A non-metallic mineral grouting material for road subgrade reinforcement

A technology of non-metallic minerals and grouting materials, which is applied in the field of non-metallic minerals grouting materials, can solve the problems that underground soil materials cannot be consolidated, roadbed reinforcement is useless, and grouting materials have poor adaptability, etc., and achieve water damage resistance Good, high early strength, high durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

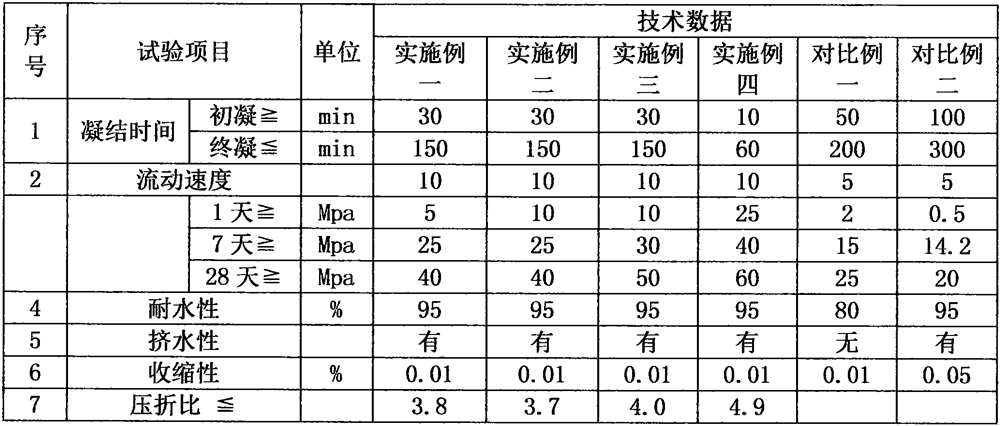

Examples

Embodiment 1

[0012] The non-metallic mineral grouting material used for road subgrade reinforcement involved in this embodiment is first made into powder form of calcined kaolin and blast furnace slag. Then add the powdered calcined kaolin, blast furnace slag powder, Shuangfei powder and additives into the dry blender according to the weight ratio, mix and stir for about 15 minutes to form a uniform dry powder, and pack it into the warehouse. The 100-mesh passing rate of the prepared powder was 99%.

[0013] The main chemical components of the selected calcined kaolin are silicon dioxide, ferric oxide and aluminum oxide. The main chemical component of the selected Shuangfei powder is calcium carbonate.

[0014] The selected blast furnace slag is blast furnace steelmaking industrial waste, the commercially available S95 granulated blast furnace slag has a density of 2.86 grams per cubic centimeter, and its main chemical components are calcium oxide, silicon dioxide and aluminum dioxide. T...

Embodiment 2

[0028] The difference between the non-metallic mineral grout for road subgrade reinforcement involved in this embodiment and the first embodiment is that the non-metallic mineral grout involved in this embodiment includes 55 parts by weight of calcined kaolin , 25 parts by weight of blast furnace slag powder, 15 parts by weight of Shuangfei powder, and 0.5 parts by weight of additives.

[0029] Further, the amount of the water-fixing coagulant is 0.3 parts by mass, the amount of the softener is 0.1 parts by mass, and the amount of the leveling agent is 0.1 parts by mass.

Embodiment 3

[0031] The difference between the non-metallic mineral grout for road subgrade reinforcement involved in this embodiment and the first embodiment is that the non-metallic mineral grout involved in this embodiment includes 60 parts by weight of calcined kaolin , 30 parts by weight of blast furnace slag powder, 20 parts by weight of Shuangfei powder, and 0.8 parts by weight of additives.

[0032] Further, the amount of the water-fixing coagulant is 0.4 parts by mass, the amount of the softener is 0.2 parts by mass, and the amount of the leveling agent is 0.2 parts by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com