A kind of die-casting aluminum alloy applied to motor casing and preparation method thereof

A technology for casting aluminum alloy and motor housing, applied in the field of aluminum alloy, can solve the problems of increasing the cost of aluminum alloy, restricting the use of aluminum alloy, expensive rare earth modifier, etc., and achieves low cost, excellent corrosion resistance and wear resistance. Performance, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

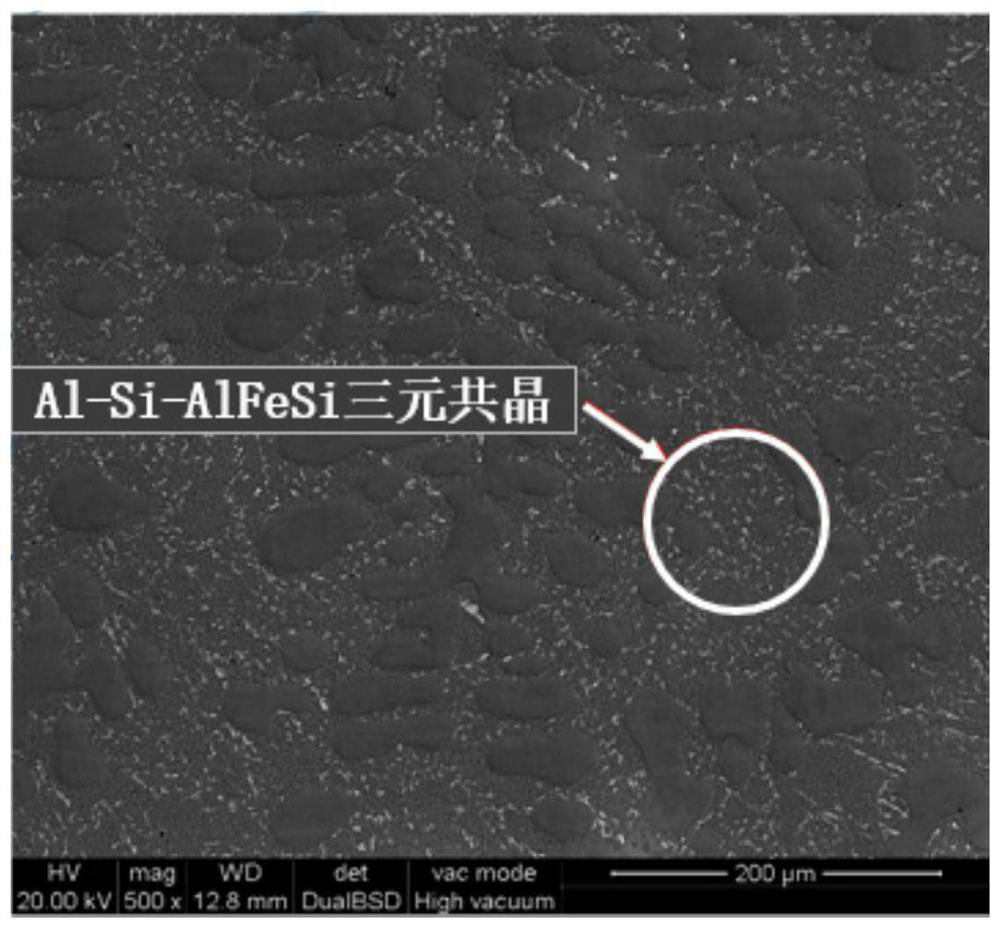

Image

Examples

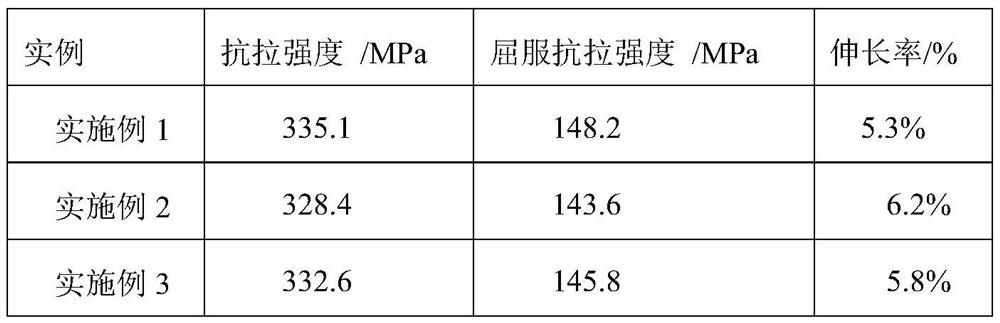

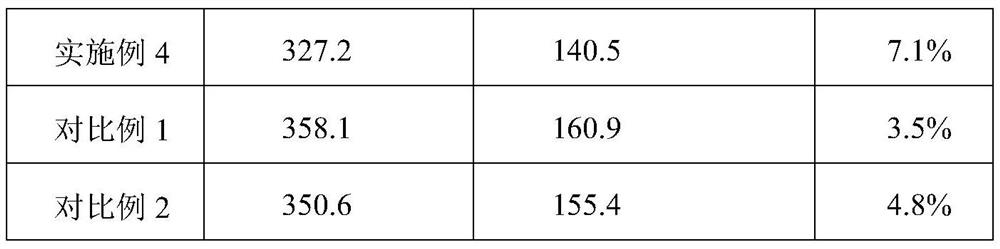

Embodiment 1

[0038] Embodiment 1 A kind of die-casting aluminum alloy applied to motor housing

[0039] The chemical composition of the 0.5 ton alloy prepared by mass percentage includes: the content of Si is 10.62%, the content of Cu is 0.06%, the content of Fe is 0.72%, the content of Mn is 0.31%, the content of Ti is 0.12%, and the content of Mg is 0.12%. 0.2%, Pb content is 0.09%, Sn content is 0.05% and the rest is Al.

[0040] The preparation method is:

[0041] (1) proportion according to the formula, add the aluminum ingot whose mass fraction is 70% into the smelting furnace, then put the prepared Fe, Mn, Cu, Ti, Pb materials into the smelting furnace, heat up and dissolve, and obtain mixture A;

[0042] (2) after the mixture A is completely melted in the furnace, first add the aluminum ingot of the remaining mass, then add silicon metal, and stir the melt, and heat up simultaneously to obtain the melt B;

[0043] (3) Add the remaining Mg and Sn raw materials to the solution B, a...

Embodiment 2

[0046] Embodiment 2 A kind of die-casting aluminum alloy applied to motor housing

[0047] The chemical composition of the 0.5 ton alloy prepared by mass percentage includes: the content of Si is 10.98%, the content of Cu is 0.07%, the content of Fe is 0.61%, the content of Mn is 0.40%, the content of Ti is 0.10%, and the content of Mg is 0.10%. 0.3%, Pb content is 0.09%, Sn content is 0.05% and the rest is Al.

[0048] The preparation method is:

[0049] (1) proportion according to the formula, add the aluminum ingot whose mass fraction is 90% into the smelting furnace, then put the prepared Fe, Mn, Cu, Ti, Pb materials into the smelting furnace, heat up and dissolve, and obtain mixture A;

[0050] (2) after the mixture A is completely melted in the furnace, first add the aluminum ingot of the remaining mass, then add silicon metal, and stir the melt, and heat up simultaneously to obtain the melt B;

[0051] (3) Add the remaining Mg and Sn raw materials to the solution B, a...

Embodiment 3

[0053] Embodiment 3 A kind of die-casting aluminum alloy applied to the motor casing

[0054] The chemical composition of the 0.5 ton alloy prepared by mass percentage includes: the content of Si is 10.82%, the content of Cu is 0.08%, the content of Fe is 0.82%, the content of Mn is 0.51%, the content of Ti is 0.08%, and the content of Mg is 0.08%. 0.4%, Pb content is 0.08%, Sn content is 0.05%, and the rest is Al.

[0055] The preparation method is:

[0056] (1) proportion according to the formula, add the aluminum ingot whose mass fraction is 75% into the smelting furnace, then put the prepared Fe, Mn, Cu, Ti, Pb materials into the smelting furnace, heat up and dissolve, and obtain mixture A;

[0057] (2) after the mixture A is completely melted in the furnace, first add the aluminum ingot of the remaining mass, then add silicon metal, and stir the melt, and heat up simultaneously to obtain the melt B;

[0058] (3) Add the remaining Mg and Sn raw materials to the solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com