Dual-crosslinked cellulose-based hydrogel prepared from cold plasma and preparation method and application of dual-crosslinked cellulose-based hydrogel

A cold plasma, double cross-linking technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of toxic chemical reagents, pollute the environment, complex processes, etc. Adsorption effect, the effect of improving the adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

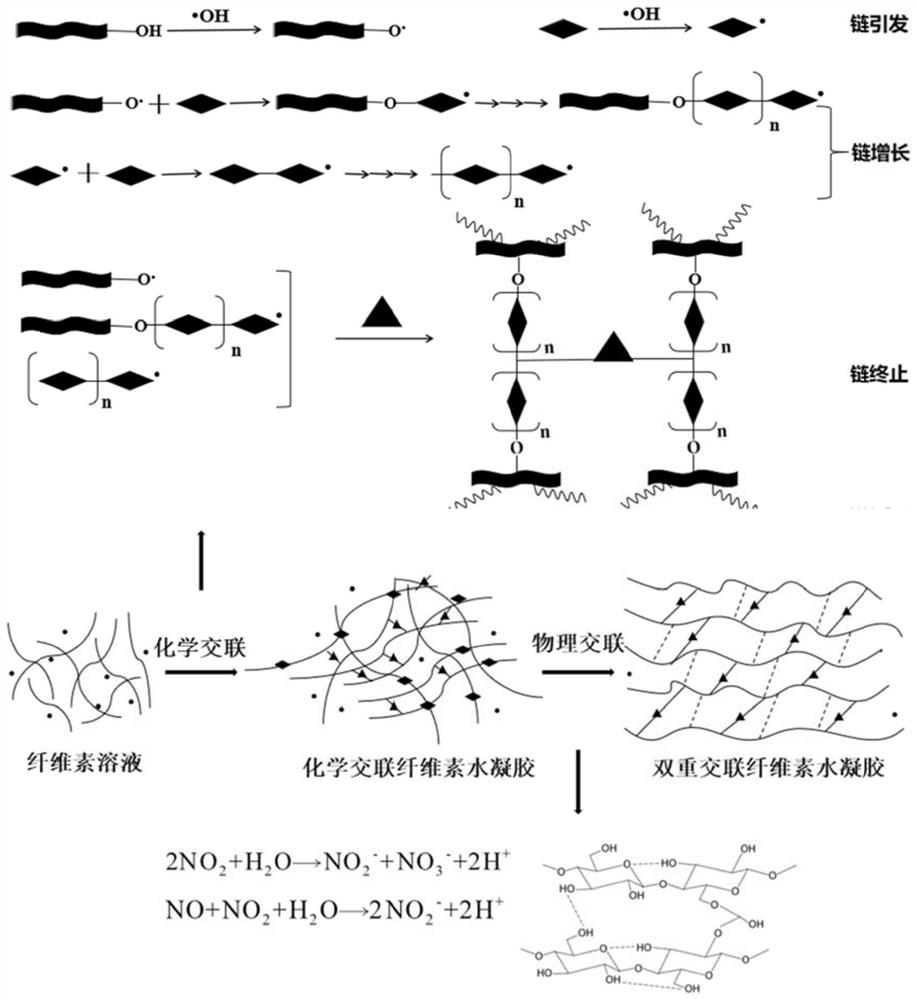

Method used

Image

Examples

Embodiment 1

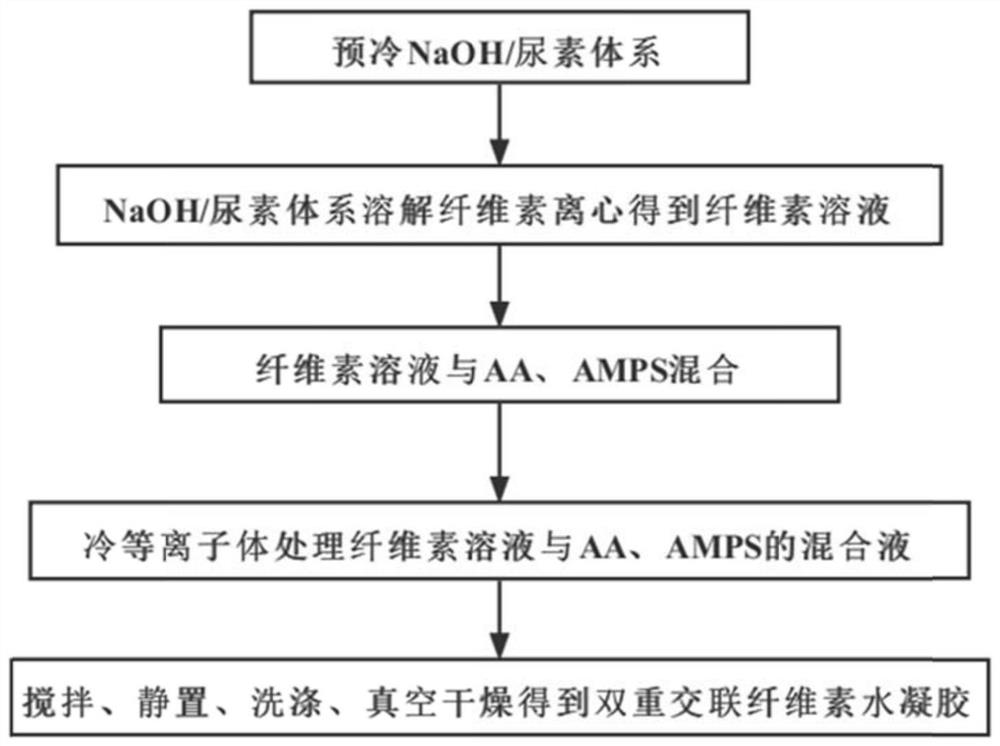

[0040] The method for preparing double cross-linked cellulose-based hydrogel based on cold plasma and its application in this embodiment are as follows:

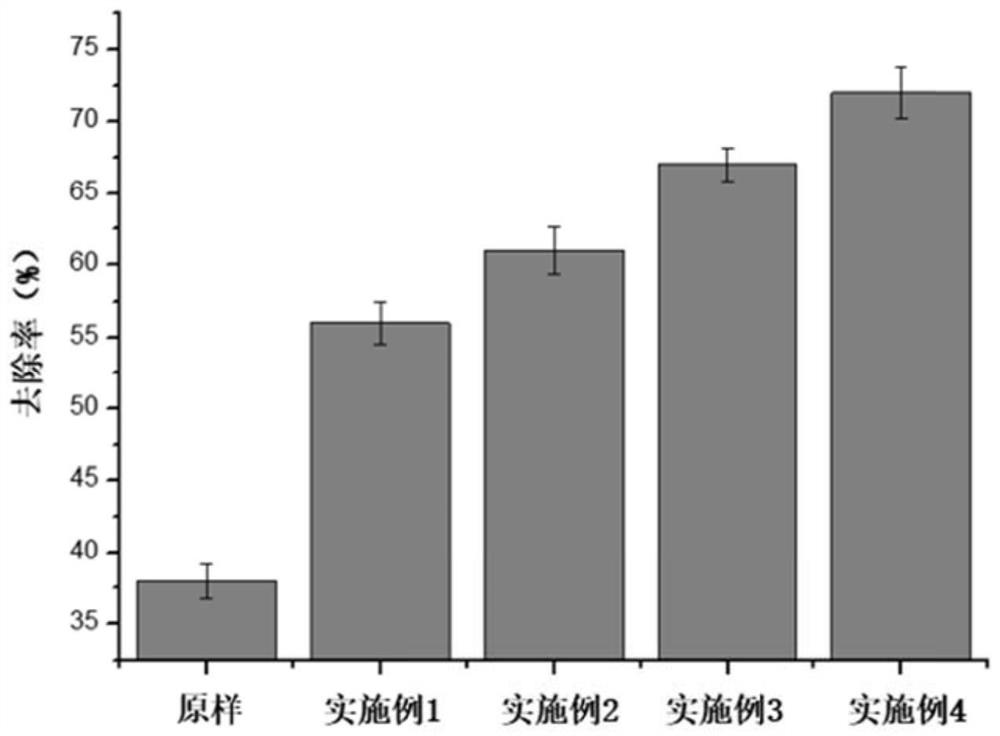

[0041]Weigh 7g of NaOH and 12g of urea, dissolve them in 81g of deionized water, and freeze at -12°C for 1 hour to obtain a NaOH / urea system. Weigh 2 g of dried pineapple pomace cellulose and place it in a NaOH / urea system, stir and disperse until the cellulose is completely dissolved, and centrifuge at 5000 r / min for 5 min to obtain a cellulose solution. Weigh 6g of acrylic acid (AA) and 0.6g of 2-acrylamide-2-methylpropane sulfonic acid (AMPS) and add it to the cellulose solution to perform cold plasma treatment (voltage is 100kV, frequency is controlled at 50Hz, power is controlled at 45kW) , the treatment time was 15 min, the mixture was uniformly stirred, and allowed to stand at room temperature for 24 h. The product was washed with water and acetone, and vacuum dried to constant weight to obtain a double cross-linked c...

Embodiment 2

[0043] Weigh 7g of NaOH and 12g of urea, dissolve them in 81g of deionized water, and freeze at -12°C for 1 hour to obtain a NaOH / urea system. Weigh 2 g of dried pineapple pomace cellulose and place it in a NaOH / urea system, stir and disperse until the cellulose is completely dissolved, and centrifuge at 5000 r / min for 5 min to obtain a cellulose solution. Weigh 6g of acrylic acid (AA) and 0.6g of 2-acrylamide-2-methylpropanesulfonic acid (AMPS) and add it to the cellulose solution and then carry out cold plasma treatment (voltage is 120kV, frequency is controlled at 50Hz, power is controlled at 45kW) , the treatment time was 30 min, the mixture was uniformly stirred, and allowed to stand at room temperature for 24 h. The product was washed with water and acetone, and dried in vacuum to constant weight to obtain a double-crosslinked cellulose hydrogel. The prepared cellulose-based hydrogel was put into Zn with a concentration of 600 mg / L and a pH of 6.5. 2+ , Cd 2+ and Cr 3...

Embodiment 3

[0045] Weigh 7g of NaOH and 12g of urea, dissolve them in 81g of deionized water, and freeze at -12°C for 1 hour to obtain a NaOH / urea system. Weigh 2 g of dried pineapple pomace cellulose and place it in a NaOH / urea system, stir and disperse until the cellulose is completely dissolved, and centrifuge at 5000 r / min for 5 min to obtain a cellulose solution. Weigh 6g of acrylic acid (AA) and 0.6g of 2-acrylamide-2-methylpropanesulfonic acid (AMPS) and add it to the cellulose solution and then carry out cold plasma treatment (voltage is 150kV, frequency is controlled at 50Hz, power is controlled at 45kW) , the treatment time was 45 min, the mixture was uniformly stirred, and allowed to stand at room temperature for 24 h. The product was washed with water and acetone, and dried in vacuum to constant weight to obtain a double-crosslinked cellulose hydrogel. The prepared cellulose-based hydrogel was put into Zn with a concentration of 800 mg / L and a pH of 6. 2+ , Cd 2+ and Cr 3+ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com