Preparation process of sterilized lidocaine hydrochloride injection packaged by plastic ampoule

A technology of lidocaine hydrochloride and preparation process, which is applied in the research field of lidocaine hydrochloride sterilization process and packaging materials, can solve the problems of inconvenient transportation of glass ampoules, easy adverse events caused by clinical use, large loss, etc., and achieve the reduction of particles The risk of contamination, good sealing performance, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

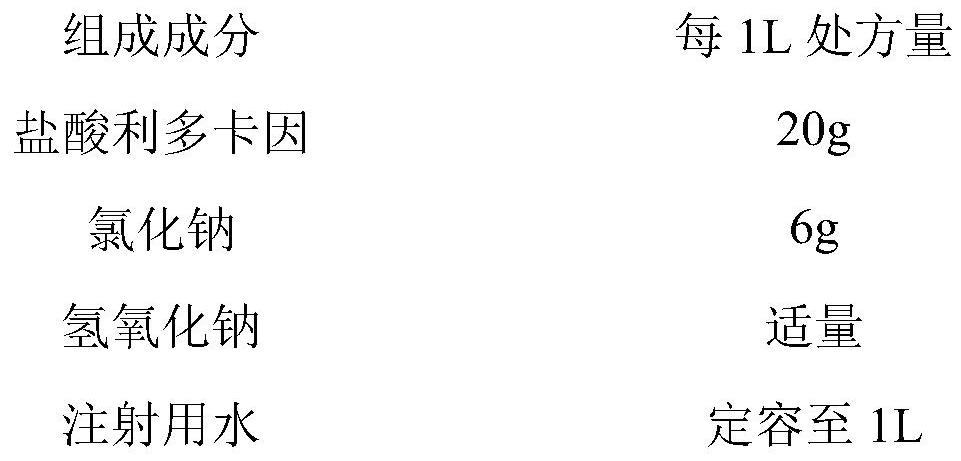

[0022] Preparation of lidocaine hydrochloride injection

[0023]

[0024] ①Put 80L of water for injection into the liquid mixing tank, and the temperature of the water for injection is 30°C-90°C.

[0025] ②Add sodium chloride and lidocaine hydrochloride into the liquid mixing tank and stir to dissolve completely.

[0026] ③ Use 1mol / L sodium hydroxide solution to adjust the pH of the solution to 4.0-6.0.

[0027] ④Add water for injection to make up to 1L.

[0028] ⑤ The liquid medicine is filtered through 0.45μm and 0.22μm microporous cartridge filters.

[0029] ⑥ The liquid medicine is filled in polypropylene ampoules.

[0030] ⑦The medicinal solution is sterilized by hot water, and the sterilization conditions are 121°C and 15min.

Embodiment 2

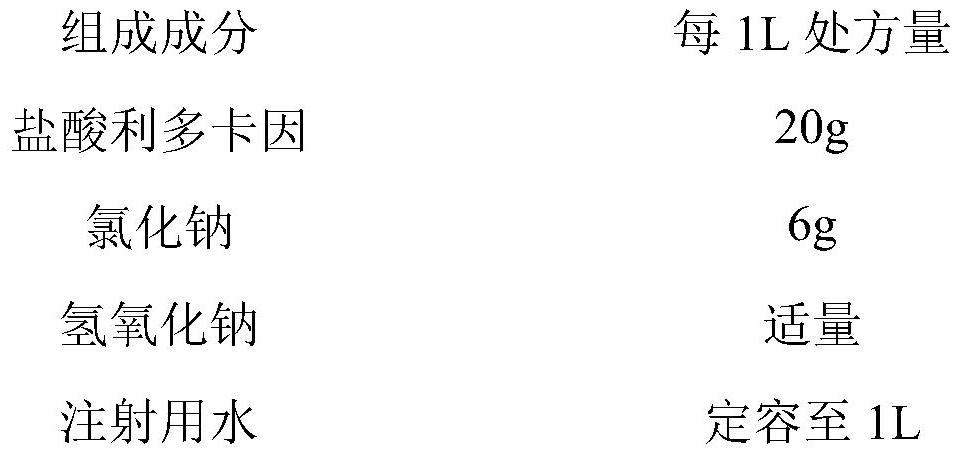

[0031] (2) embodiment 2 prepares lidocaine hydrochloride injection

[0032] Preparation of lidocaine hydrochloride injection

[0033]

[0034] ①Put 80L of water for injection into the liquid mixing tank, and the temperature of the water for injection is 30°C-90°C.

[0035] ②Add sodium chloride and lidocaine hydrochloride into the liquid mixing tank and stir to dissolve completely.

[0036] ③ Use 1mol / L sodium hydroxide solution to adjust the pH of the solution to 4.0-6.0.

[0037] ④Add water for injection to make up to 1L.

[0038] ⑤ The liquid medicine is filtered through 0.45μm and 0.22μm microporous cartridge filters.

[0039] ⑥ The liquid medicine is filled in glass ampoules.

[0040] ⑦The medicinal solution is sterilized by hot water, and the sterilization conditions are 121°C and 15min.

Embodiment 3

[0041] (3) embodiment 3 prepares lidocaine hydrochloride injection

[0042] Preparation of lidocaine hydrochloride injection

[0043]

[0044] ①Put 80L of water for injection into the liquid mixing tank, and the temperature of the water for injection is 30°C-90°C.

[0045] ②Add sodium chloride and lidocaine hydrochloride into the liquid mixing tank and stir to dissolve completely.

[0046] ③ Use 1mol / L sodium hydroxide solution to adjust the pH of the solution to 4.0-6.0.

[0047] ④Add water for injection to make up to 1L.

[0048] ⑤ The liquid medicine is filtered through 0.45μm and 0.22μm microporous cartridge filters.

[0049] ⑥ The liquid medicine is filled in polypropylene ampoules.

[0050] ⑦ The liquid medicine is sterilized by high-pressure steam, and the sterilization conditions are 121°C and 12min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com