Method for recovering CO in low-temperature methanol washing tail gas with low energy consumption

A technology of low-temperature methanol washing and low energy consumption, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of large flash gas volume, high energy consumption, and high compressor power, and achieve environmental protection and low energy consumption. , The effect of reducing the energy consumption of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

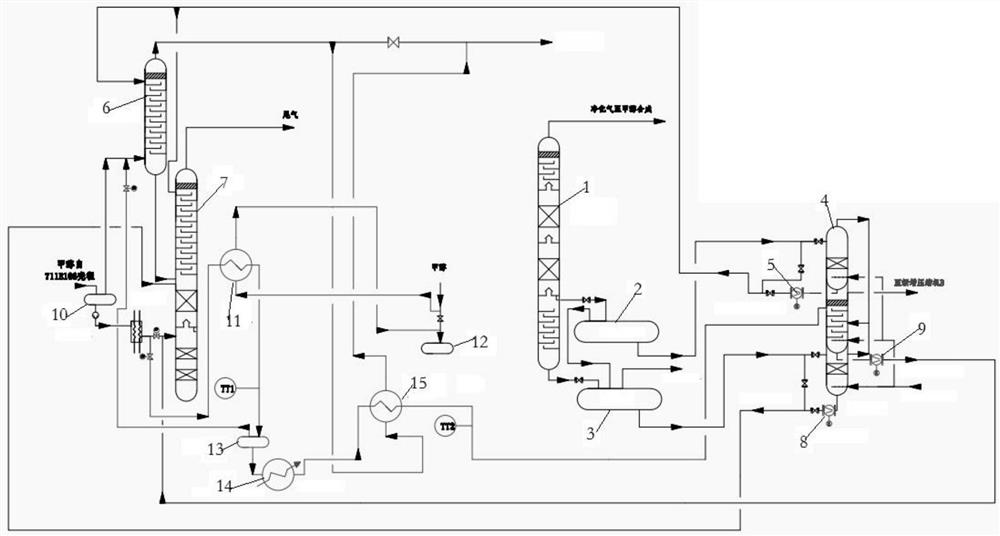

[0025] Such as figure 1 As shown, for the 180wt / a coal-to-methanol project, the shift gas enters the 8.7MPa low-temperature methanol washing system at 7.6MPa(G) and 40°C, and enters the bottom of methanol washing tower 1 after water capture, precooling, and liquid separation , in reverse contact with lean methanol at -62°C from the top of methanol scrubber 1 to remove H from the shift gas, respectively 2 S, COS, CO 2 and other acidic media, the qualified purified gas is discharged from the top of the methanol washing tower 1, and the H 2 S, COS, CO 2 There is a huge difference in solubility in lean methanol, the carbon-rich methanol from the bottom of the upper column of methanol scrubber 1 and the sulfur-rich methanol from the bottom of the lower column of methanol scrubber 1 are cooled and sent to the first flash tank 2 and the second flash tank respectively In the steam tank 3, the pressure is reduced to 1.6MPa at this time to carry out the first-stage medium-pressure fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com