Rare earth antibacterial and antiviral melt-blown cloth and preparation method thereof

An anti-virus, melt-blown cloth technology, applied in the direction of melt spinning, non-woven fabric, rayon manufacturing, etc., can solve the problems of unsustainable anti-bacterial ability and poor anti-virus protection ability of melt-blown cloth, and achieve high-efficiency anti-bacterial and anti-virus protection. Antiviral efficacy, quality assurance, strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

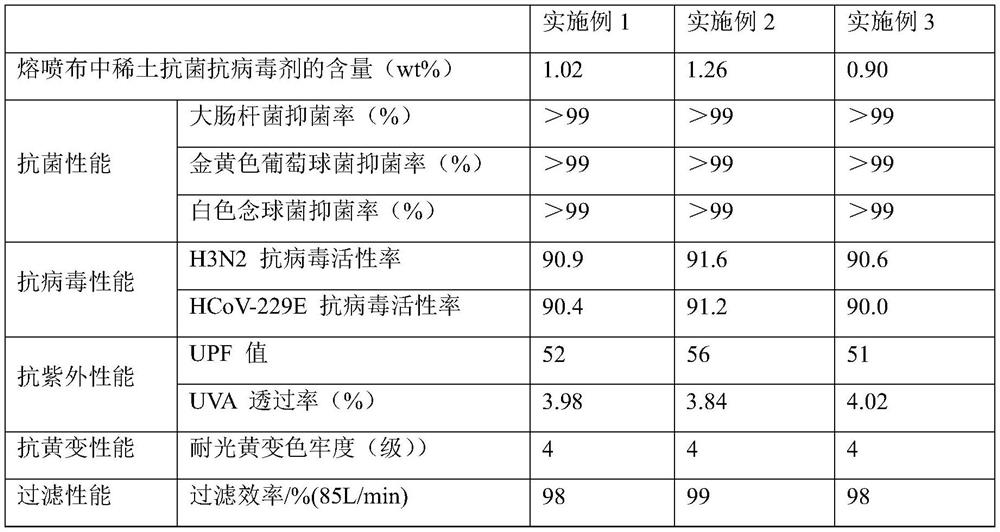

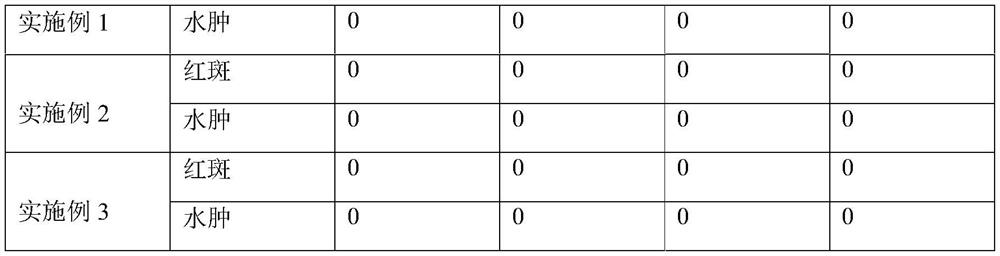

Embodiment 1

[0037] Embodiment 1 A kind of preparation method of rare earth antibacterial and antiviral melt-blown cloth

[0038] Including the following steps:

[0039] 1) Weigh the rare earth antibacterial and antiviral agent, coating agent, and polypropylene base material according to the proportion by mass of 17 parts of antibacterial agent, 2 parts of coating agent, and 81 parts of polypropylene base material, and put them into a high-mixer for blending;

[0040] 2) Put the mixed materials into a twin-screw extruder for melting and blending, the melting temperature is controlled at 220°C, the screw speed is 180 rpm, and the twin-screw extruder is sheared and mixed for 8 minutes; then extruded After cooling, pelletizing and drying, the rare earth antibacterial and antiviral polypropylene masterbatch can be obtained;

[0041] 3) Add 6 parts of rare earth antibacterial and antiviral polypropylene masterbatch and 94 parts of polypropylene base material slices into the screw extruder for ...

Embodiment 2

[0045] Embodiment 2 A kind of preparation method of rare earth antibacterial and antiviral melt-blown cloth

[0046] Including the following steps:

[0047] Including the following steps:

[0048] 1) Weigh the rare earth antibacterial and antiviral agent, coating agent, and polypropylene base material according to the ratio by mass of 18 parts of antibacterial agent, 2.5 parts of coating agent, and 79.5 parts of polypropylene base material, and put them into a high mixing machine for blending;

[0049] 2) Add the mixed materials into a twin-screw extruder for melt blending, the melting temperature is controlled at 230°C, the screw speed is 200 rpm, and the twin-screw extruder is sheared and mixed for 9 minutes; then extruded After cooling, pelletizing and drying, the rare earth antibacterial and antiviral polypropylene masterbatch can be obtained;

[0050] 3) Add 7 parts of rare earth antibacterial and antiviral polypropylene masterbatches and 93 parts of polypropylene substra...

Embodiment 3

[0054] Embodiment 3 A kind of preparation method of rare earth antibacterial and antiviral melt-blown cloth

[0055] Including the following steps:

[0056] 1) Weigh 15 parts of antibacterial agent, 1.5 parts of coating agent, and 83.5 parts of polypropylene substrate according to the ratio by mass of rare earth antibacterial and antiviral agent, coating agent, and polypropylene substrate, and put them into a high-mixing machine for blending;

[0057] 2) Add the mixed materials into a twin-screw extruder for melt blending, the melting temperature is controlled at 235°C, the screw speed is 200 rpm, and the twin-screw extruder is sheared and mixed for 8 minutes; then extruded After cooling, pelletizing and drying, the rare earth antibacterial and antiviral polypropylene masterbatch can be obtained;

[0058] 3) Add 6 parts of rare earth antibacterial and antiviral polypropylene masterbatch and 94 parts of polypropylene base material slices into the screw extruder for melting tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com