Polyethylene armored drain pipe

A polyethylene and drainage pipe technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of affecting service life, high production cost, insufficient ring stiffness, etc., to increase mechanical compressive strength, improve external force resistance, Watch out for rat bites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

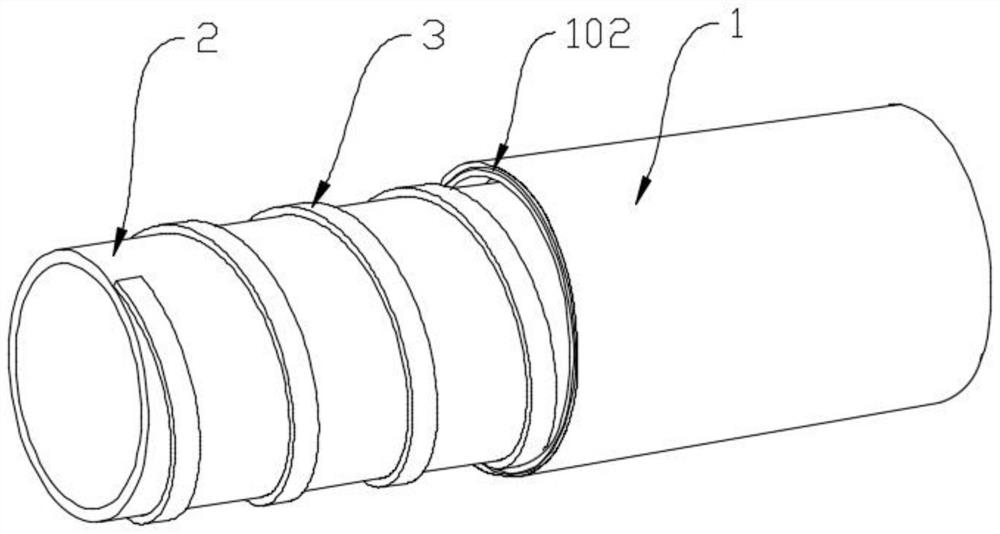

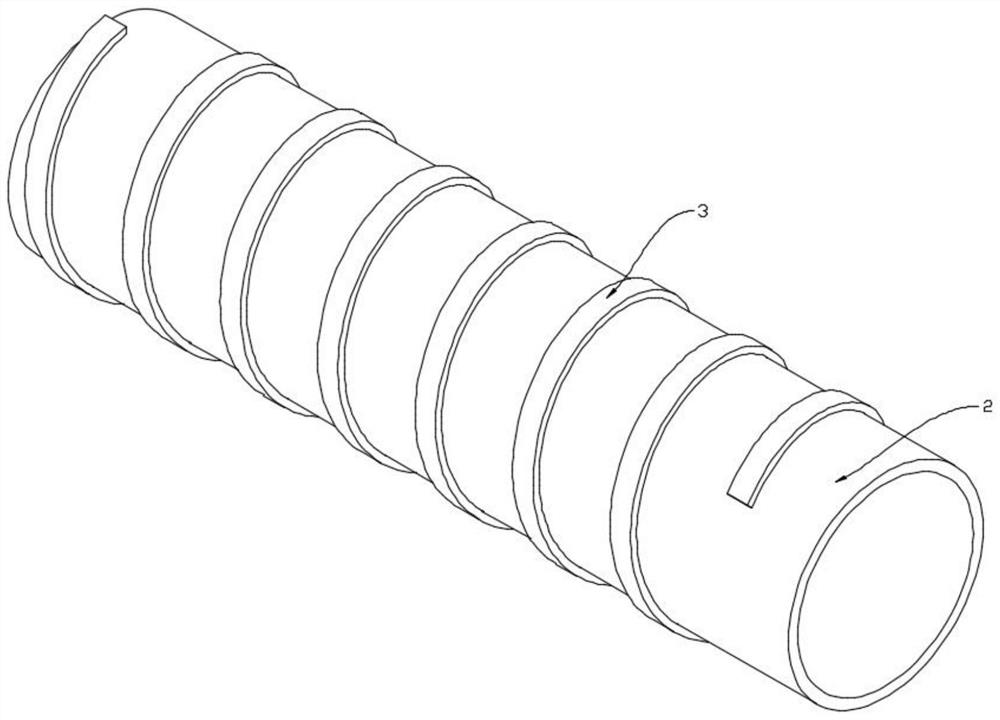

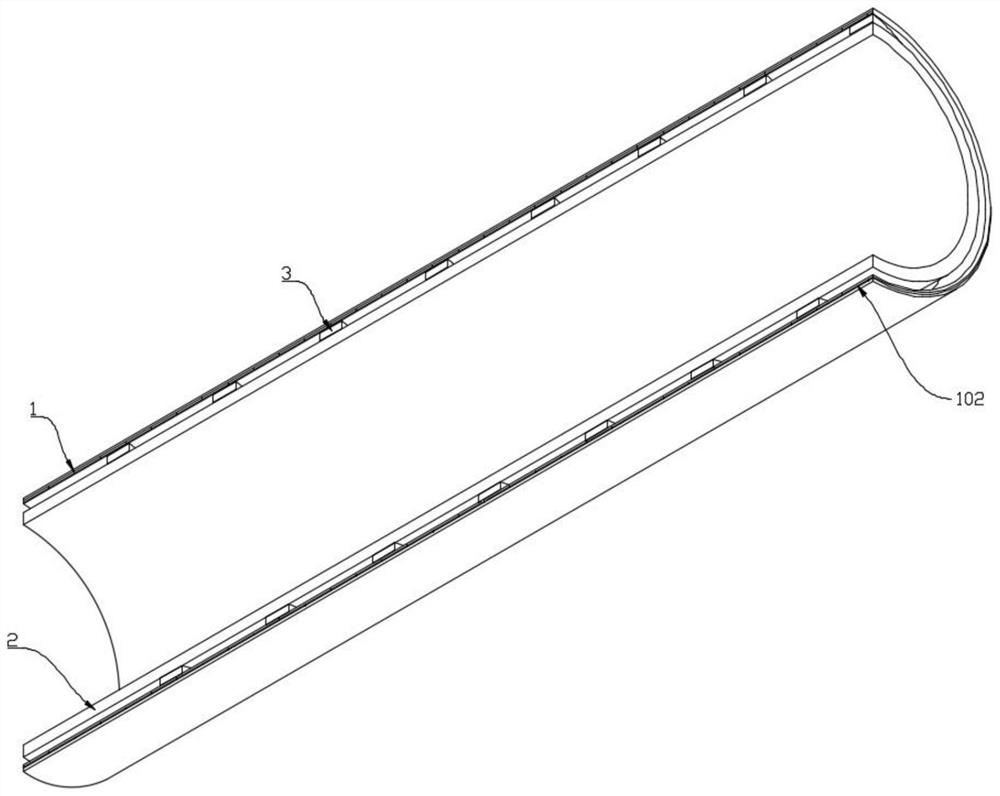

[0025] Such as Figure 1-Figure 4 as shown,

[0026] A polyethylene armored drainage pipe, including a pipe body, the pipe body includes an outer wall 1, a middle wall and an inner wall 2, and the outer wall 1 is made of steel belt or steel mesh belt and polyethylene die-casting extrusion composite The armored polyethylene layer, the outer wall 1 includes a polyethylene matrix layer 101 and an armored matrix 102, the polyethylene matrix layer 101 is a polyethylene pipe wall made of polyethylene, and the armored matrix 102 is embedded in the polyethylene matrix layer 101 inside. The armor base 102 is formed by helically winding steel strips or steel wire mesh strips. The armored matrix 102 is in the form of helical winding, and the helical angle of the armored matrix is 30-80° for helical winding, and then pressed with the polyethylene matrix layer 101 through a hot-melt extrusion die-casting process to form an integrated structure.

[0027] At the same time, in order to b...

Embodiment 2

[0031] Such as Figure 5 As shown, the structure of this embodiment is basically the same as that of Implementation 1. The difference is that the inner layer wall 2 of this embodiment is an armored polyethylene layer wall, and the inner layer wall 2 is made of steel belt or steel wire mesh belt and polyethylene heat. Made by melt extrusion die casting.

[0032] This embodiment also adopts a three-layer wall structure. The difference is that the inner wall is the working layer, and the inner wall 2 also adopts an armored polyethylene wall structure similar to the outer wall 1, which can improve the resistance of the inner layer. Internal pressure strength, suitable for water supply and drainage pipes whose inner wall needs to bear pressure, or where the inner wall is easily damaged by external force. The pipe wall of this embodiment has strong environmental adaptability, even if the inner and outer walls of the pipe are damaged by the external environment, the overall performa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com