Purification method of 2-chloro-2-oxo-1, 3, 2-dioxaphospholane

A dioxaphospholane and purification method technology, which is applied in the direction of separation methods, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc., can solve the problems of large COP loss, easy decomposition, and high boiling point , to achieve the effect of improving equipment life, avoiding pyrolysis, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Get crude product COP altogether 100g, wherein impurity content is 10g, crude COP is purified, and purification process comprises the following steps:

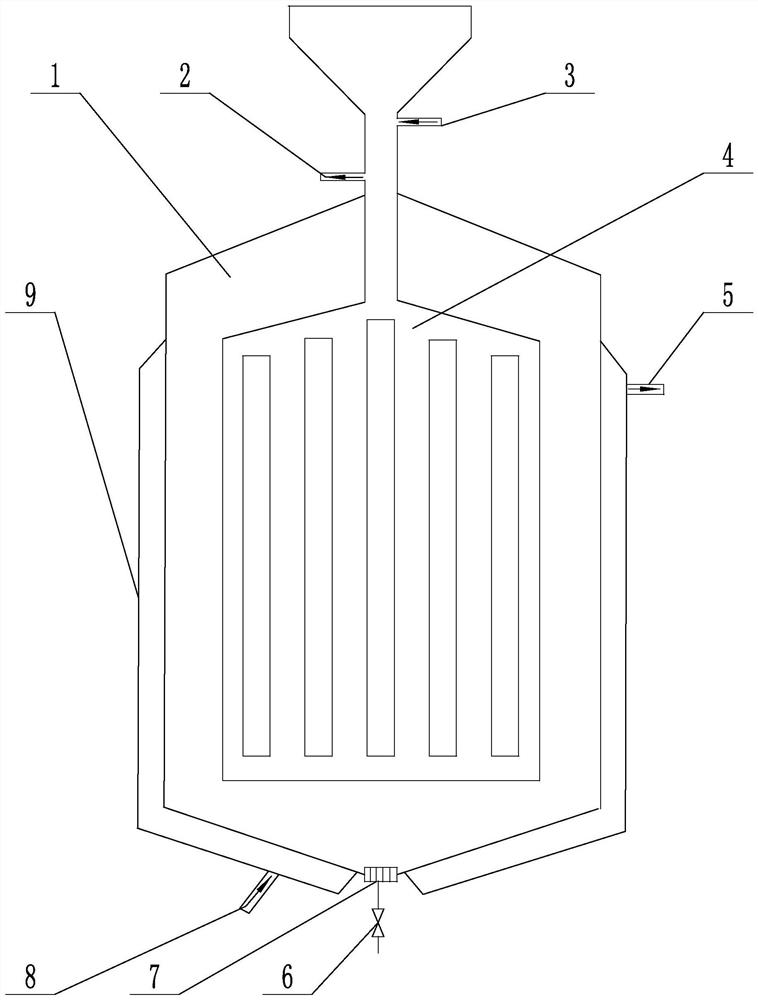

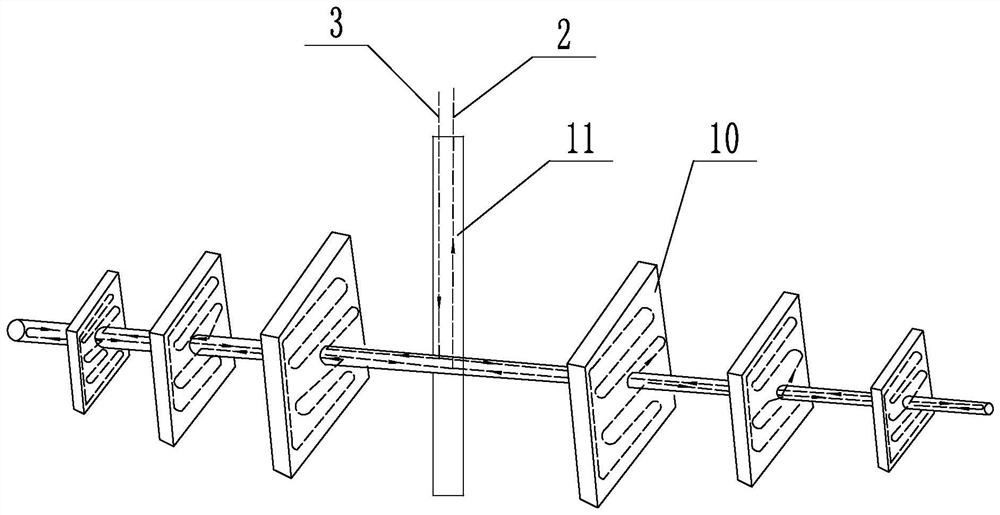

[0040] (1) Under the protection of nitrogen, pass the crude product COP into the melting crystallizer, pass into the cooling water in the hollow fin type stirring, pass into the cooling water in the jacket of the melting crystallizer, control the temperature of the cooling water at 5 °C per hour Cool down to -25°C at a speed of 30 r / min while stirring slowly for 4 hours;

[0041] (2) After the crystallization of the crude COP is complete, open the discharge valve with the tetrafluoro filter plate at the bottom, let off the uncrystallized toluene, then close the bottom valve, and set the temperature of the cooling water in the jacket of the melting crystallizer and the hollow stirring at a rate of each Slowly heat up to 0°C at a speed of 0.5°C per hour, at this time, the crystallized crude COP begins to sweat once, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com