Outdoor mirror surface powder coating, preparation method thereof and coating formed by outdoor mirror surface powder coating

A powder coating, outdoor technology, used in powder coatings, coatings, polyester coatings, etc., can solve the problem of difficult to achieve replacement in the field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

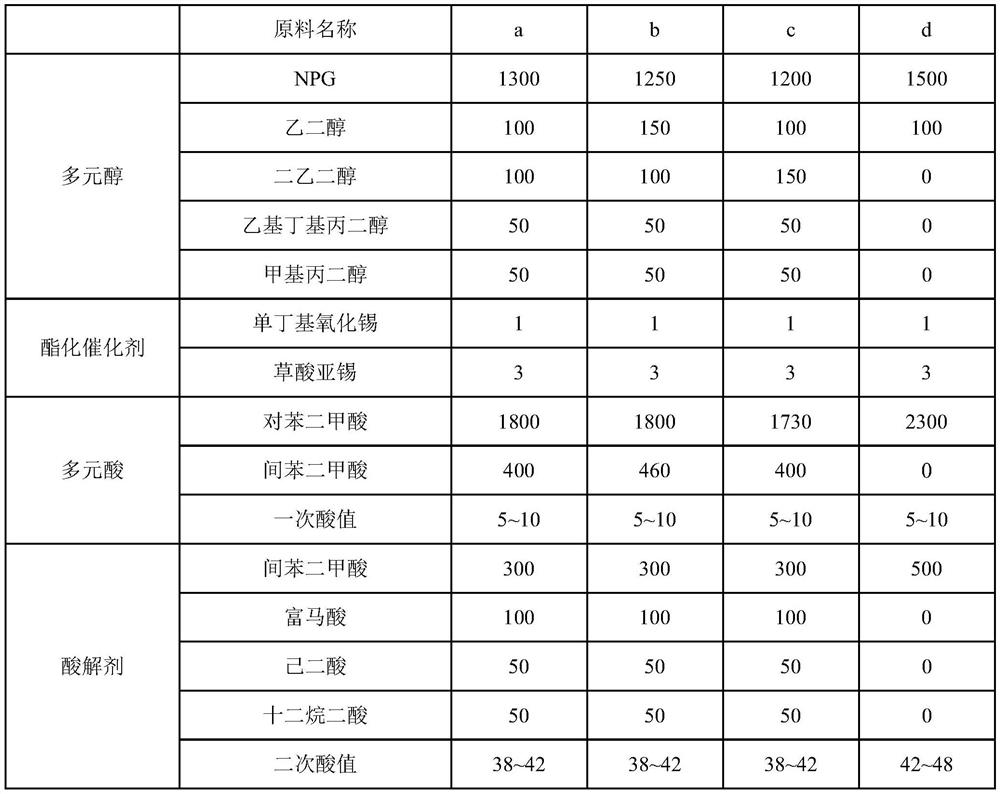

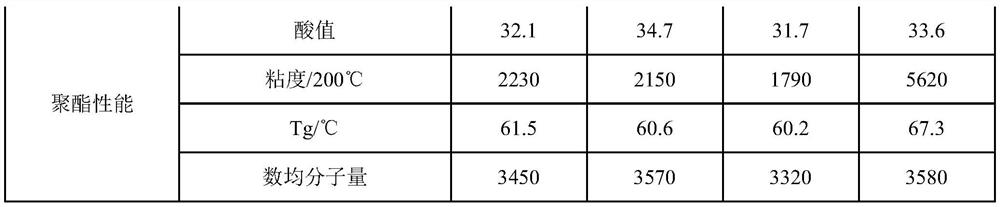

[0047] Polyester resin A

[0048]Put the polyols, aromatic acids and catalysts in the formula in Table 1 into the reaction kettle at the same time, slowly raise the temperature to 235-255°C in a nitrogen atmosphere and maintain it. After the system is clarified, take a sample to detect the acid value (AV) to reach 5-20mgKOH / Add a secondary acidolysis agent when the resin is gram and maintain the temperature at 235-250°C for acid-decapping for about 1.5-2 hours. When the acid value of the polyester is 38-42mgKOH / g resin, cool down to 215-230°C and polycondense in vacuum (~0.1MPA) for a period of time, so that the acid value of the polyester reaches 28-34mgKOH / g resin, and the viscosity is 1500-2500mPa.S / 200°C. Then cool down to 180-225°C and discharge. Wherein resin a, b and c are examples, and d is a comparative example.

[0049] Table 1 Polyester resin A raw material formula, control acid value and performance in the production process

[0050]

[0051]

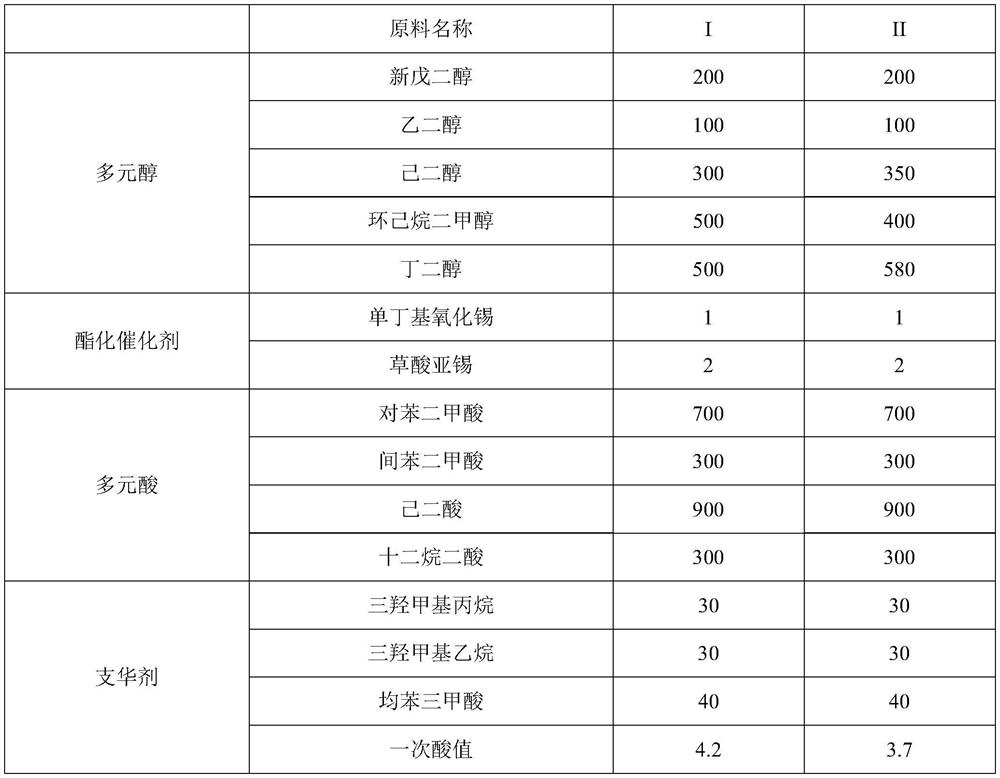

[0052] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com