Self-cleaning type cooling tank for high polymer material production

A polymer material and self-cleaning technology, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as inability to cool liquids to assist cooling, large cooling dead angles, and inability to clean polymer materials. , to achieve the effect of improving convenience, rapid cooling and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

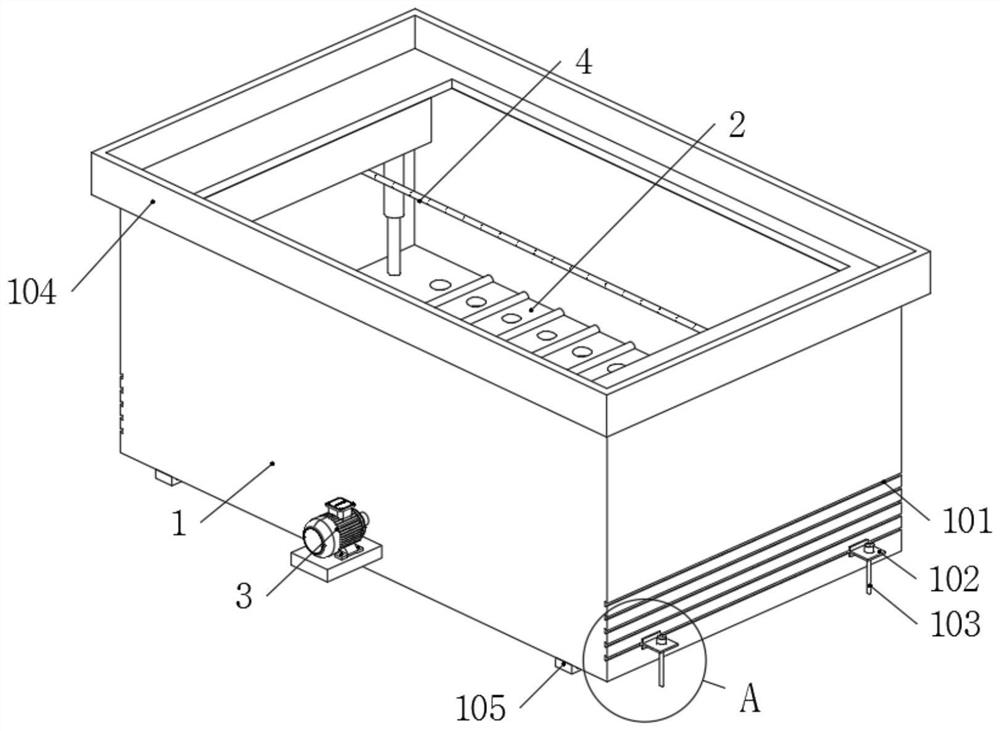

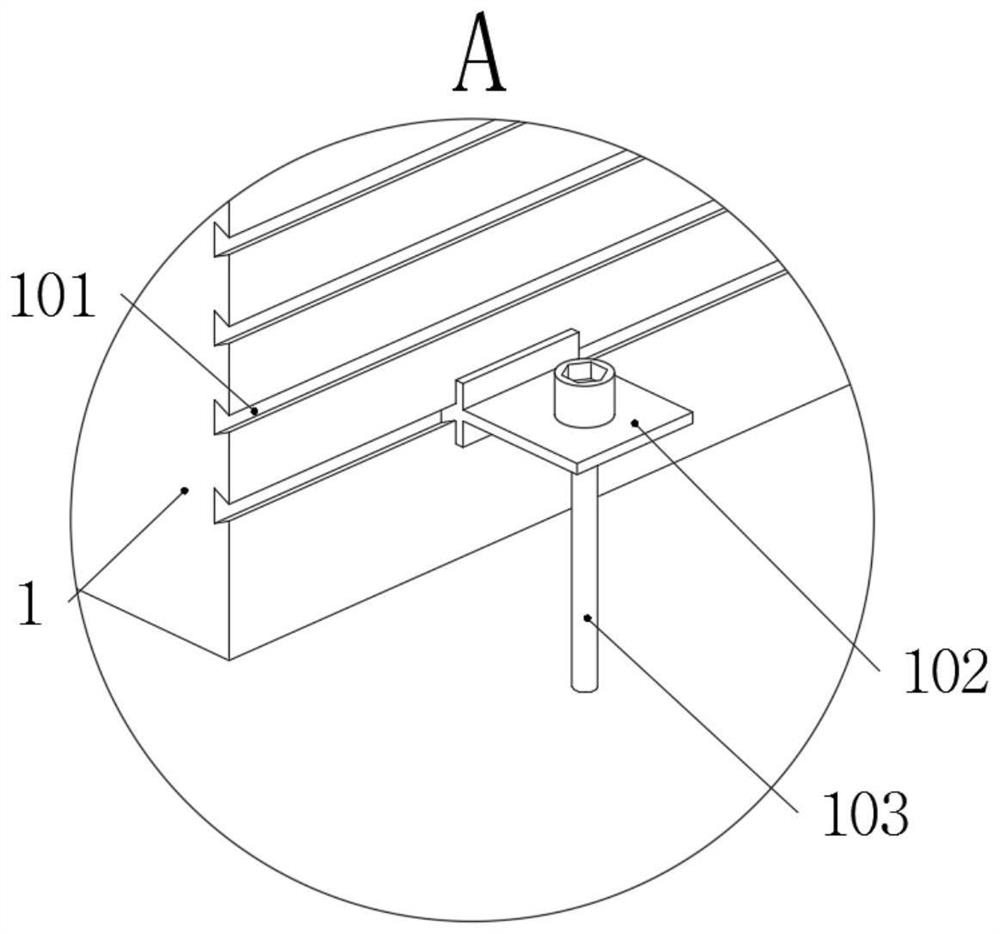

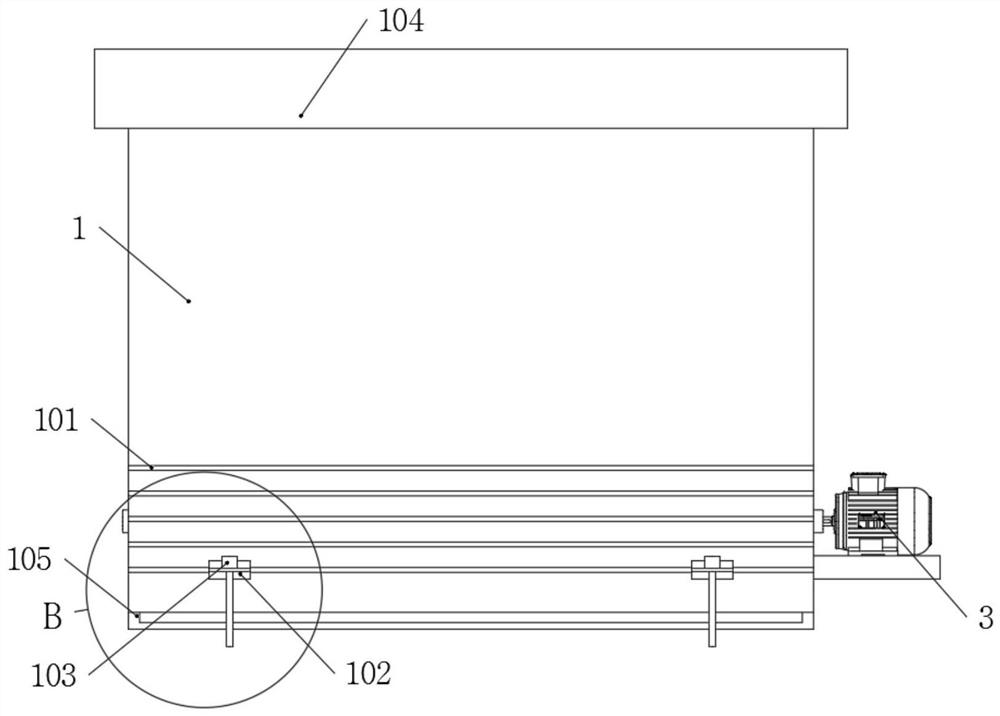

[0037] Example: Please refer to Figure 1 to Figure 8 :

[0038] The present invention proposes a self-cleaning cooling tank for the production of polymer materials, including: a box body 1, a placement part 2, an auxiliary part 3 and a heat dissipation part 4;

[0039] The box body 1 is placed on the workbench;

[0040] The placing part 2 is composed of a mounting base 201, an elastic telescopic rod 202, a placing plate 203, a through hole 204 and a protrusion 205, and there are two mounting bases 201, and the two mounting bases 201 are fixedly connected to the box body by bolts. 1 on the inner wall;

[0041] The auxiliary part 3 is composed of a rotating shaft 301, an impeller 302 and a driving motor 303, and the rotating shaft 301 is rotatably connected to the box body 1;

[0042] The heat dissipation part 4 is composed of a piston bottle 401 , a connecting pipe 402 , a spray pipe 403 and a spray hole 404 , and there are two piston bottles 401 , and the two piston bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com