A kind of preparation method of lignin polyether polyol

A lignin polyether and polyol technology, applied in the field of chemical synthesis, can solve the problems of low yield of propoxylated lignin, unsuitability for industrial production, high viscosity of polyether, etc., and achieve good compatibility and stable size High performance and high mechanical compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

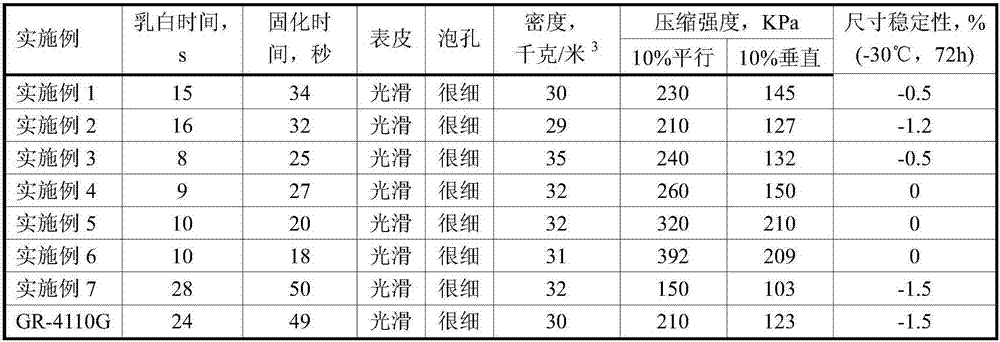

Examples

Embodiment 1

[0039] Preparation of lignin polyether polyols:

[0040] (1) Add 200g of glycerin, 200g of sucrose and 10g of dimethylamine into the closed reaction kettle, and replace the air in the reaction kettle with nitrogen. After the temperature is raised to 100°C, slowly add 300g of propylene oxide to control the pressure inside the reaction kettle Less than 0.4MPa, due to the exothermic reaction, open the cooling water tube to cool down, and keep the temperature at 90-100°C. After adding propylene oxide, in order to completely react the propylene oxide in the gas phase in the reactor, proceed at a stirring rate of 18rpm The first section stirred and reacted for 3 hours;

[0041] (2) After reducing the pressure to 0.05MPa, degas for 1 hour;

[0042] (3) Then add 20g of sodium lignosulfonate, and slowly add the remaining 500 grams of propylene oxide, control the pressure in the reactor to be less than 0.4MPa, and the reaction temperature is 110-115°C. After adding propylene oxide, in ...

Embodiment 2

[0046] Preparation of lignin polyether polyols:

[0047] (1) Add 300 grams of glycerin and 10 grams of dimethylethanolamine into a closed reaction kettle, and replace the air in the reaction kettle with nitrogen. After the temperature is raised to 80°C, slowly add 184 g of propylene oxide to control the pressure inside the reaction kettle No more than 0.4MPa. Due to the exothermic reaction, open the cooling water tube to cool down, and control the reaction temperature at 90-100°C. After adding propylene oxide, in order to completely react the propylene oxide in the gas phase in the reactor, the stirring rate at 18rpm The next first section stirred and reacted for 2 hours;

[0048] (2) Then after the pressure drops to 0.01MPa, degas for 0.5 hours;

[0049] (3) Then add 150g of sodium lignosulfonate, and slowly add the remaining propylene oxide 736g, control the pressure in the reactor to not exceed 0.4MPa, and the reaction temperature is 100-110°C. After adding propylene oxide...

Embodiment 3

[0053] Preparation of lignin polyether polyols:

[0054] (1) Add 30g of glycerol, 60g of sucrose, 50g of sorbitol, 8g of N,N'-dimethyl 1,3 propylenediamine, and 8g of aminoethylpiperazine into the closed reaction kettle, and replace them with nitrogen After the air in the reactor is heated up to 90°C, slowly add 150g of butylene oxide to control the pressure inside the reactor to be less than 0.4MPa. Due to the exothermic reaction, open the coil to cool down the cooling water, and control the temperature at 90-100°C. After finishing the butylene oxide, in order to make the butylene oxide in the gas phase in the reactor react completely, the first section of the reaction was stirred for 2 hours at a stirring rate of 18rpm;

[0055] (2) Then the pressure drops to -0.05MPa, degassing for 0.5 hours;

[0056] (3) Then add 250g of sodium lignosulfonate, and slowly add the remaining 480g of butylene oxide, control the pressure in the reactor to be less than 0.4MPa, and the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com