Preparation method of 2-methyl-6-propionyl naphthalene

A technology of propionyl naphthalene and methyl naphthalene, applied in the field of coal chemical industry, can solve the problems of complex process and large investment, and achieve the effects of improving product yield, good shape selectivity, and enhanced synergy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

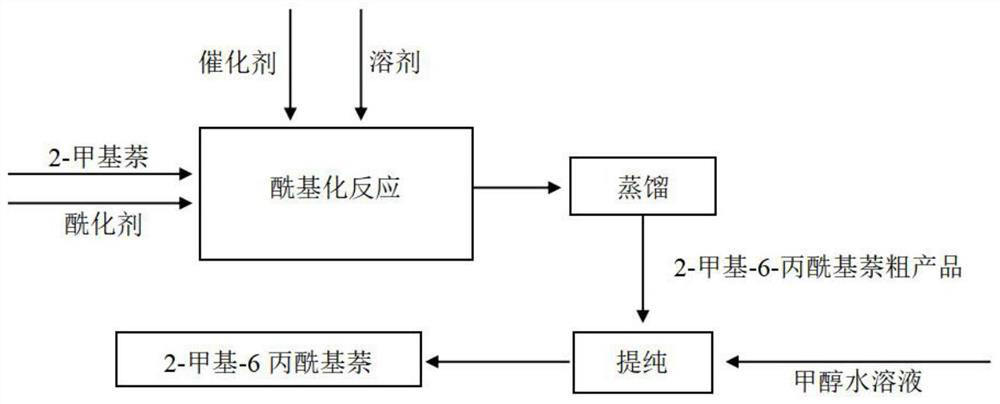

[0031] A preparation method of 2-methyl-6-propionyl naphthalene, comprising the steps of:

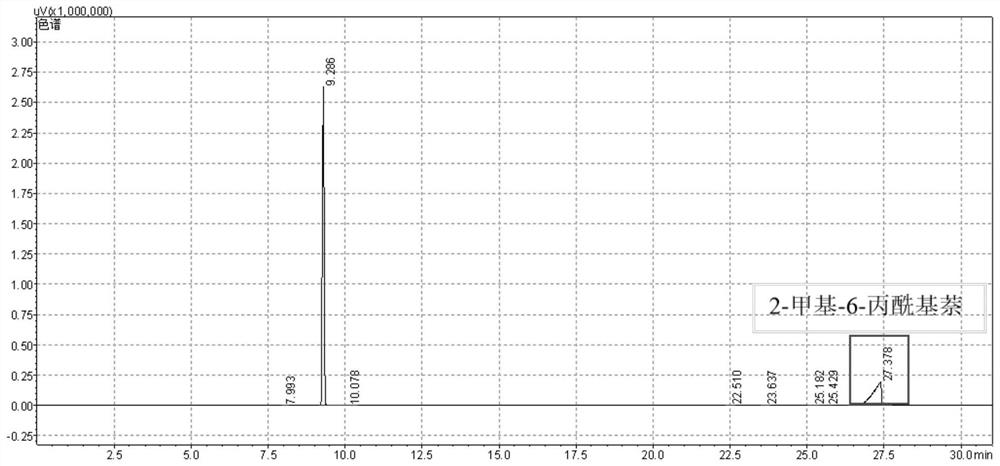

[0032] Weigh 180g of 2-methylnaphthalene, 326g of propionic anhydride, 350g of modified Hβ zeolite molecular sieve, and 100g of sulfolane into a three-necked flask, one of which is vertically connected to a condenser, one of which is inserted into a thermometer, and one of which is closed with a rubber stopper. Put the three-necked flask containing the raw materials into a metal bath with a stirring function, and carry out the acylation reaction at a speed of 600r / min and a temperature of 190°C. After the reaction has been carried out for 9 hours, stop stirring and keep warm, and wait for the three-necked flask to cool down. , take out a small amount of sample and carry out product analysis with gas chromatography, the transformation rate that analysis can obtain 2-methylnaphthalene: 78.9%. The catalyst was removed after the remaining samples were sucked through a Buchner funnel, and th...

Embodiment 2

[0034] A preparation method of 2-methyl-6-propionyl naphthalene, comprising the steps of:

[0035]Weigh 355g of 2-methylnaphthalene, 660g of propionic anhydride, 700g of modified Hβ zeolite molecular sieve, and 200g of sulfolane into a three-necked flask, one of which is vertically connected to a condenser tube, one of which is inserted into a thermometer, and one of which is closed with a rubber stopper. The flask was placed in a metal bath with a stirring function, and the acylation reaction was carried out at a speed of 600r / min and a temperature of 180°C. After the reaction was carried out for 10 hours, the stirring and heat preservation were stopped. After the three-necked flask was cooled, a small amount of samples were taken out and used for gas phase The product was analyzed by chromatography, and the conversion rate of 2-methylnaphthalene was analyzed to be 82.1%. The catalyst was removed after the remaining samples were sucked through a Buchner funnel, and the filtra...

Embodiment 3

[0037] A preparation method of 2-methyl-6-propionyl naphthalene, comprising the steps of:

[0038] Weigh 710g of 2-methylnaphthalene, 1320g of propionic anhydride, 350g of modified Hβ zeolite molecular sieve, and 200g of sulfolane into a three-necked flask, one of which is vertically connected to a condenser tube, one of which is inserted into a thermometer, and one of which is closed with a rubber stopper. The flask was placed in a metal bath with a stirring function, and the acylation reaction was carried out at a speed of 600r / min and a temperature of 200°C. After the reaction was carried out for 10 hours, the stirring and heat preservation were stopped. The product was analyzed by chromatography, and the conversion rate of 2-methylnaphthalene was analyzed to be 80.2%. The catalyst was removed after the remaining samples were sucked through a Buchner funnel, and the filtrate was distilled under reduced pressure at 180-210°C and 0.4-0.5kPa to obtain crude 2-methyl-6-propiony...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com