Water-based crack art coating and preparation method thereof

An art paint and crack technology, applied in the field of art paint, can solve the problems of large effect of process products, unfavorable large-area construction, and high construction difficulty, and achieve the effects of rich crack effect, easy construction and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

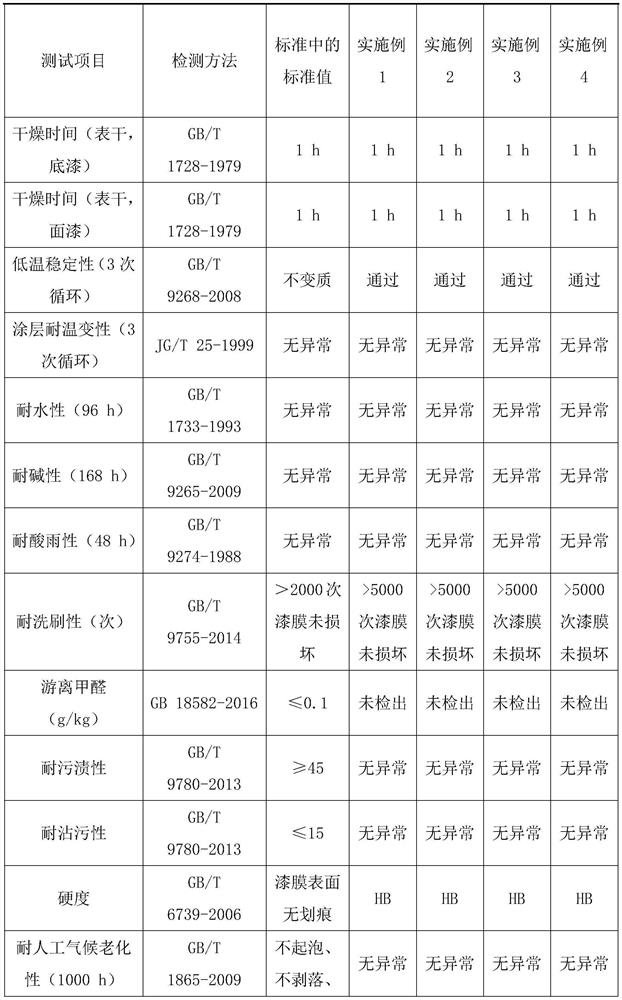

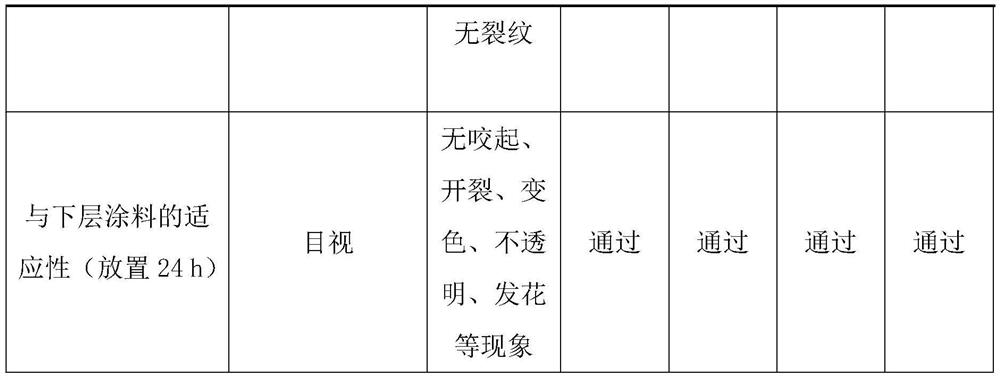

Embodiment 1

[0065] A water-based crack art paint of the present invention includes a crack primer and a crack topcoat that are used in combination, wherein the crack primer is mainly prepared from the following components in the following proportions by weight:

[0066] 7 parts water

[0067] 0.5 part of water-based dispersant

[0068] Aqueous wetting agent 0.5 part

[0069] 1.0 part of water-based defoamer

[0070] 1 part of white carbon black

[0071] 2 parts talcum powder

[0072] 5 servings of mica powder

[0073] 1 part of silane coupling agent

[0074] 70 parts of polyacrylic emulsion

[0075] 2 parts antifreeze

[0076] 5 parts of film-forming aids

[0077] 1 part preservative

[0078] 2 parts water-based color paste

[0079] 2 parts of water-based thickener;

[0080] The crack topcoat is mainly prepared from the following components in the following proportions by weight:

[0081] 9 parts water

[0082] 0.2 part of pH adjuster

[0083] 0.3 part of water-based dispers...

Embodiment 2

[0111] A water-based crack art paint of the present invention includes a crack primer and a crack topcoat that are used in combination, wherein the crack primer is mainly prepared from the following components in the following proportions by weight:

[0112] 10 parts water

[0113] 0.5 part of water-based dispersant

[0114] Aqueous wetting agent 0.5 part

[0115] 1.0 part of water-based defoamer

[0116] 2 parts of white carbon black

[0117] 3 parts talcum powder

[0118] 3 servings of mica powder

[0119] 2 parts of silane coupling agent

[0120] 65 parts of polyacrylic emulsion

[0121] 2 parts antifreeze

[0122] Coalescent agent 2 parts

[0123] 2 preservatives

[0124] 5 parts of water-based color paste

[0125] 2 parts of water-based thickener;

[0126] The crack topcoat is mainly prepared from the following components in the following proportions by weight:

[0127] 8 parts water

[0128] 0.5 part of pH adjuster

[0129] 0.5 part of water-based dispersan...

Embodiment 3

[0157] A water-based crack art paint of the present invention includes a crack primer and a crack topcoat that are used in combination, wherein the crack primer is mainly prepared from the following components in the following proportions by weight:

[0158] 6 parts water

[0159] 1.0 part of water-based dispersant

[0160] Aqueous wetting agent 1.0 part

[0161] 1.0 part of water-based defoamer

[0162] 3 parts of white carbon black

[0163] 2 parts talcum powder

[0164] 2 servings of mica powder

[0165] 2 parts of silane coupling agent

[0166] 65 parts of polyacrylic emulsion

[0167] 4 parts antifreeze

[0168] Coalescent agent 2 parts

[0169] 2 preservatives

[0170] 5 parts of water-based color paste

[0171] 4 parts of water-based thickener;

[0172] The crack topcoat is mainly prepared from the following components in the following proportions by weight:

[0173] 13 parts water

[0174] 0.5 part of pH adjuster

[0175] 1.0 part of water-based dispersan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com