Graphene transparent conductive film and preparation method and application thereof

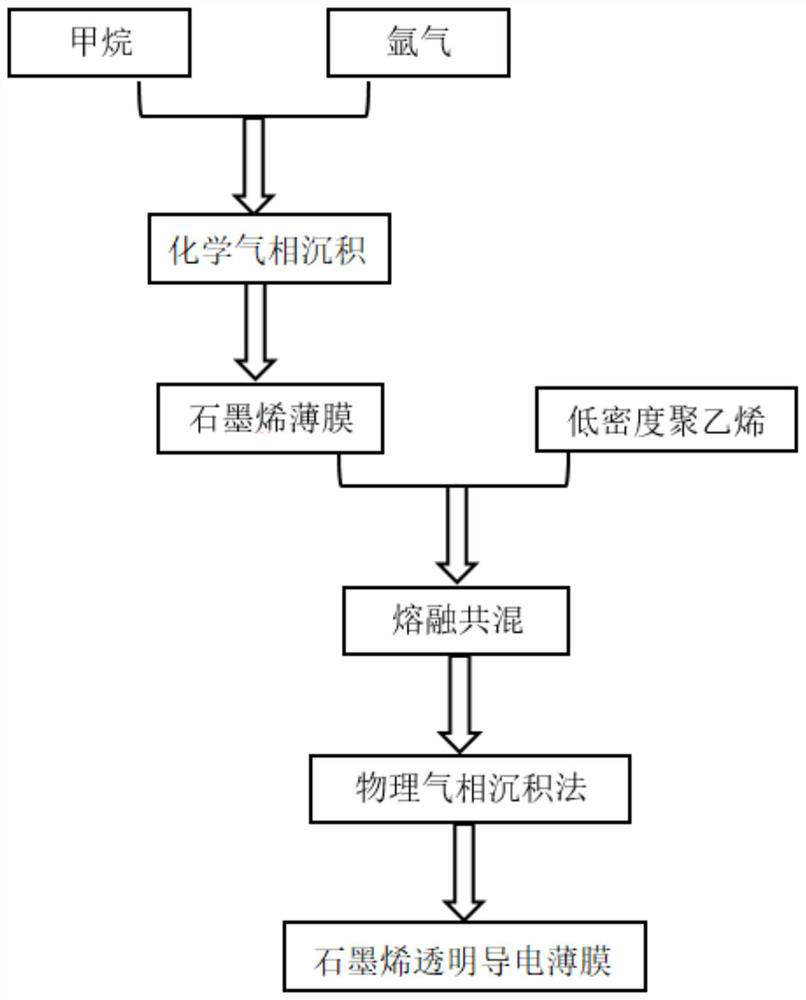

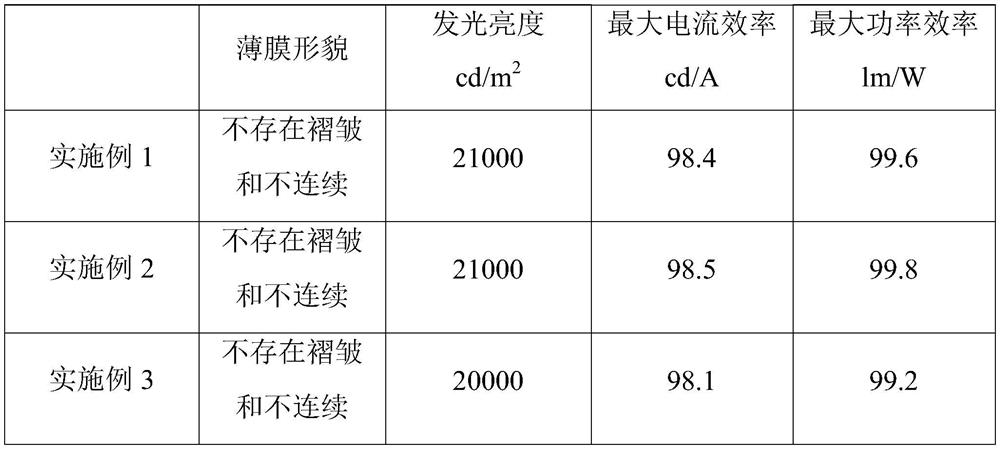

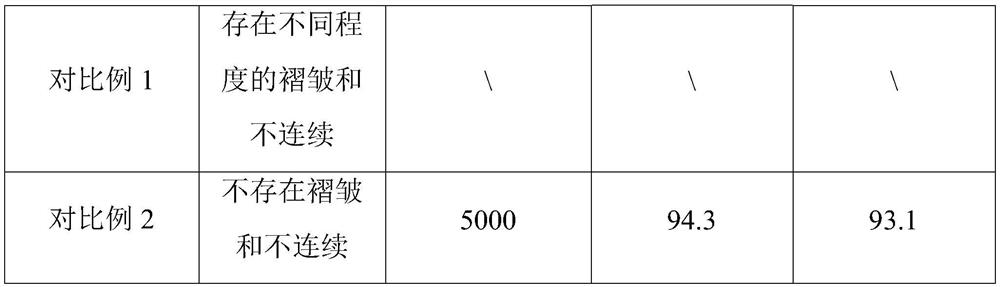

A transparent conductive film, graphene film technology, applied in the direction of the conductive layer on the insulating carrier, etc., can solve the problems of wrinkles and discontinuities of the conductive film, and achieve the effect of excellent performance, high conductivity, and smooth refresh effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of graphene transparent conductive film, comprising the following steps:

[0028] a. Open the vacuum valve of the reaction furnace, evacuate the reaction furnace, and raise the temperature in the reaction furnace to 900°C, then feed methane and argon (the volume ratio of methane and argon is 1:3), and adjust the ventilation valve Let methane and argon enter the reaction furnace evenly, carry out the chemical vapor deposition reaction for 10 minutes, and carbon atoms are deposited on the single crystal silicon substrate under the argon medium to form a graphene film;

[0029] b. The reaction furnace is evacuated, and the temperature in the reaction furnace is adjusted to 280° C., and low-density polyethylene is introduced to make the low-density polyethylene (density 0.90 g / cm 3 ) carry out fusion reaction 2min (mass ratio of graphene film and low-density polyethylene is 100:1) with above-mentioned graphene film in reaction furnace, realize melt blen...

Embodiment 2

[0033] A preparation method of graphene transparent conductive film, comprising the following steps:

[0034] a. Open the vacuum valve of the reaction furnace, evacuate the reaction furnace, and raise the temperature in the reaction furnace to 920°C, then feed methane and argon (the volume ratio of methane and argon is 2:3), and adjust the ventilation valve Let methane and argon enter the reaction furnace uniformly, carry out the chemical vapor deposition reaction for 12 minutes, and carbon atoms are deposited on the single crystal silicon substrate under the argon medium to form a graphene film;

[0035] b. The reaction furnace is evacuated, and the temperature in the reaction furnace is adjusted to 290°C, and low-density polyethylene is introduced to make the low-density polyethylene (density 0.93g / cm 3 ) carry out fusion reaction 3min (mass ratio of graphene film and low-density polyethylene is 100:1.2) with above-mentioned graphene film in reaction furnace, realize melt bl...

Embodiment 3

[0038] A preparation method of graphene transparent conductive film, comprising the following steps:

[0039] a. Open the vacuum valve of the reaction furnace, evacuate the reaction furnace, and raise the temperature in the reaction furnace to 950°C, then feed methane and argon (the volume ratio of methane and argon is 2:5), and adjust the ventilation valve Let methane and argon enter the reaction furnace uniformly, carry out the chemical vapor deposition reaction for 15 minutes, and carbon atoms are deposited on the single crystal silicon substrate under the argon medium to form a graphene film;

[0040] b. The reaction furnace is evacuated, and the temperature in the reaction furnace is adjusted to 300°C, and low-density polyethylene is introduced to make the low-density polyethylene (density 0.95g / cm 3 ) carry out fusion reaction 6min (the mass ratio of graphene film and low-density polyethylene is 100:1.5) with above-mentioned graphene film in reaction furnace, realize mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com