing, and obtaining a UV photocurable composition with low moisture vapor transmission rate after defoaming.

[0062] In the invention, the acrylate monomer, polybutadiene-modified urethane acrylate oligomer, photoinitiator and chain transfer agent are mixed for the first time to obtain the mixture. In the present invention, the acrylate monomer, polybutadiene-modified urethane acrylate oligomer, photoinitiator and chain transfer agent are the same as those in the above technical solution, and will ...

Embodiment 1~6 and comparative example 1~4

[0089] Referring to Tables 1-2, Table 1 is the raw material composition table of Examples 1-6, and Table 2 is the raw material composition table of Comparative Examples 1-4.

[0090] The raw material composition table of table 1 embodiment 1~6

[0091]

[0092]

[0093] The raw material composition table of table 2 comparative examples 1~4

[0094] a h i b c d e f g Comparative example 1 - 56 - 14 30 3 3 5 5 Comparative example 2 - - 56 14 30 3 3 5 5 Comparative example 3 - 28 28 14 30 3 3 5 5 Comparative example 4 70 - - - 30 3 3 5 5

[0095] The specific preparation method is as follows:

[0096] Referring to Table 1-2 raw material composition table, first dissolve all photoinitiator e and part of acrylate monomer c into acrylate monomer c at a mass ratio of 1:2, and then add oligomer 1 into the reactor , oligomer 2, chain transfer agent d, remaining acrylate monomer c, disperse at 20rpm fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com