Building block splicing type modular ventilation and noise reduction structure

A modular, building-block technology, used in cooling/ventilation devices, cooling/ventilation/heating renovations, electrical equipment structural parts, etc., can solve problems such as noise pollution, facilitate manufacturing and assembly, reduce product costs, and reduce installation and lifting. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

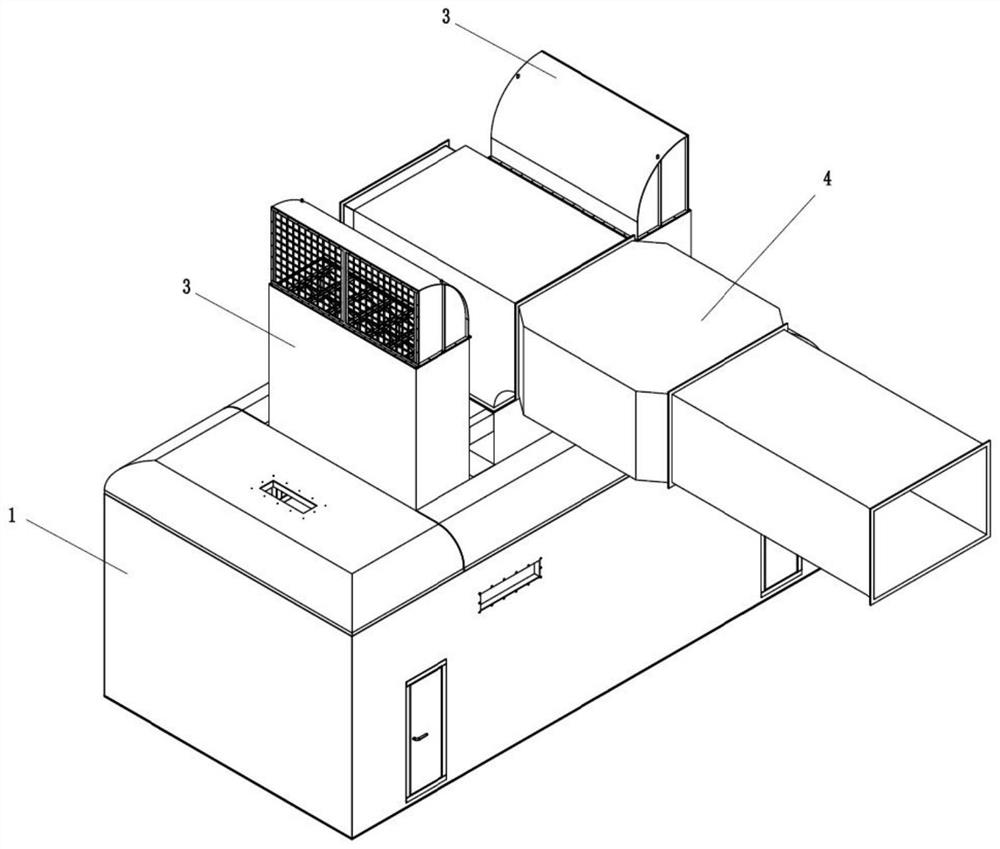

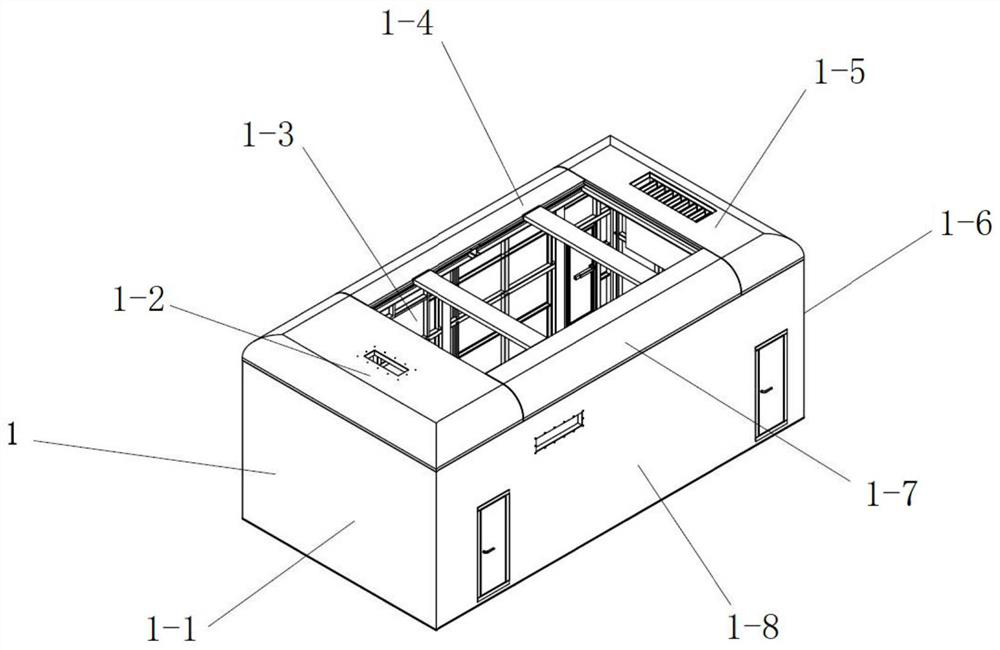

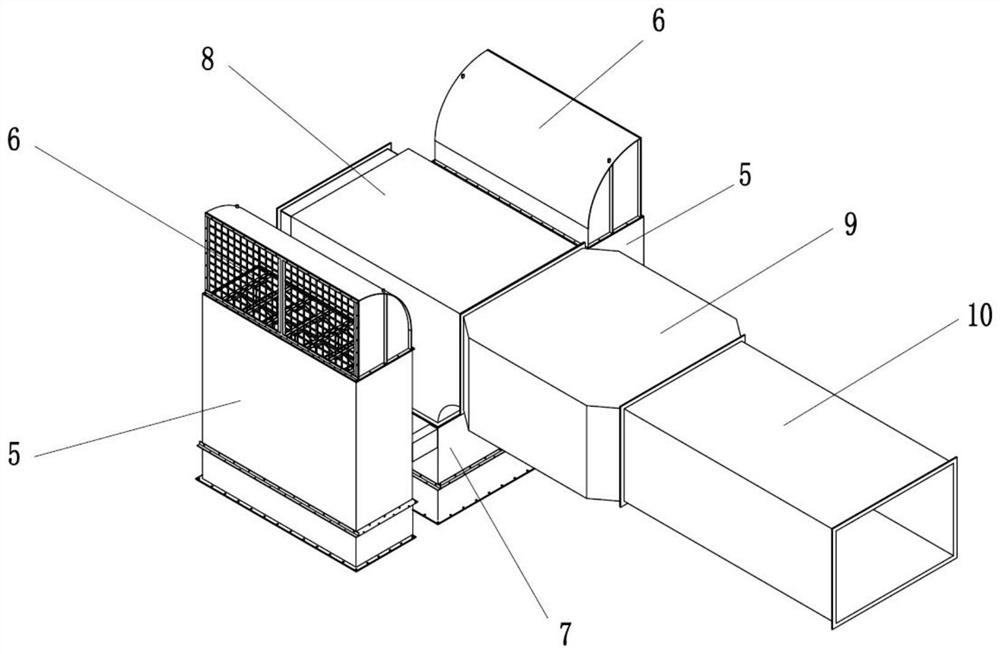

[0020] What this embodiment provides is the modularized ventilation and noise reduction structure of building blocks, such as figure 1 As shown, the soundproof cover 1 is arranged on the outside of the machine base, the bottom is connected to the base of the machine base, and the top opening leaves the installation area for the soundproof air duct 2; the soundproof cover 1 itself is spliced by 8 modules, as shown in figure 2 As shown, including module 1-1, module 1-2, module 1-3, module 1-4, module 1-5, module 1-6, module 1-7, module 1-8, the modules are all plate-shaped frames Structure, the modules are fixedly connected by bolts, and the frame of each module is filled with sound-absorbing materials to achieve sound insulation and noise reduction effects. Lifting points can be set on each module for quick and easy installation and disassembly;

[0021] The soundproof air duct 2 is arranged on the top of the machine base, and is connected and fixed with the machine base bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com