Dilute sulfuric acid concentration method in chlorine gas drying process

A dilute sulfuric acid, drying technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of concentrated sulfuric acid acid mist, low production safety, pollution, etc., and achieve low cost, high safety, and easy transportation little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

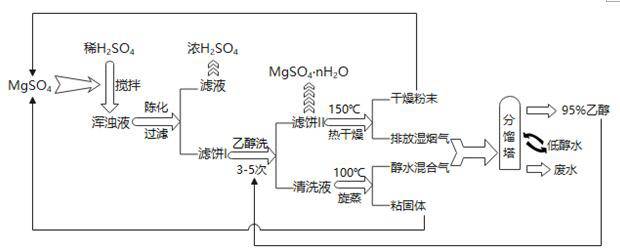

[0025] Refer figure 1 , A dilute sulfate in a chlorine drying process, including the following steps:

[0026] 1) Plus Hi per ton 2 SO 4 Mix 0.25 tons of MGSO 4 , Strongly stirring to get turbid, turbid of 20-30 min, placed in a concentrated sulfuric acid filter, pressurized and filtered, the resulting filtrate is thick h 2 SO 4 , Return to the chlorine drying process, the resulting filter cake I, spare;

[0027] 2) In the concentrated sulfuric acid filter, ethanol is added, and the filter cake I is cleaned 3-5 times, and the crystalline filter cake II is obtained, that is, MgSO. 4 · NH 2 O Crystallization, until there is no liquid droplets in the filter, the resulting cleaning liquid, spare;

[0028] 3) Place the filter cake II in the digester, heat dried at 150 ° C, steaming the wet pipe gas, the resulting dry powder, spare;

[0029] 4) Add the cleaning solution to the oil bath cent steam, steam at 100 ° C, steamed the alcohol water mixture, the resulting viscosity, spare of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com