Method for preparing bleaching powder slurry from waste incineration fly ash

A waste incineration fly ash and bleaching powder technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of inability to put into the bleaching powder production process, low slaked lime content, etc., achieve simple preparation method, improve conversion rate, and promote the reaction of calcium-based substances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

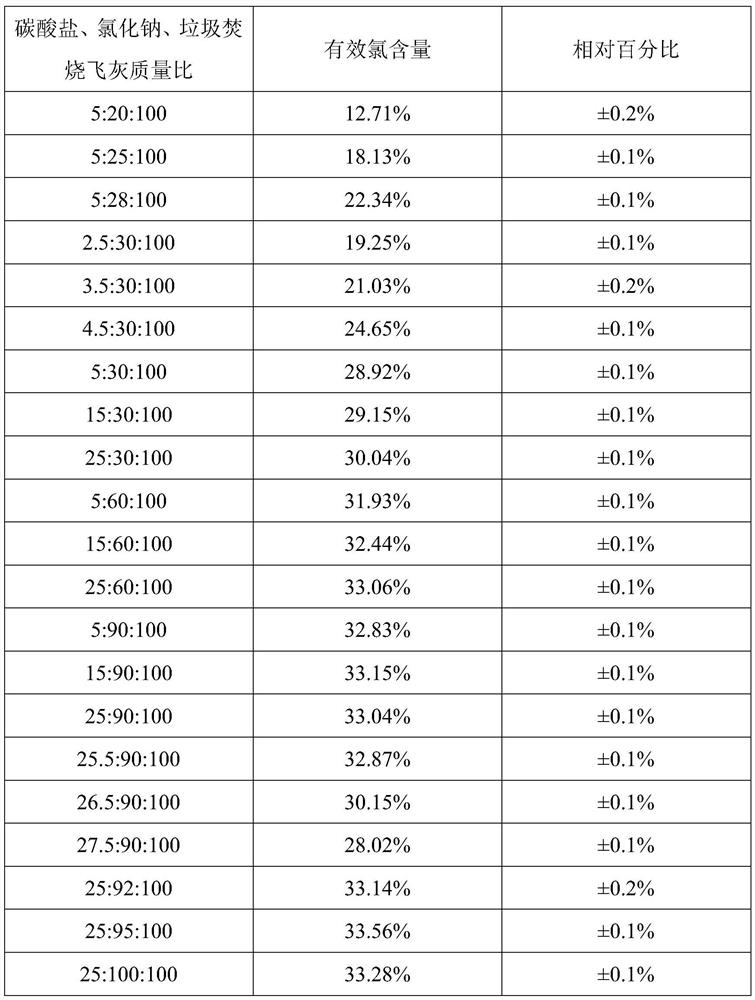

[0021] Effect of mass ratio of carbonate, sodium chloride, and waste incineration fly ash on available chlorine content of prepared bleaching slurry

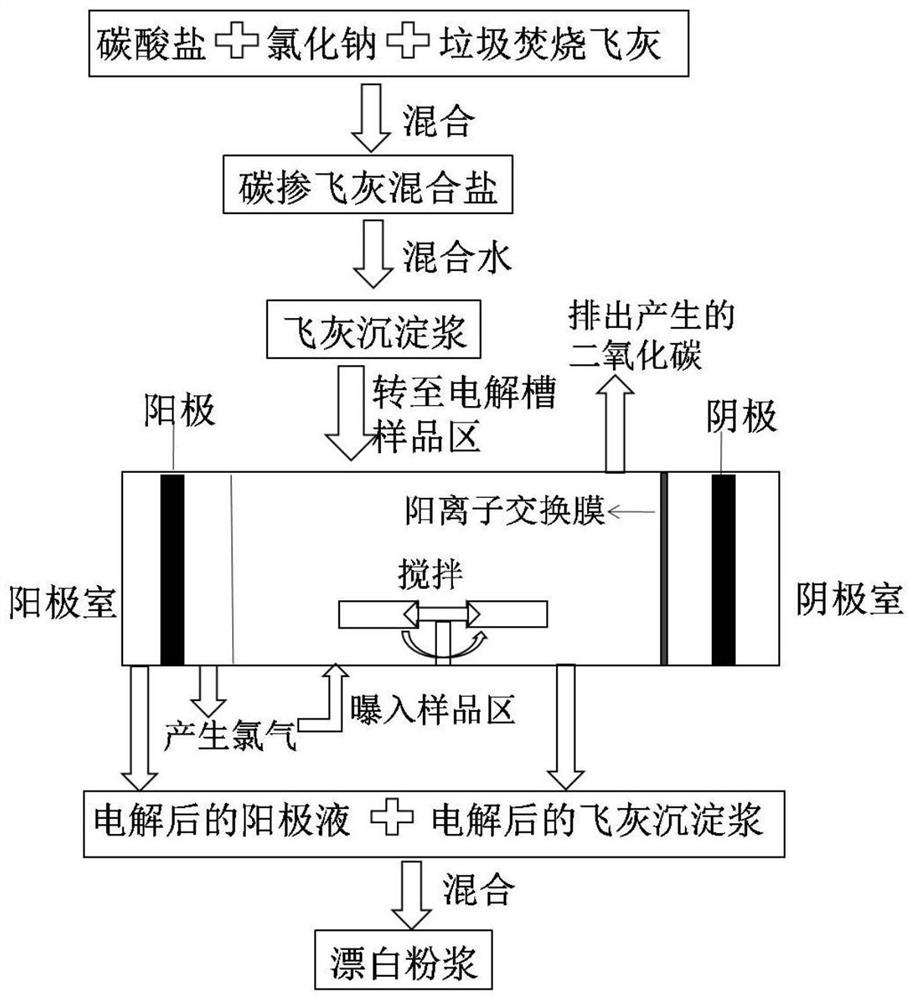

[0022] Preparation of bleaching slip: as in figure 1 As shown, according to the mass ratio 5:20:100, 5:25:100, 5:28:100, 2.5:30:100, 3.5:30:100, 4.5:30:100, 5:30:100, 15: 30:100, 25:30:100, 5:60:100, 15:60:100, 25:60:100, 5:90:100, 15:90:100, 25:90:100, 27.5:90: 100, 26.5:90:100, 25.5:90:100, 25:92:100, 25:95:100, 25:100:100 Weigh carbonate, sodium chloride, waste incineration fly ash respectively, mix and stir , to obtain carbon mixed with fly ash mixed salt, wherein the carbonate is sodium carbonate; according to the liquid-solid ratio 1mL:1g mixed water and carbon mixed with fly ash mixed salt, stirred for 20 minutes, to obtain fly ash precipitated slurry; import fly ash precipitated slurry In the sample area of the electrolytic cell, turn on the power, and conduct electrolytic treatment for 2 hours. Mix the electrolyzed ...

Embodiment 2

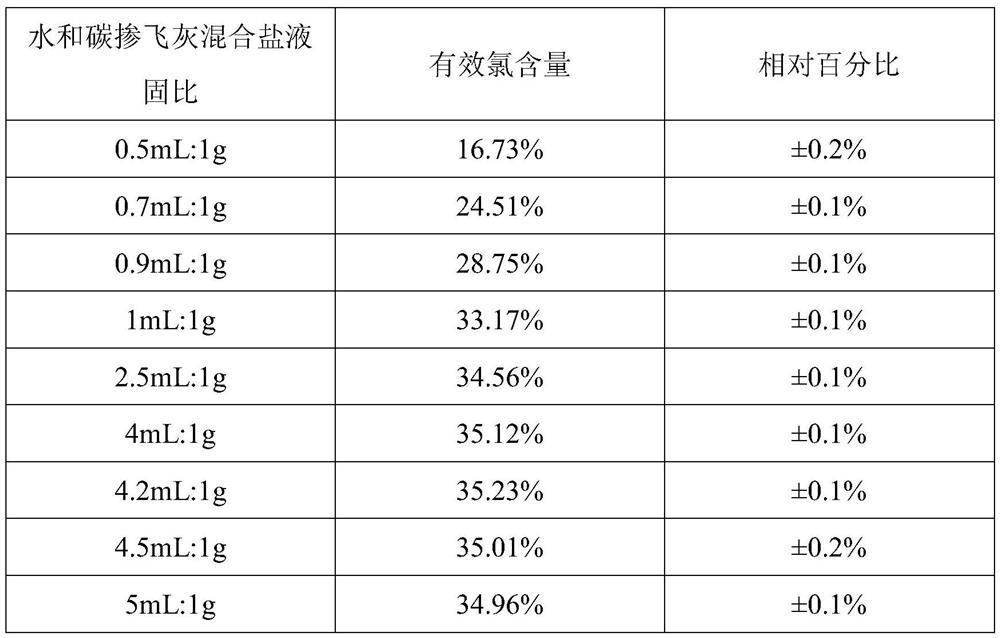

[0029] Effect of liquid-solid ratio of water and carbon mixed with fly ash on the available chlorine content of the prepared bleaching slurry

[0030] Preparation of bleaching slurry: Weigh carbonate, sodium chloride, waste incineration fly ash according to the mass ratio of 25:90:100, mix and stir to obtain carbon mixed with fly ash mixed salt, wherein carbonate is sodium carbonate; Solid ratio 0.5mL:1g, 0.7mL:1g, 0.9mL:1g, 1mL:1g, 2.5mL:1g, 4mL:1g, 4.2mL:1g, 4.5mL:1g, 5mL:1g mixed with water and carbon-doped fly ash Mix the salt and stir for 40 minutes to obtain the fly ash sedimentation slurry; introduce the fly ash sedimentation slurry into the sample area of the electrolytic cell, turn on the power, turn on the power supply, and electrolyze for 4 hours, and mix the electrolyzed electrolyzer anolyte with the electrolyzed sample The fly ash sedimentation slurry in the sample area is mixed and stirred evenly to obtain a bleached slurry. In the process of turning on the pow...

Embodiment 3

[0036] Influence of Power On Time on Available Chlorine Content of Prepared Bleaching Slurry

[0037] Preparation of bleaching slurry: Weigh carbonate, sodium chloride, waste incineration fly ash according to the mass ratio of 5:30:100, mix and stir to obtain carbon mixed with fly ash mixed salt, wherein carbonate is sodium carbonate; Solid ratio 4mL: 1g mixed with water and carbon mixed with fly ash mixed salt, stirred for 60 minutes to obtain fly ash sedimentation slurry; import the fly ash sedimentation slurry into the sample area of the electrolytic cell, turn on the power, and electrolyze for 0.5 hours, 1 hour, 1.5 hours respectively hour, 2 hours, 4 hours, 6 hours, 6.5 hours, 7 hours, 7.5 hours, mix the anolyte of the electrolytic cell after electrolysis with the fly ash sedimentation slurry in the sample area after electrolysis, and stir evenly to obtain bleaching slurry. During the power-on process, the chlorine gas generated in the anode chamber of the electrolytic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com