Open type structure digital control system of remote network monitoring and secondary development

An open-structure, secondary development technology, applied in general control systems, control/regulation systems, electrical program control, etc., can solve problems such as failure to consider large-flow signal data flow transmission requirements, deficiencies, and damage to system stability. , to achieve the effect of enhancing the diagnostic capability of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Below in conjunction with accompanying drawing, the implementation of the present invention is described as follows:

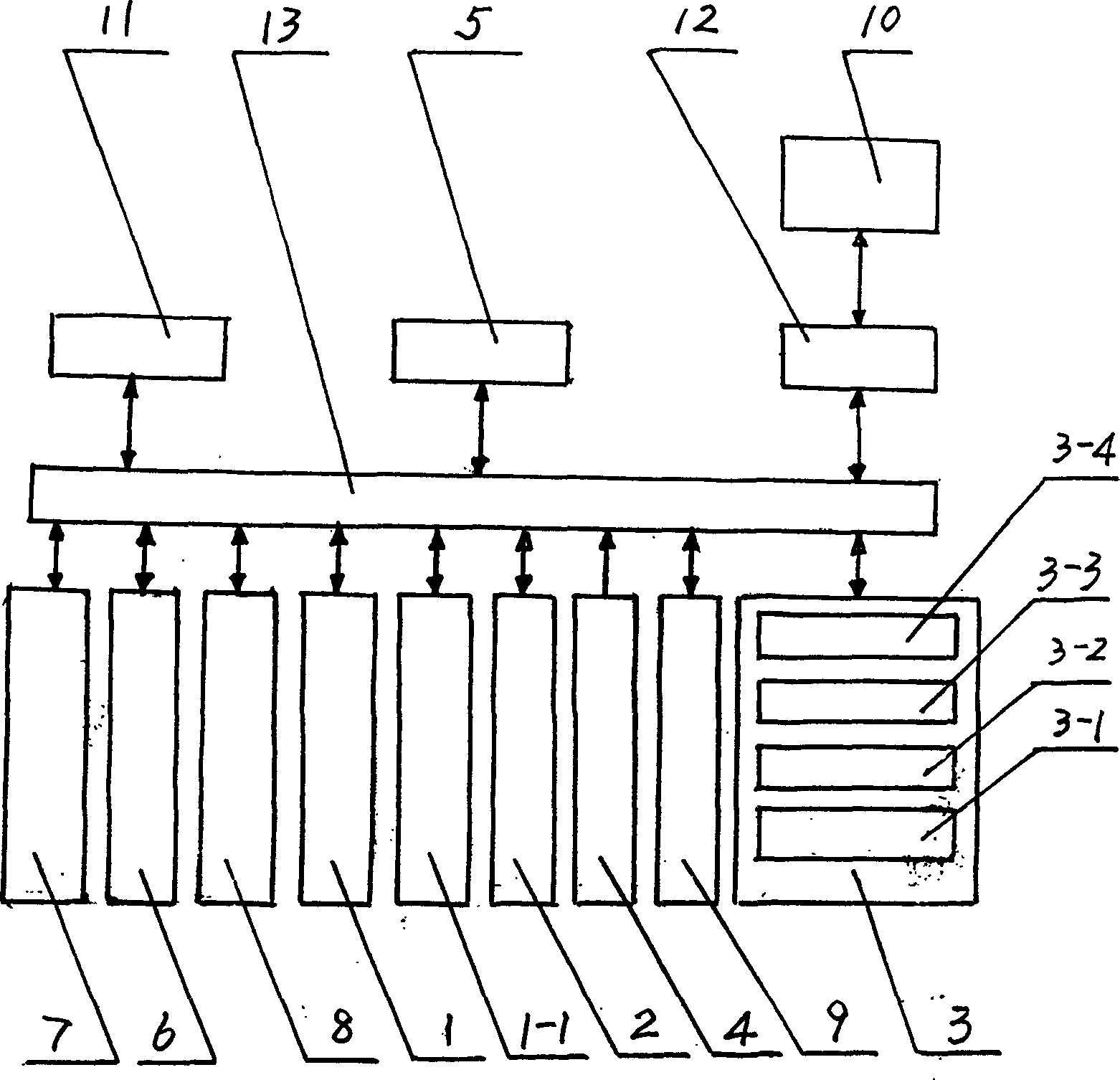

[0079] exist figure 1 Among them, central microprocessor 1, high-speed DSP processing chip 1-1, general control and interactive management chip 2, memory 3, power clock circuit 4, general control and user interaction interface 5, status monitoring and fault diagnosis chip 6, network management Control chip 7, data resource management chip 8, secondary development simulation control chip 9, network and remote control interface 11, secondary development simulation interface 12 are respectively connected to system bus 13; PC-based CNC system secondary development platform 10 It is connected with the secondary development simulation interface 12 by the bus 13 . The memory 3 is composed of a system working ROM memory chip 3-1, a data storage FLASH-ROM memory chip 3-2, a simulation development RAM memory chip 3-3 and a secondary development FLASH-ROM memory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com