Graphite purification process and graphite

A graphite purification and process technology, applied in the graphite purification process and the graphite field, can solve the problems of difficult wastewater treatment, high purification cost, high equipment requirements, etc., and achieve the effect of less waste alkali, low energy consumption, and fewer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

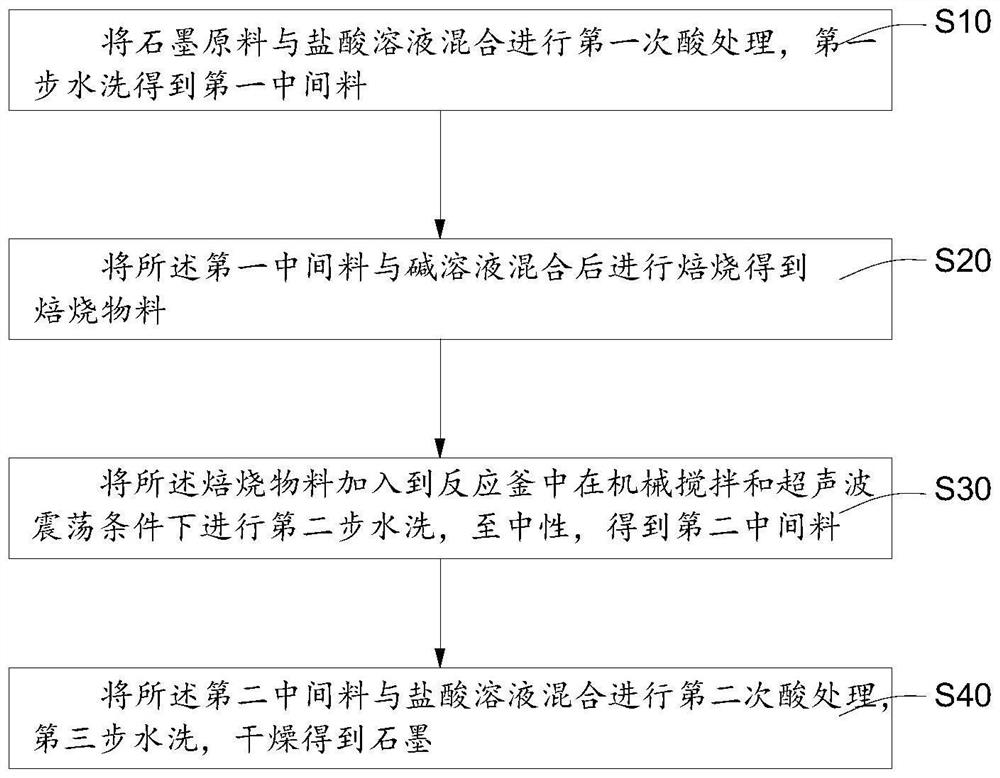

Method used

Image

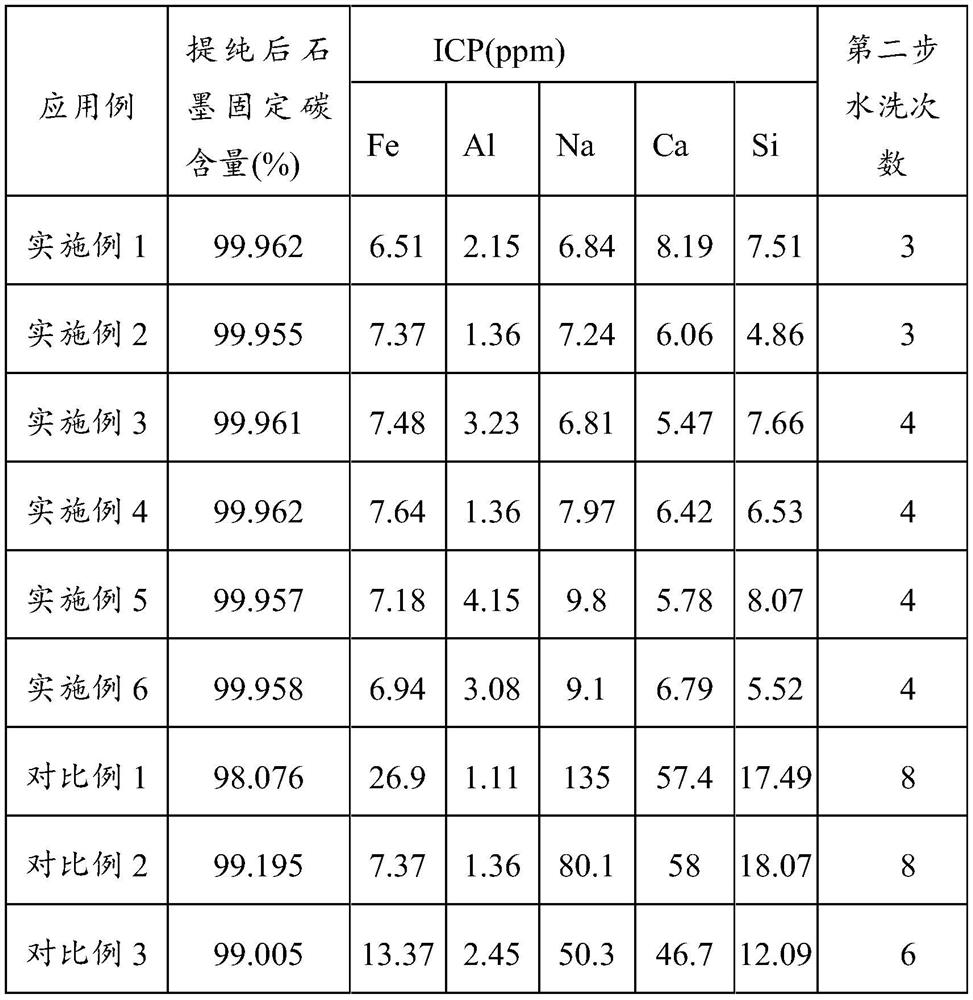

Examples

Embodiment 1

[0086] A graphite purification process, comprising the steps of:

[0087] A natural graphite raw material with a carbon content of 90%-96% is selected, and the graphite raw material is stirred and mixed with 10% hydrochloric acid solution at a temperature of 60° C. for 2 hours. The first mixed material is obtained; the first mixed material is washed to neutrality in the first step to obtain the first intermediate material.

[0088] The obtained first intermediate material and the sodium hydroxide solution with a mass fraction of 40% were mixed and stirred at a ratio of 1:0.8 to obtain a second mixture; the obtained second mixture was calcined at a temperature of 400° C. for 4 hours at a low temperature.

[0089] Wash the roasted material in the second step, first dissolve the roasted material with water (the mass ratio of material to water is 1:2), and then put it into the reaction kettle with stirring and ultrasonic functions under the conditions of mechanical stirring and ul...

Embodiment 2

[0092] A graphite purification process, comprising the steps of:

[0093] A natural graphite raw material with a carbon content of 90%-96% is selected, and the graphite raw material is stirred and mixed with 10% hydrochloric acid solution at a temperature of 80° C. for 4 hours. The first mixed material is obtained; the first mixed material is washed to neutrality in the first step to obtain the first intermediate material. Wherein, the number of times of washing in the first step is the same as in Example 1.

[0094] The obtained first intermediate material and the sodium hydroxide solution with a mass fraction of 60% were mixed and stirred at a ratio of 1:0.8 to obtain a second mixture; the obtained second mixture was calcined at a temperature of 600° C. for 2 hours at a low temperature.

[0095] Wash the roasted material in the second step, first dissolve the roasted material with water (the mass ratio of material to water is 1:2), and then put it into the reaction kettle wit...

Embodiment 3

[0098] A graphite purification process, comprising the steps of:

[0099] A natural graphite raw material with a carbon content of 90%-96% is selected, and the graphite raw material is stirred and mixed with 5% hydrochloric acid solution at a temperature of 80° C. for 3 hours. The first mixed material is obtained; the first mixed material obtained is washed to neutral in the first step to obtain the first intermediate material. Wherein, the number of times of washing in the first step is the same as in Example 1.

[0100] The obtained first intermediate material and the sodium hydroxide solution with a mass fraction of 50% were mixed and stirred at a ratio of 1:1 to obtain a second mixture; the obtained second mixture was calcined at a temperature of 500° C. for 6 hours at a low temperature.

[0101] Wash the roasted material in the second step, first dissolve the roasted material with water (the mass ratio of material to water is 1:1.5), and then put it into the reaction ket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com