Second-generation high-temperature superconducting strip closed coil and preparation method thereof

A high-temperature superconducting tape, closed coil technology, applied in superconducting magnet/coil, coil manufacturing, inductor/transformer/magnet manufacturing, etc., can solve the problem of difficult face-to-face connection of REBCO superconducting layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

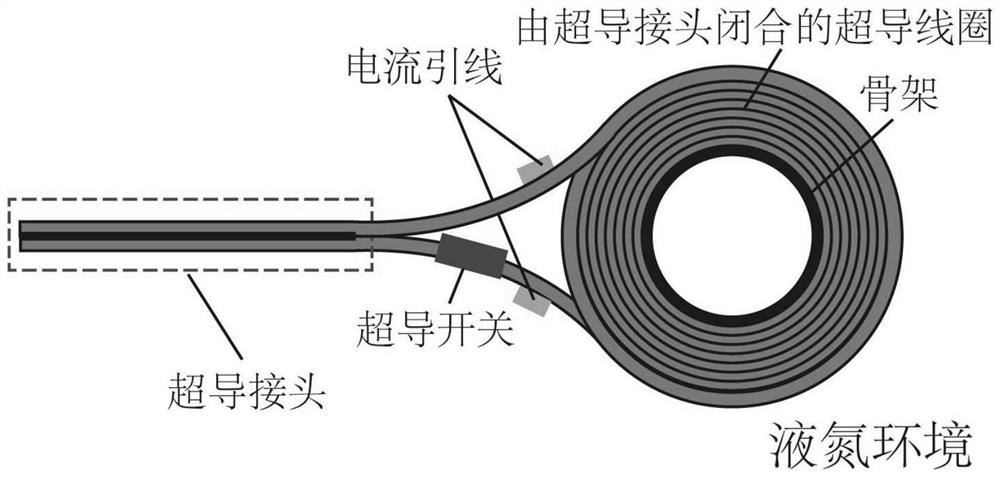

[0036] In the present invention, the preparation method comprises the following steps:

[0037] (1) Wrap the second-generation high-temperature superconducting strip with insulating material, wind the second-generation high-temperature superconducting strip wrapped with insulating material into a coil, and leave both ends of the strip as joints to be connected;

[0038] (2) exposing the superconducting layer of the joint to be connected, and performing fusion diffusion welding after overlapping the superconducting layer of the joint to obtain a coil with a welded joint;

[0039] (3) heat-treating the welded joint in an oxygen-containing atmosphere to obtain a preliminary closed coil;

[0040] (4) Copper-clad treatment is performed on the welding joint of the preliminary closed coil, and the coil after copper-clad treatment is impregnated with epoxy resin, and after curing, a second-generation high-temperature superconducting tape closed coil is obtained.

[0041] The inventio...

Embodiment 1

[0062] A method for preparing a second-generation high-temperature superconducting tape closed coil, comprising the following steps:

[0063] (1) Evenly wrap insulating paper on the surface of the second-generation high-temperature superconducting strip and wind it on the skeleton;

[0064] (2) Use silver etchant Silver Etchant TFS to etch the silver layer at both ends of the second-generation high-temperature superconducting tape wound on the skeleton, so that the YBCO superconducting layer is exposed.

[0065] (3) After lapping the exposed superconducting layers, perform fusion diffusion welding on the overlapping area under a vacuum atmosphere of 25 Pa, specifically applying a pressure of 20 MPa, and raising the temperature of the overlapping area to 820°C and keeping it warm for 20 minutes, Make the overlapping area form a joint.

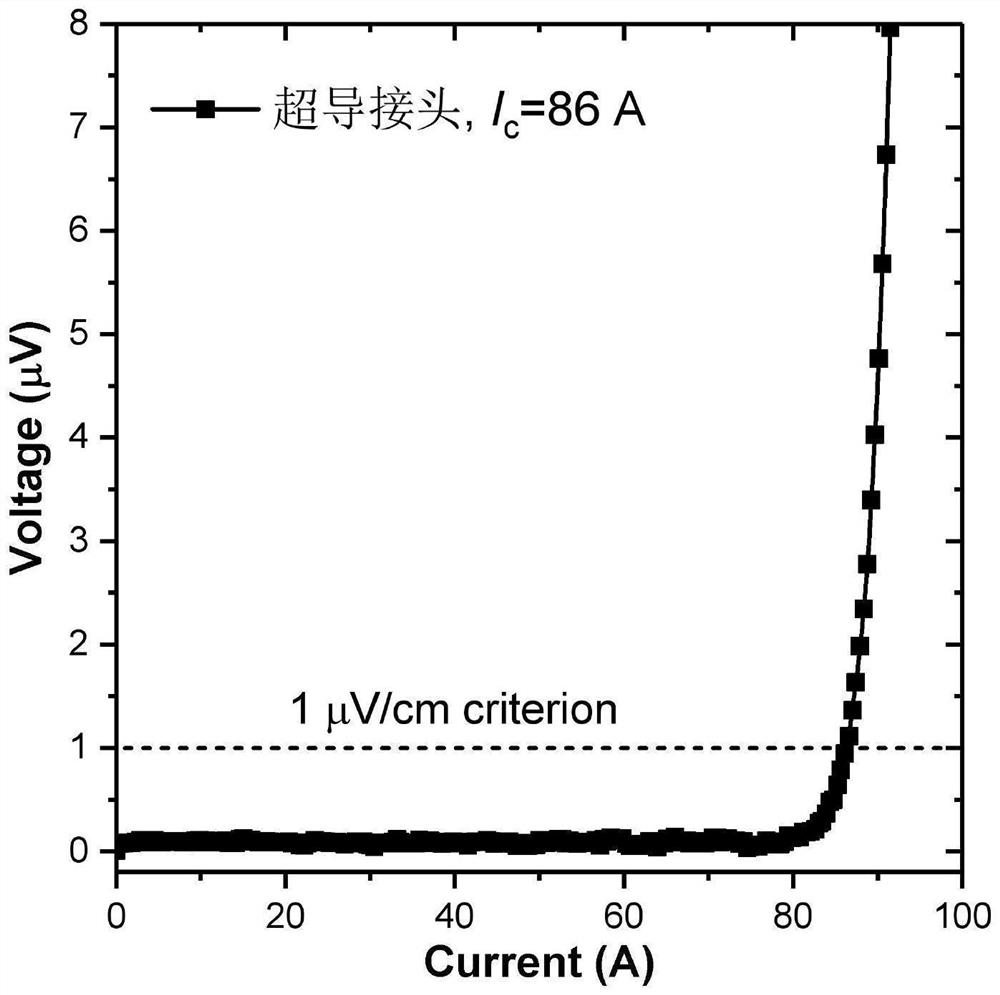

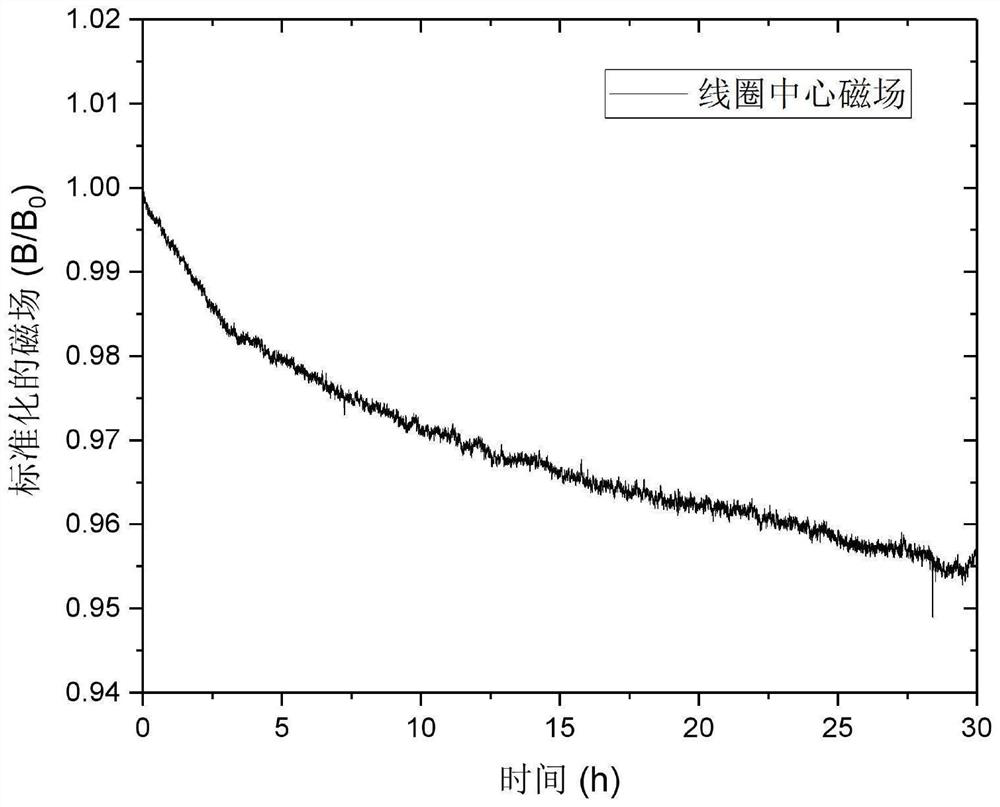

[0066] (4) The coil was annealed in a pure oxygen environment at 500°C for 60 hours, so that the connected YBCO superconducting layer recovere...

Embodiment 2

[0072] A method for preparing a second-generation high-temperature superconducting tape closed coil, comprising the following steps:

[0073] (1) Evenly wrap insulating paper on the surface of the second-generation high-temperature superconducting strip and wind it on the skeleton;

[0074] (2) Use silver etchant Silver Etchant TFS to etch the silver layer at both ends of the second-generation high-temperature superconducting tape wound on the skeleton, so that the YBCO superconducting layer is exposed.

[0075] (3) After lapping the exposed superconducting layers, perform fusion diffusion welding on the overlapping area under a vacuum atmosphere of 5Pa, specifically applying a pressure of 10MPa, and raising the temperature of the overlapping area to 800°C and keeping it warm for 30min, Make the overlapping area form a joint.

[0076] (4) The coil was annealed in a pure oxygen environment at 500°C for 150 hours, so that the connected YBCO superconducting layer recovered its s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com