Floating-fiber-free glass fiber reinforced nylon composite material and preparation method thereof

A technology of nylon composite material and non-floating fiber, which is applied in the field of non-floating fiber glass fiber reinforced nylon composite material and its preparation, to achieve the effect of wide source, complete dimensional stability and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

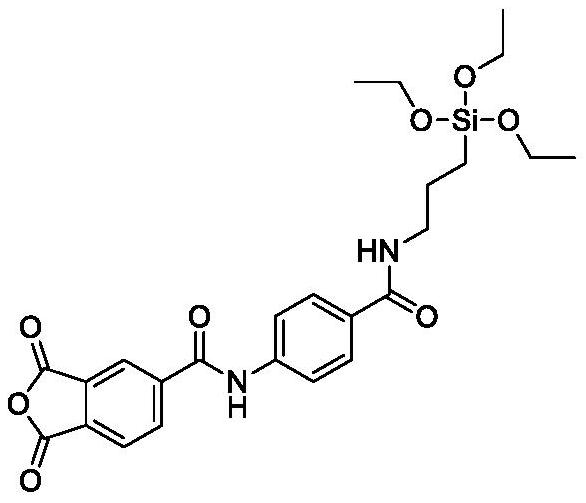

[0033] This embodiment provides a modified glass fiber, which is made by the following steps:

[0034] Step A1. Mix 0.1mol of p-aminobenzoic acid, 0.3mol of thionyl chloride and 130mL of ethyl acetate, heat up to 58°C under stirring, and keep the temperature for 2 hours. After the reaction, remove the ethyl acetate by distillation under reduced pressure to obtain an intermediate product 1;

[0035] Step A2, mix 0.1mol KH-550 and 50mL chloroform, cool down to 0°C in an ice-water bath, add dropwise 100mL chloroform solution of intermediate product 1, keep the temperature at 0°C throughout the dropping process, finish the dropping within 1 hour, and raise the temperature to 19 ℃, stirring and reacting for 2 hours, after the reaction, chloroform was distilled off under reduced pressure to obtain intermediate product 2, and the chloroform solution of intermediate product 1 was prepared by mixing intermediate product 1 and chloroform according to 0.1mol:100mL;

[0036] Step A3. Mix...

Embodiment 2

[0039] This embodiment provides a modified glass fiber, which is made by the following steps:

[0040] Step A1. Mix 0.1mol of p-aminobenzoic acid, 0.3mol of thionyl chloride and 140mL of ethyl acetate, heat up to 60°C under stirring, and keep the temperature for 2.5h. After the reaction, remove the ethyl acetate by distillation under reduced pressure to obtain intermediate Product 1;

[0041] Step A2, mix 0.1mol KH-550 and 60mL chloroform, cool down to 2°C in an ice-water bath, add dropwise 100mL chloroform solution of intermediate product 1, keep the temperature at 2°C throughout the dropping process, finish the dropwise addition within 1 hour, and raise the temperature to 20°C ℃, stirring and reacting for 2 hours, after the reaction, chloroform was distilled off under reduced pressure to obtain intermediate product 2, and the chloroform solution of intermediate product 1 was prepared by mixing intermediate product 1 and chloroform according to 0.1mol:100mL;

[0042] Step A3...

Embodiment 3

[0045] This embodiment provides a modified glass fiber, which is made by the following steps:

[0046] Step A1. Mix 0.1mol of p-aminobenzoic acid, 0.3mol of thionyl chloride and 150mL of ethyl acetate, heat up to 62°C under stirring, and keep the temperature for 3 hours. After the reaction, remove the ethyl acetate by distillation under reduced pressure to obtain an intermediate product 1;

[0047] Step A2, mix 0.1mol KH-550 and 70mL chloroform, cool down to 5°C in an ice-water bath, add dropwise 100mL chloroform solution of intermediate product 1, keep the temperature at 5°C throughout the dropping process, finish the dropwise addition within 1 hour, and raise the temperature to 21 ℃, stirring and reacting for 2 hours, after the reaction, chloroform was distilled off under reduced pressure to obtain intermediate product 2, and the chloroform solution of intermediate product 1 was prepared by mixing intermediate product 1 and chloroform according to 0.1mol:100mL;

[0048] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com