Automatic double-speed control motor after secondary electrification

A control relay, two-speed technology, applied in the direction of DC motor rotation control, excitation or armature current control, connection with control/drive circuit, etc. , to achieve the effect of improving material utilization and work efficiency, improving work mode and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

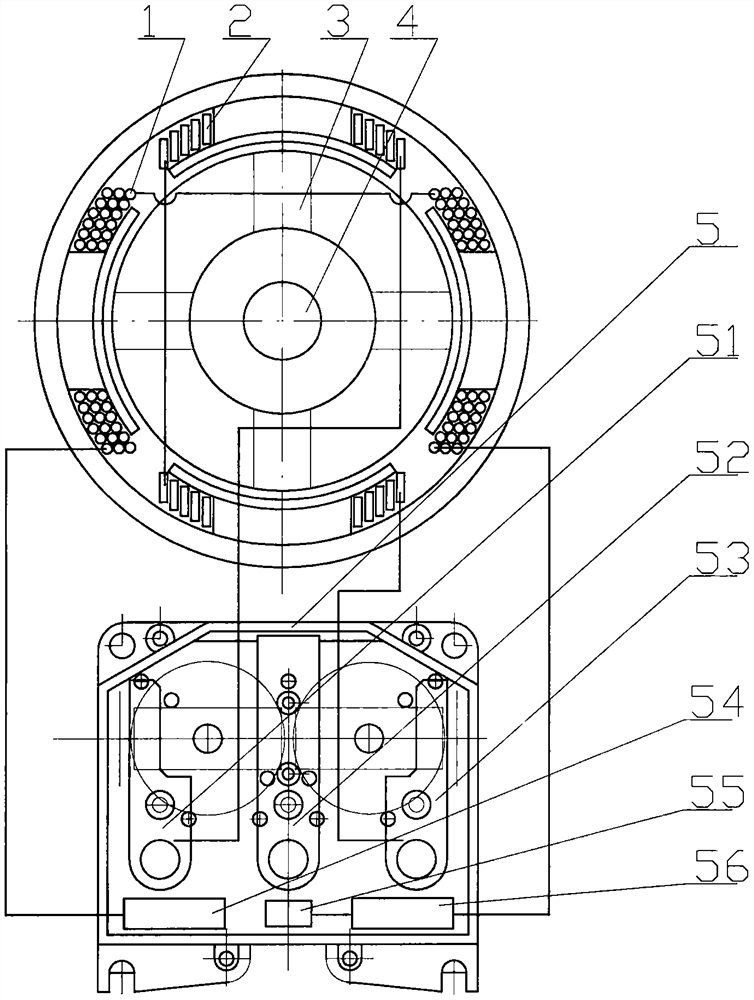

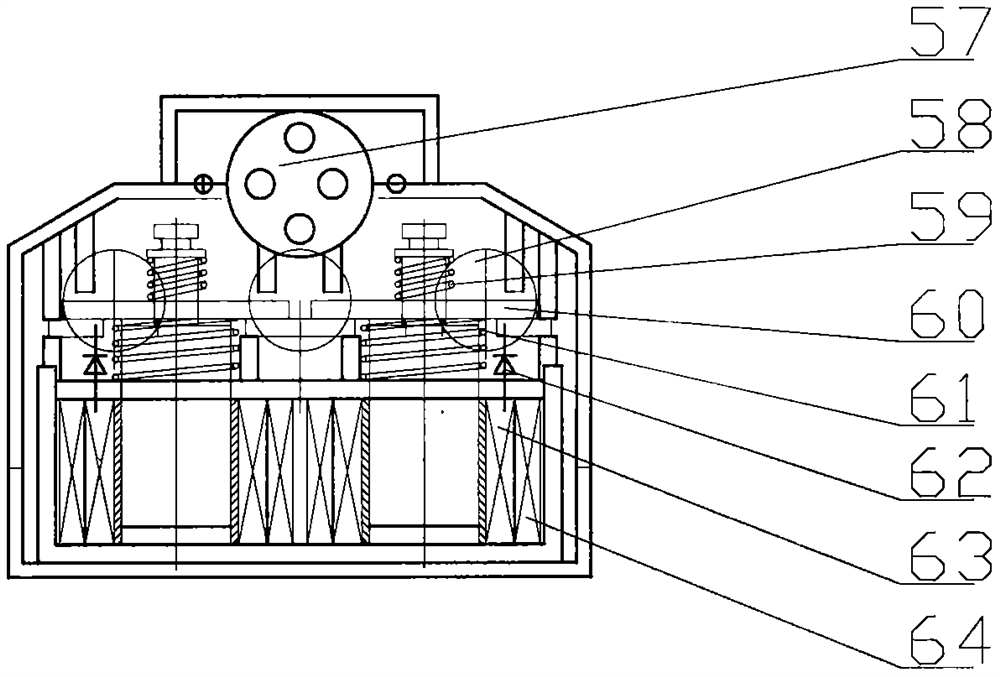

[0012] The automatic two-speed control motor after secondary power-on of the present invention, as attached figure 1 and figure 2 As shown, it includes: motor excitation soft coil (1), motor excitation hard coil (2), brush (3), motor rotor (4), control box (5), reverse contactor copper strip (51), Siamese copper bar (52), forward contactor copper bar (53), direction relay (54), secondary reverse controller (55), control relay (56), control connector (57), waterproof pull Take off (58), overtravel spring (59), moving contact (60), breaking spring (61), diode (62), pull-in coil (63), hold coil (64) and coil keel, iron bar and iron core. The automatic two-speed control motor after the second power-on is applied to the electric winch of the car and the hydraulic unit of the electric stacker. The motor excitation soft coil (1) is composed of multiple strands of enamelled thin wires and arranged symmetrically from left to right, because the enamelled thin wires The area is small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com