BiCuSnNiP series high-temperature lead-free solder and preparation method thereof

A lead-free solder, high temperature technology, used in welding equipment, welding/cutting media/materials, welding media, etc., can solve the problems of high brittleness and low wettability, and achieve high welding bonding force, fine grain size, and reduced The effect of solder cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

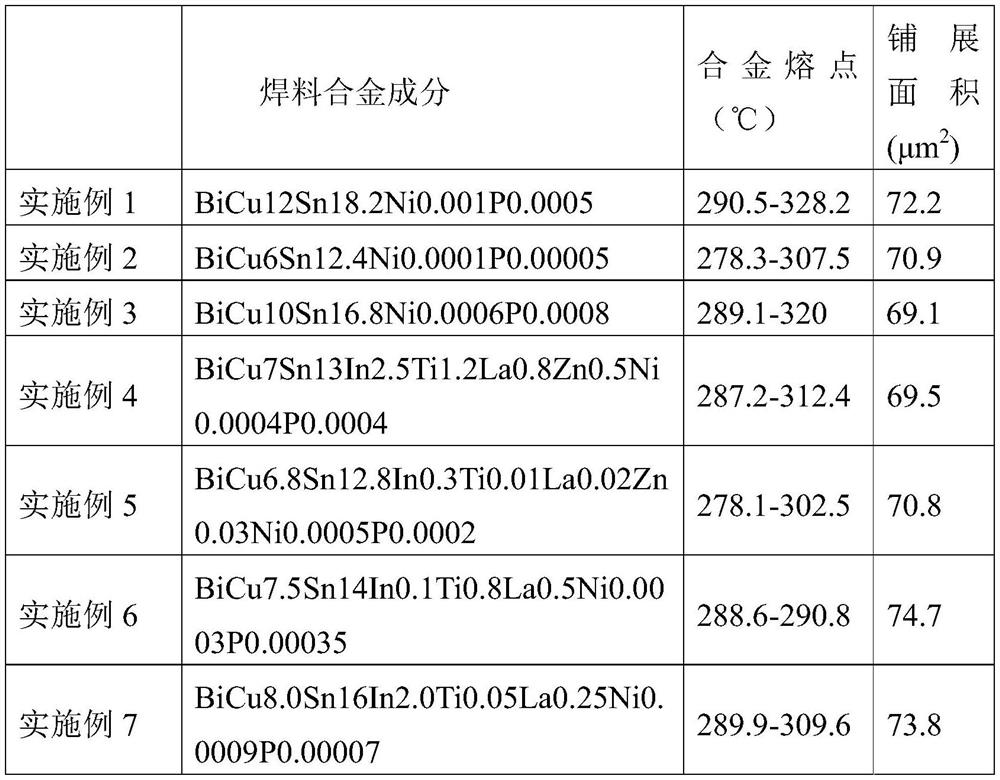

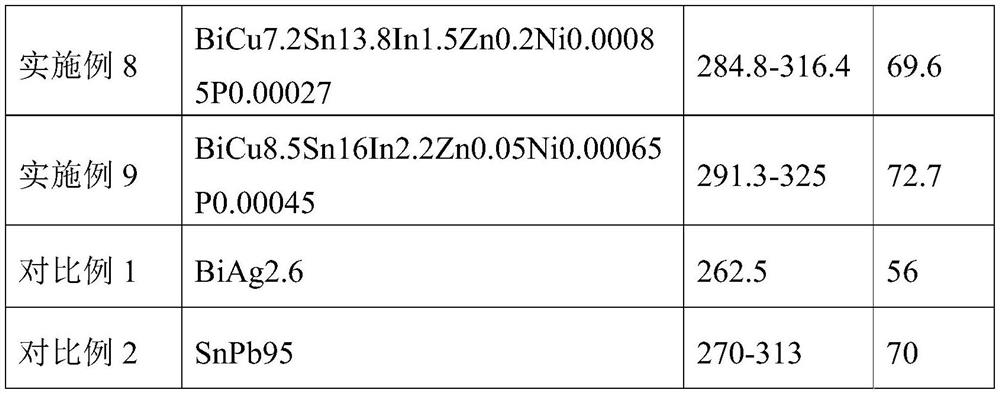

Embodiment 1

[0049] A BiCuSnNiP high-temperature lead-free solder alloy used in the field of high-temperature soldering, the lead-free solder alloy contains: Cu 12%, Sn 18.2%, Ni: 1000ppm, P: 500ppm, and the rest are Bi and unavoidable impurities, the lead-free solder alloy has a melting point of 290.5-328.2°C. The method for preparing the lead-free solder alloy comprises the following steps:

[0050] 1) Metals Bi and Cu, Bi and Ni, Bi and P with a purity of 99.99wt.% were added to the vacuum melting furnace according to the weight ratio, and the vacuum treatment was carried out to 1×10 -1 Pa, after filling with nitrogen; heating to 650-700°C for melting, while adding electromagnetic stirring to make the alloy composition uniform, and then vacuum casting to prepare Bi-Cu10, Bi-Ni5, Bi-P2 master alloys;

[0051] 2) Add the prepared Bi-Cu, Bi-Ni and Bi-P master alloys and metal Sn into the melting furnace according to the alloy ratio. Cover the surface of the alloy with an anti-oxidation s...

Embodiment 2

[0053] A BiCuSnNiP high-temperature lead-free solder alloy used in the field of high-temperature soldering, the lead-free solder alloy contains: Cu 6%, Sn 12.4%, Ni: 100ppm, P: 50ppm, and the rest are Bi and unavoidable impurities, the melting point of the lead-free solder alloy is 288.3-307.5°C. The method for preparing the lead-free solder alloy is the same as that in Example 1 except that the alloy ratio is different.

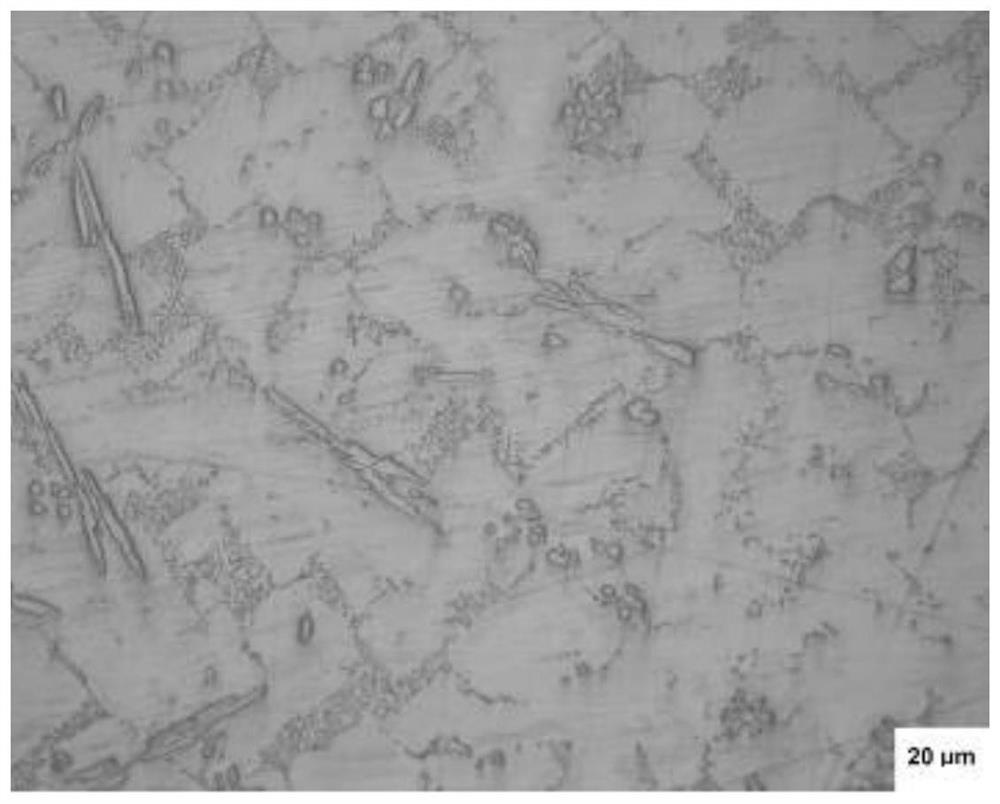

[0054] The photo of the metallographic structure of the solder alloy prepared in this embodiment is as follows figure 1 As shown, the microstructure distribution of the alloy can be seen from the figure.

Embodiment 3

[0056] A BiCuSnNiP high-temperature lead-free solder alloy used in the field of high-temperature soldering, the lead-free solder alloy contains: Cu 10%, Sn 16.8%, Ni: 600ppm, P: 800ppm, and the rest are Bi and unavoidable impurities, the melting point of the lead-free solder alloy is 289.1-320°C. The method for preparing the lead-free solder alloy is the same as that in Example 1 except that the alloy ratio is different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com