Linear light sweeping module for developing glass and liquid crystal whole film image detector

An optical module, line scan technology, applied in the direction of using optical devices, optical testing flaws/defects, measuring devices, etc., can solve the problems of poor detection effect and inconspicuous imaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

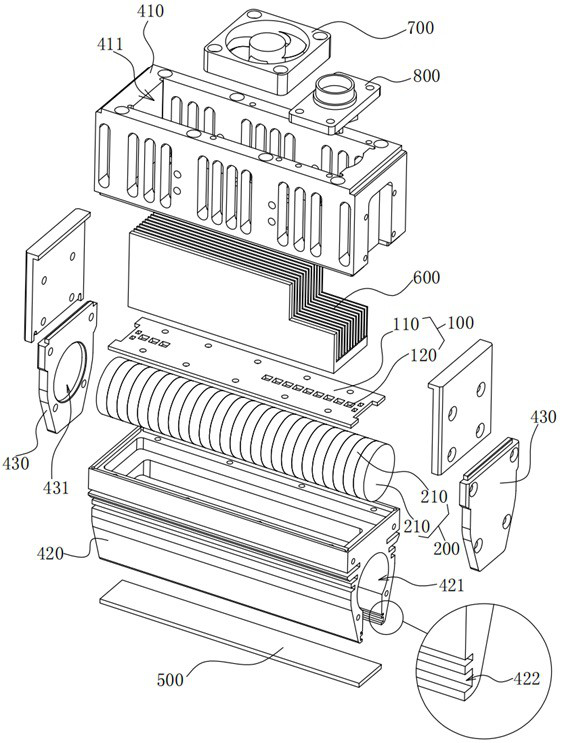

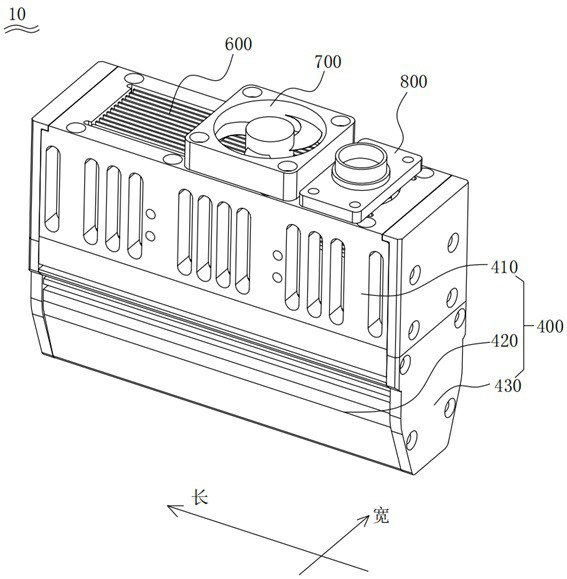

[0041] Such as figure 1 , figure 2 As shown, this embodiment discloses a line-scanning light module 10 for developing glass, which is used to detect lines on the developing glass, which includes a light source part 100, a light guide part 200, and a light-shielding sheet (not marked in the figure) ). For the convenience of structural description, take the projected outline of the line-sweeping optical module 10 on the horizontal plane as a rectangle as an example, the long side direction of the rectangle is the length direction, and the short side direction is the width direction. In this embodiment, both the length direction and the width direction are used As a benchmark, the structural description is carried out. The light source part 100 in this embodiment is extended along the longitudinal direction, and the light source part 100 includes a plurality of light guide round tables 210, and the plurality of light guide round tables 210 are arranged corresponding to the plu...

Embodiment 2

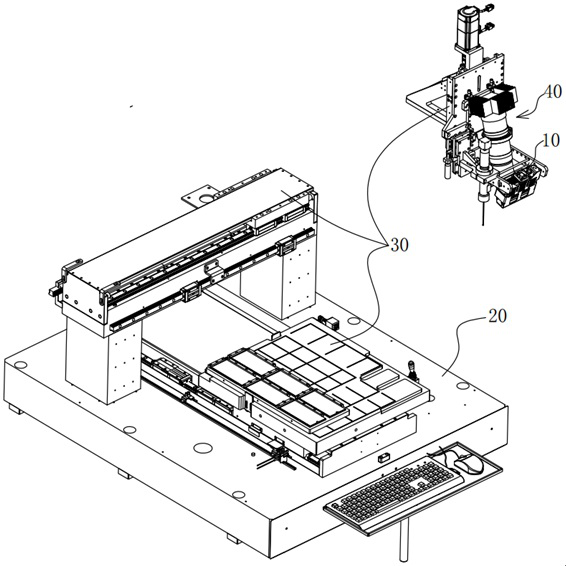

[0057] Such as image 3 , Figure 4 As shown, based on the same idea, the present invention also proposes a liquid crystal full-film image inspection machine, which includes: a machine platform 20, an XYZ direction moving assembly 30, a camera assembly 40, and the line-scanning optical module in Embodiment 1 10. The machine table 20 is arranged horizontally, the XYZ direction moving assembly 30 is arranged on the machine table 20, the camera assembly 40 is arranged on the XYZ direction moving assembly 30; the line scanning optical module 10 is detachable It is arranged on the moving component 30 in the XYZ direction. The developing glass to be inspected is placed horizontally on the machine platform 20, and the camera assembly 40 and the line scanning module are moved in the X direction, the Y direction, and the Z direction through the XYZ direction moving assembly 30 to realize the camera assembly 40 and the line scanning module. The module scans the developing glass to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com