Intelligent lighting system of floating production oil loading and unloading device

A technology of intelligent lighting and floating production, which is applied in energy-saving control technology, fire alarms, instruments, etc., to achieve the effects of prolonging life, providing work convenience, and realizing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

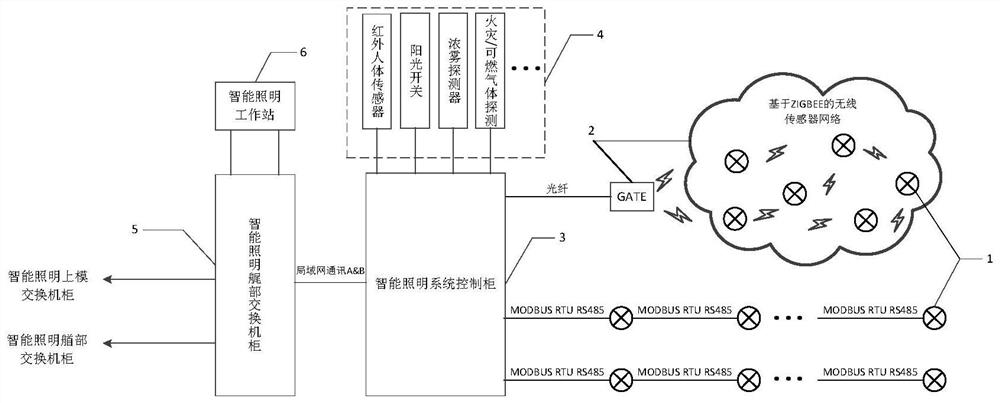

[0029] This embodiment provides an intelligent lighting system for FPSO, including an intelligent lighting fixture 1, an intelligent lighting gateway 2, an intelligent lighting system control cabinet 3, a data acquisition module 4, an intelligent lighting switching cabinet 5, and an intelligent lighting workstation 6; the system framework Figure such as figure 1As shown, the intelligent lighting system control cabinet 3 collects status information such as voltage, current, and fault of the intelligent lighting fixture 1 transmitted by the wired sensor network and the wireless sensor network, and the environmental data collected by the data acquisition module 4 is also connected to the intelligent lighting system. The control cabinet 3 transmits the signal to the intelligent lighting workstation 6 through the intelligent lighting switch cabinet 5 . Then, the intelligent lighting workstation 6 issues a command to control the intelligent lighting fixture 1 according to the intell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com