Improvement method of salinized soil for highway construction

A technology for highway construction and saline soil, applied in chemical instruments and methods, applications, building structures, etc., can solve the problems of incomplete isolation, difficult construction, and high engineering costs, and achieve simple construction methods, low costs, and restraint. The effect of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

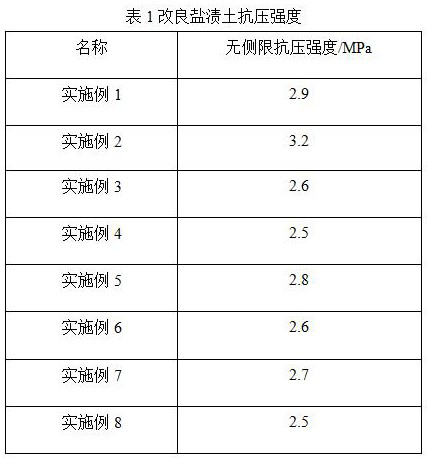

Examples

Embodiment 1

[0017] First, 30 g of acrylamide was dissolved in 41 g of water, and after stirring, 23 g of acrylic acid was added, and after stirring at 25 ° C for 20 min, 8 G polyoxyethylene ether was added to the above solution, stirred and dissolved, and labeled a solution The other 0.5 g of ammonium sulfate and sodium hydrogen sulfite were added to 32 g of water, and after stirring at 30 ° C, a 1 G crosslinker N, N methylene bisacrylamide, stirred and dissolved, and labeled B Solution. The solution A was added to 1000 g of saline soil, and mixed well and mixed well. After sealed 2 h at room temperature, then the B solution was added, and after mixing well, the obtained modified saline soil was placed in the mold, pressed into a cylinder. The test piece was then maintained at room temperature for 2 days, and there was no supened compressive strength.

Embodiment 2

[0019] First, 42 g of acrylamide was dissolved in 60 g of water, and after stirring, 15 g of methyl methacrylate was added, and after stirring at 30 ° C for 20 min, 5 g of polyvinyl alcohol was added to the above solution, stirred and dissolved, and labeled For a solution; another 0.3 g of ammonium sulfate and sodium hydrogen sulfite, after stirring at 40 ° C, 0.8 g of crosslinking agent N, N methylene bis acrylamide, stirred, and labeled The B solution. The solution A was added to 1000 g of saline soil, and mixed well and mixed well. After sealed 2 h at room temperature, then the B solution was added, and after mixing well, the obtained modified saline soil was placed in the mold, pressed into a cylinder. The test piece was then maintained at room temperature for 2 days, and there was no supened compressive strength.

Embodiment 3

[0021] First, 35 g of sodium acrylate was dissolved in 35 g of water, and after stirring, 25 g of maleic anhydride was added, and after stirring at 40 ° C for 20 min, 2 g of polyvinyl alcohol and 2 g of polyoxyethylene ether were added to the above solution, thoroughly stirred Dissolve, and labeled a solution; another 1.2 g of ammonium sulfate and sodium hydrogen sulfite was added to 37 g of water, and after stirring at 40 ° C, the 1.5 G crosslinking agent N, N methylene bis acrylamide, The mixture was dissolved and labeled a B solution. The solution A was added to 1000 g of saline soil, and mixed well and mixed well. After sealed 2 h at room temperature, then the B solution was added, and after mixing well, the obtained modified saline soil was placed in the mold, pressed into a cylinder. The test piece was then maintained at room temperature for 2 days, and there was no supened compressive strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com